3. INSPECTION/ADJUSTMENT

3-16

DINK50/125

VALVE CLEARANCE(DINK 50)

Remove the met-in box and center cover.

Remove cylinder head cover.

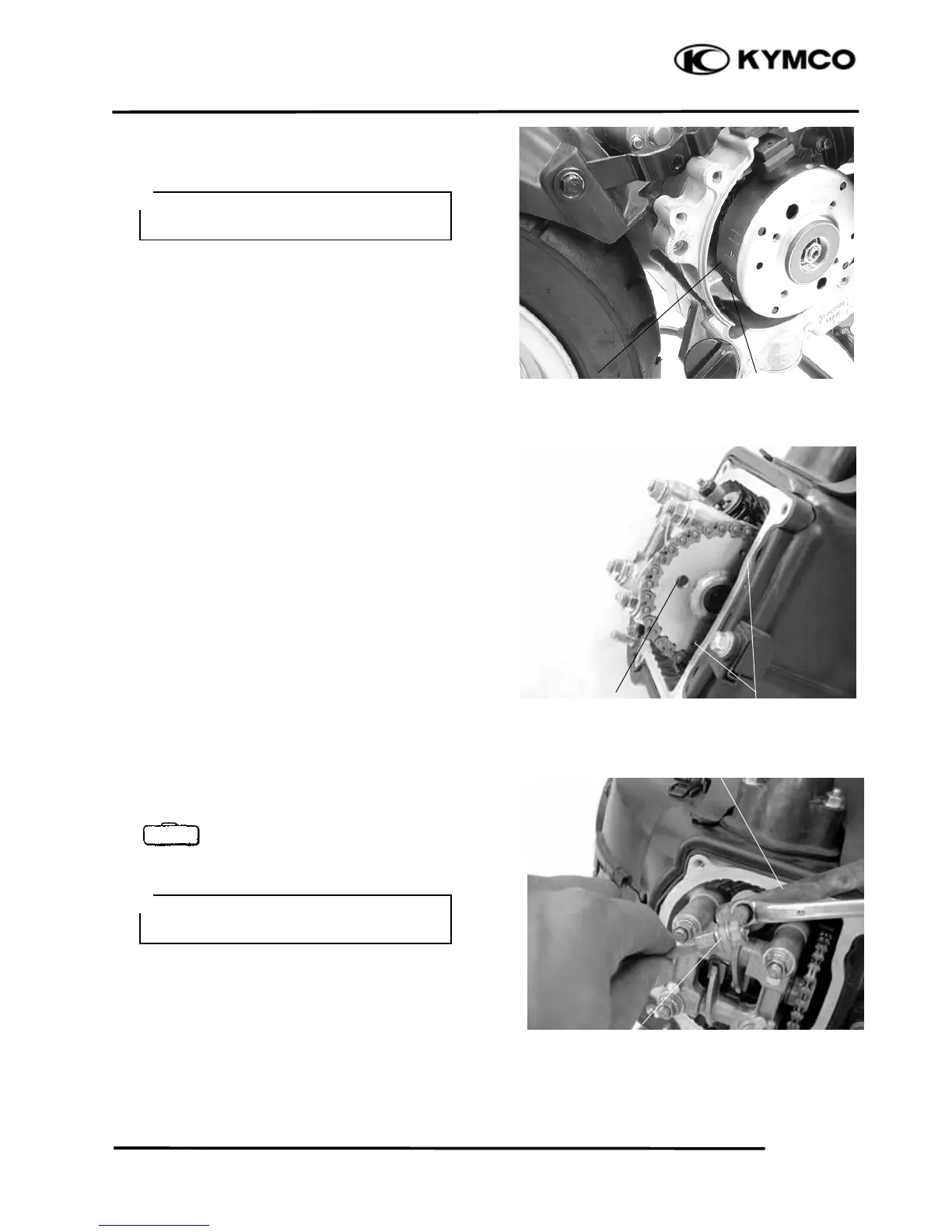

Turn the A.C. generator flywheel to the top

dead center (TDC) on the compression stroke

so that the “T” mark on the flywheel aligns

with the index mark on the right crankcase.

The time marks on the cam sprocket must be

flush with the cylinder head surface and

round hole on the cam sprocket must be

facing up as shown.

