CALIBRATION USING MODEL 263 CALIBRATOR/SOURCE

INTRODUCTION

The following paragraphs provide detailed procedures to

calibrate the Model 617 using the Model 263 Calibrator/

Source. Most of the calibration procedures are digital in

nature and can be done from the front panel or over the

IEEE-488 bus.

To calibrate the instrument from the front panel, perform

the following procedures, omitting paragraph “IEEE-488

Bus Digital Calibration”. To calibrate the Model 617 over

the IEEE-488 bus, perform the following procedures, omit-

ting paragraph “Front Panel Digital Calibration’:

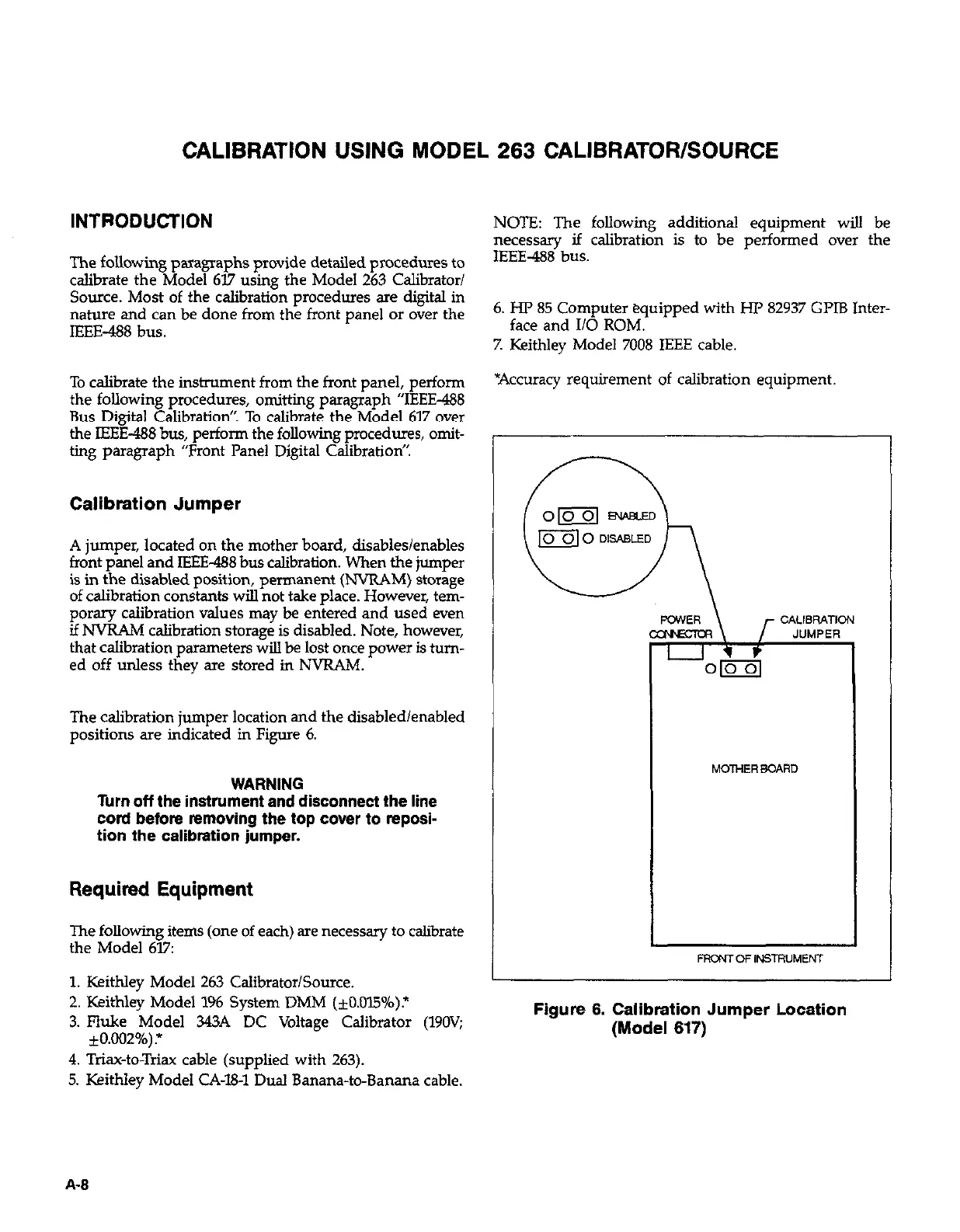

Calibration Jumper

A jumper, located on the mother board, disables/enables

front panel and IEEE-488 bus calibration. When the jumper

is in the disabled position, permanent (NVRAM) storage

of calibration constants will not take place. However, tem-

porary calibration values may be entered and used even

if NVRAM calibration storage is disabled. Note, however,

that calibration parameters will be lost once power is turn-

ed off unless they are stored in NVRAM.

The calibration jumper location and the disabled/enabled

positions are indicated in Figure 6.

WARNING

Turn off the instrument and disconnect the line

cord before removing the top cover to reposi-

tion the calibration jumper.

Required Equipment

The following items (one of each) are necessary to calibrate

the Model 617:

1. Keithley Model 263 Calibrator/Source.

2. Keithley Model 196 System DMM (+O.OlS%).*

3. Fluke Model 343A DC Voltage Calibrator (190V;

*0.002%)?

4. Triaw-to-Triax cable (supplied with 263).

5. Keithley Model CA-W1 Dual Banana-to-Banana cable.

NOTE: The following additional equipment will be

necessary if calibration is to be performed over the

IEEE-488 bus.

6. HP 85 Computer equipped with HP 82937 GI’IB Inter-

face and Ii0 ROM.

7. Keithley Model 7008 IEEE cable.

*Accuracy requirement of calibration equipment

MOTHERBOARD

Figure 6. Calibration Jumper Location

(Model 617)

A-8

Loading...

Loading...