3. INSPECTION/ADJUSTMENT

3-17

DINK50/125

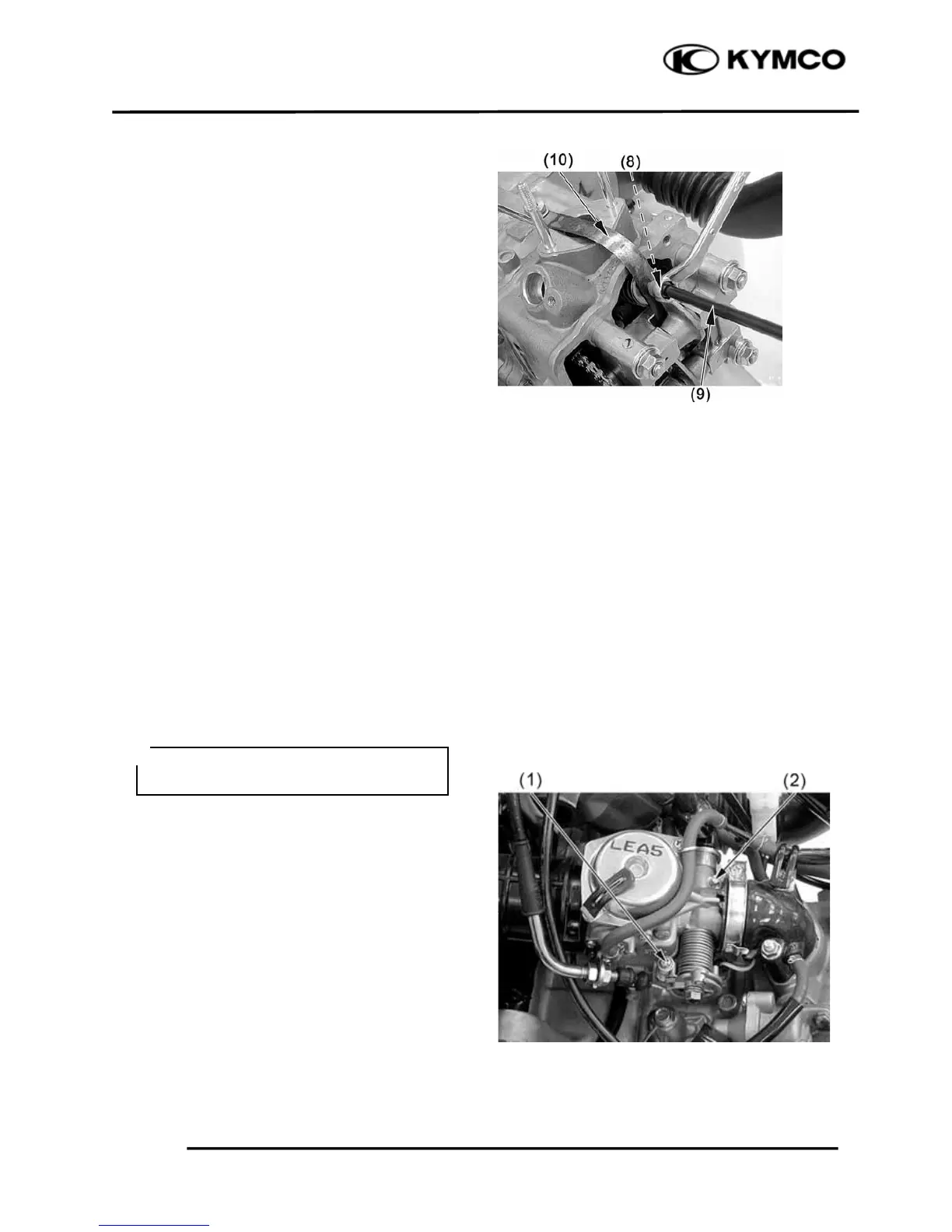

Adjust by loosening the valve adjusting screw

lock-nut (8) and turning the adjusting screw

(9) until there is a slight drag on the thickness

gauge (10).

Valve Clearance: IN: 0.1 mm (0.004 in)

EX: 0.1 mm (0.004 in)

Apply oil to the valve adjusting screw lock-

nut threads and seating surface.

Hold the adjusting screw and tighten the lock

nut to the specified torque.

Torque: 0.9 kgf-m (9 N-m, 6.5 lbf-ft)

Special tool:

Valve adjuster A120E00036

After tightening the lock-nut, recheck the

valve clearance.

Install the removed parts in the reverse order

of removal.

