6 FORK, TRIPLE CLAMP 25

201485-10

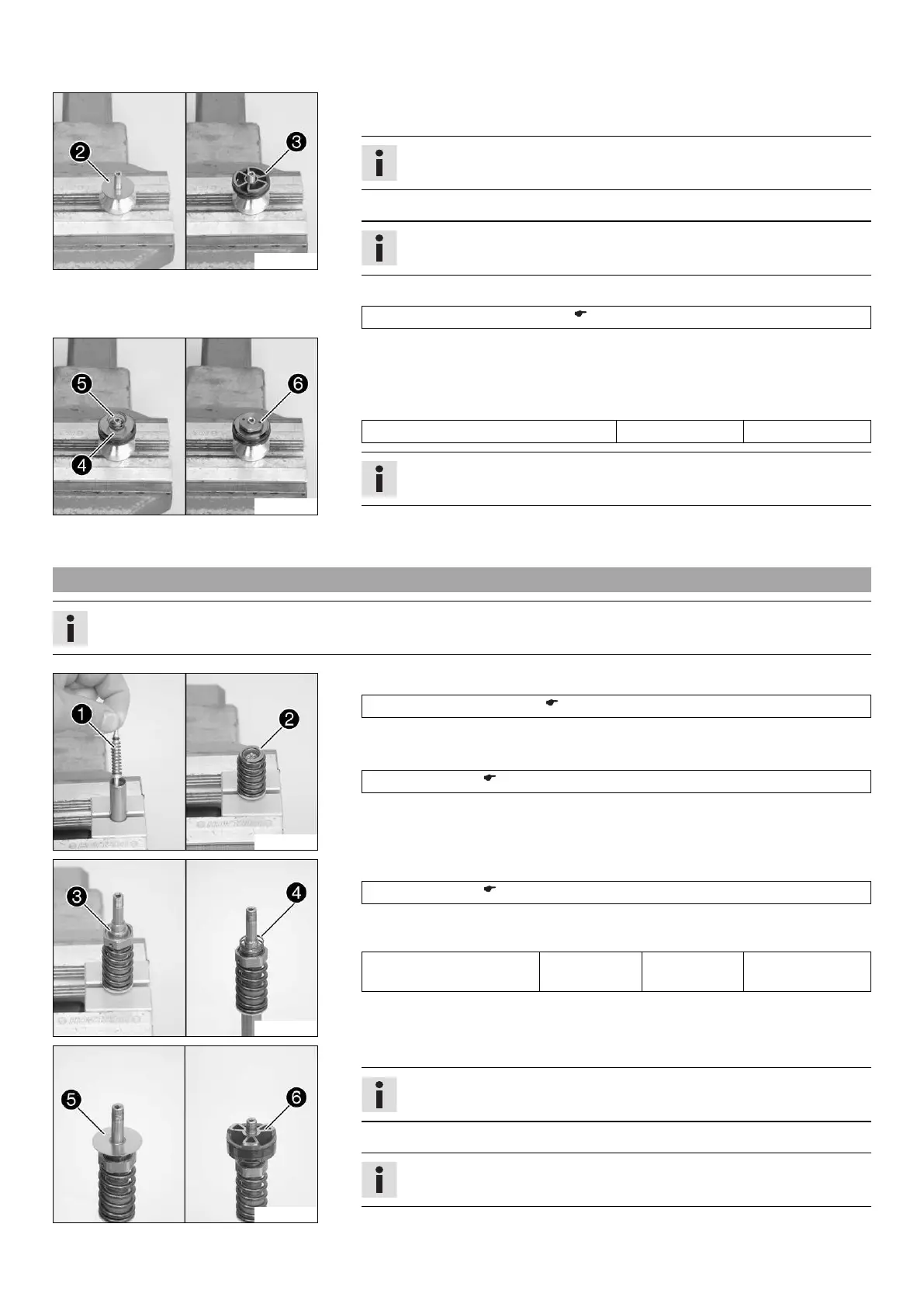

– Clamp the tap compression in a bench vise using soft jaws.

– Mount shim stack 2.

Info

Mount the smaller shims below.

– Mount pistons 3 with O-ring.

Info

The side with the largest inside diameter faces upward.

– Grease the piston O-ring.

Fork oil (SAE 4) (48601166S1) ( p. 211)

201486-10

– Mount washer 4.

– Mount spring 5 with the tighter coil facing downward.

– Mount and tighten the nut 6.

Guideline

Tap compression nut M6x0.5 3 Nm (2.2 lbf ft)

Info

Washer 4 must be free to move against the spring force.

– Lock the nut using a punch.

– Extract the tap compression.

