1

-I

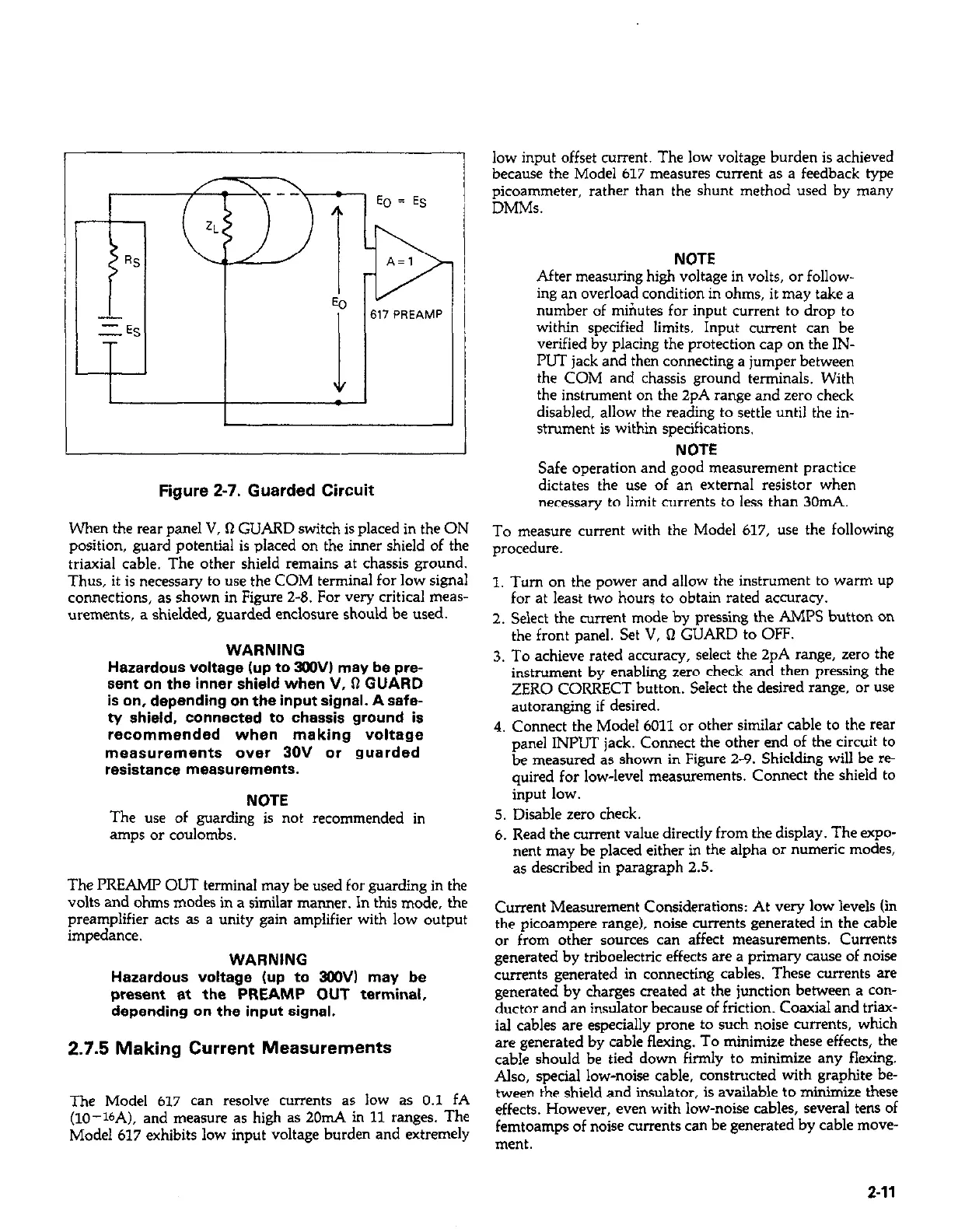

Figure 2-7. Guarded Circuit

When the rear panel V, Q GUARD switch is placed in the ON

position, guard potential is placed on the inner shield of the

triaxial cable. The other shield remains at chassis ground.

Thus, it is necessary to use the COM terminal for low signal

connections, as shown in Figure 2-0. For very critical meas-

urements, a shielded, guarded enclosure should be used.

WARNING

Hazardous voltage lup to 3OOV) may be pre-

sent on the inner shield when V, Q GUARD

is on, depending on the input signal. A safe-

ty shield, connected to chassis ground is

recommended when making voltage

measurements over 30V or guarded

resistance measurements.

NOTE

The use of guarding is not recommended in

amps or coulombs.

The PREAMI’ OLJT terminal may be used for guarding in the

volts and ohms modes in a similar manner. In this mode, the

preamplifier acts as a unity gain amplifier with low output

impedance.

WARNING

Hazardous voltage (up to 3WV) may be

present at the PREAMP OUT terminal,

depending on the input signal.

2.7.5 Making Current Measurements

The Model 617 can resolve currents as low as 0.1 fA

(lo--lbA), and measure as high as 2011~4 in 11 ranges. The

Model 617 exhibits low input voltage burden and extremely

low input offset current. The low voltage burden is achieved

because the Model 617 measures current as a feedback type

picoammeter, rather than the shunt method used by many

DMMs.

NOTE

After measuring high voltage in volts, or follow-

ing an overload condition in ohms, it may take a

number of miriutes for input current to drop to

within specified limits. Input current can be

verified by placing the protection cap on the IN-

PUT jack and then connecting a jumper between

the COM and chassis ground terminals, With

the instrument on the 2pA range and zero check

disabled, allow the reading to settle until the in-

strument is within specifications.

NOTE

Safe operation and good measurement practice

dictates the use of an external resistor when

necessary to limit currents to less than 3011~4.

To measure current with the Model 617, use the following

procedure.

I. Turn on the power and allow the instrument to warm up

for at least two hours to obtain rated accuracy.

2. Select the current mode by pressing the AMPS button on

the front panel. Set V, Q GUARD to OFF.

3. To achieve rated accuracy, select the 2pA range, zero the

instrument by enabling zero check and then pressing the

ZERO CORRECT button. Select the desired range, or use

autoranging if desired.

4. Connect the Model 6011 or other similar cable to the rear

panel INPUT jack. Connect the other end of the circuit to

be measured as shown in Figure 2-9. Shielding will be re-

quired for low-level measurements. Connect the shield to

input low.

5. Disable zero check.

6. Read the current value directly from the display. The expo-

nent may be placed either in the alpha or numeric modes,

as described in paragraph 2.5.

Current Measurement Considerations: At very low levels (in

the picoampere range), noise currents generated in the cable

or from other sources can affect measurements. Currents

generated by triboelectric effects are a primary cause of noise

currents generated in connecting cables. These currents are

generated by charges created at the junction between a con-

ductor and an insulator because of friction. Coaxial and triax-

ial cables are especially prone to such noise currents, which

are generated by cable flexing. To minimize these effects, the

cable should be tied down firmly to minimize any flexing.

Also, special low-noise cable, constructed with graphite be-

tween the shield and insulator, is available to minimize these

effects. However, even with low-noise cables, several tens of

femtoamps of noise currents can be generated by cable move-

ment.

2-11

Loading...

Loading...