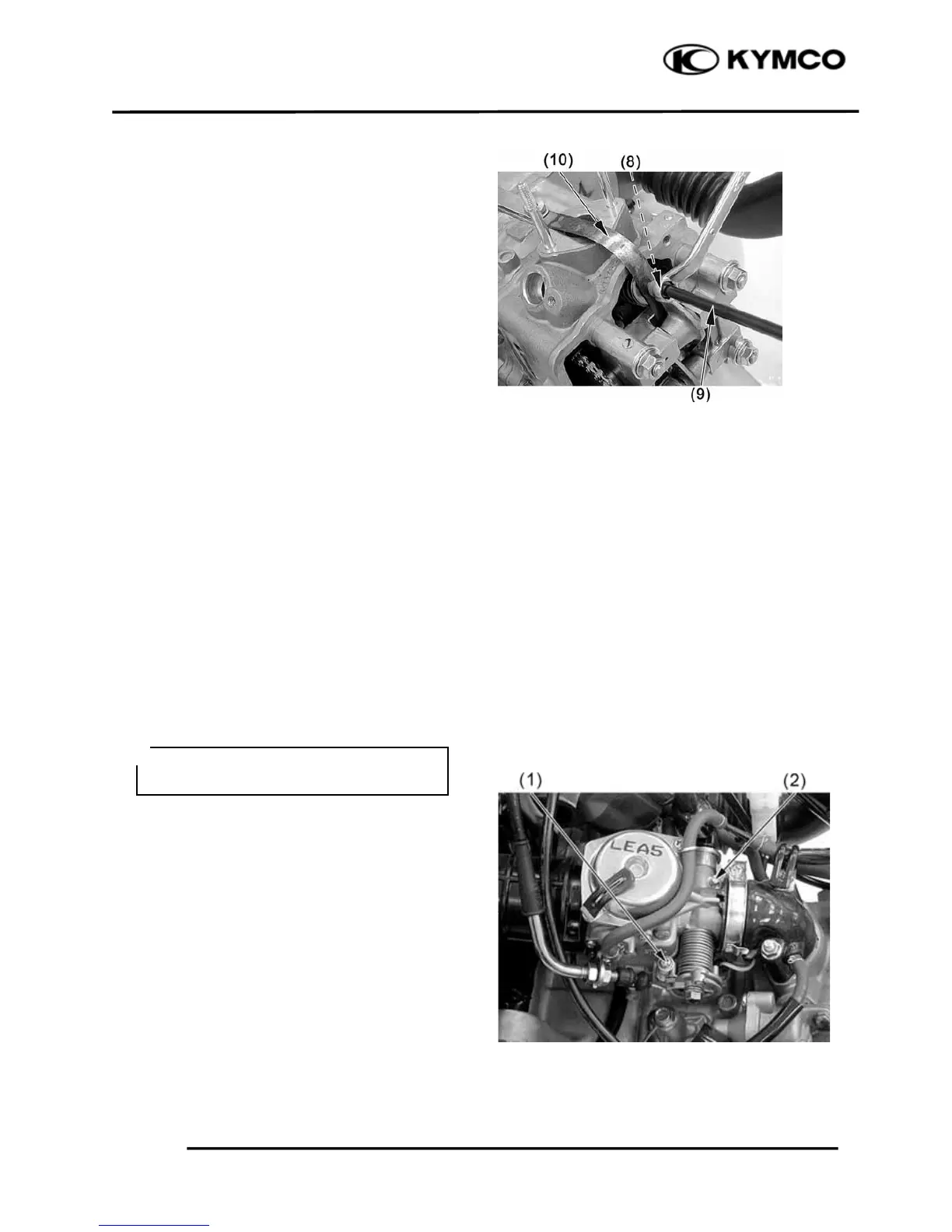

CARBURETOR IDLE SPEED

Warm up the engine before this operation.

Start the engine and connect a tachometer.

Turn the throttle stop screw (1) to obtain the

specified idle speed.

Idle Speed: 1700 rpm—DINK 125

2100±100 rpm—DINK 50

When the engine misses or run erratic, adjust

the pilot screw (2).

IN: 0.1 mm (0.004 in)EX: 0.1 mm (0.004 in)

DINK 125

IN: 0.05mm±0.01mm(0.0016 in~0.0024in)

EX: 0.05mm±0.01mm(0.0016 in~0.0024in)

DINK 50

The engine must be warm for accurate

idle speed inspection and adjustment.

*

(DINK 125))

Loading...

Loading...