6.15 Assembling the cartridge

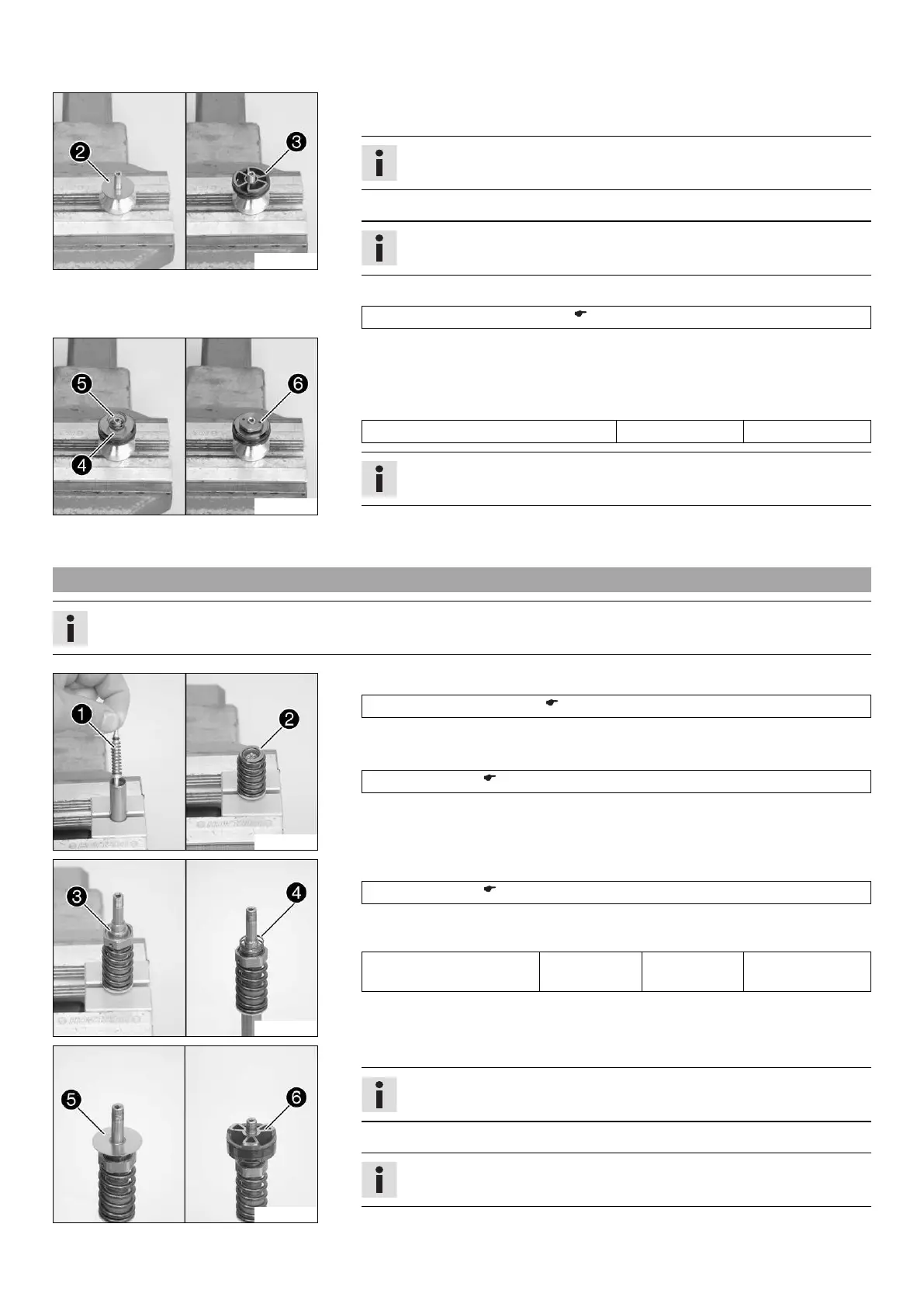

Info

The steps are identical for both fork legs.

200715-10

– Clamp in the piston rod.

Clamping stand (T14016S) ( p. 224)

– Mount valve 1 of the rebound damping, with the spring and O-ring.

– Lubricate the O-ring.

Lubricant (T158) ( p. 212)

– Mount spring 2.

200718-10

– Grease the O-ring of tap rebound 3.

Lubricant (T158) ( p. 212)

– Mount and tighten the tap rebound.

Guideline

Tap rebound M9x1 18 Nm

(13.3 lbf ft)

Loctite

®

2701

– Position spring 4.

200719-10

– Mount shim stack 5.

Info

Mount the smaller shims below.

– Press the shim stack downward against the spring force.

Info

The shim stack must be pressed downward over the collar.

Loading...

Loading...