If the round hole on the cam sprocket are

facing down, turn the crankshaft clockwise

one full turn and realign the timing marks

with the cylinder head surface so it is facing

up.

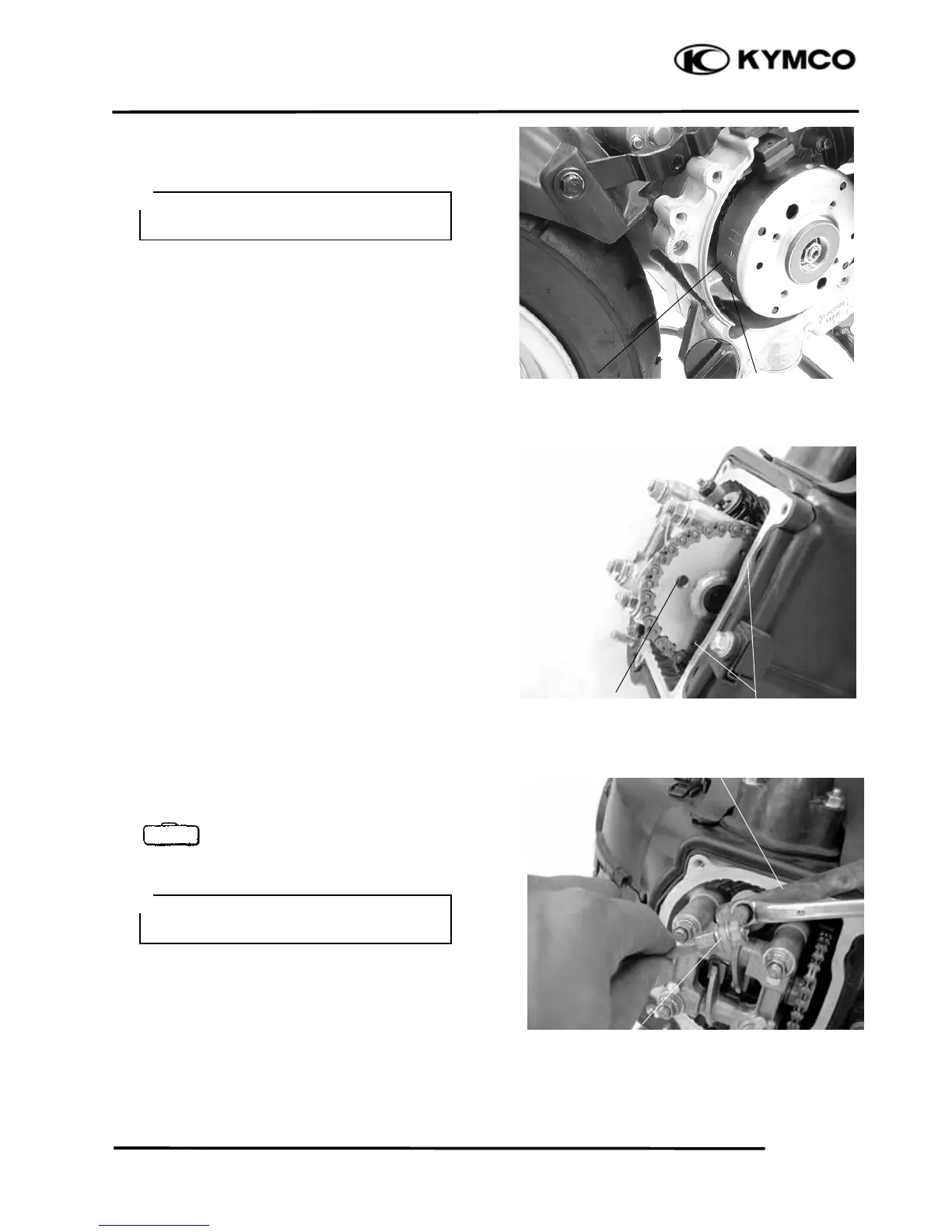

Insert a thickness gauge between the valve

stem end and the adjusting screw on the

rocker arm.

If the clearance is out of specification, bring

it into the specified range.

Valve Clearance: IN: 0.04~0.06mm

EX: 0.04~0.06mm

Loosen the lock nut and adjust by turning the

adjusting nut

Valve Adjuster E036

• Inspect and adjust valve clearance

while the engine is cold (below 35℃).

*

Special

• Check the valve clearance again afte

Loading...

Loading...