6881076C25-E September 5, 2008

Troubleshooting Procedures: Power Amplifier Procedures 4-31

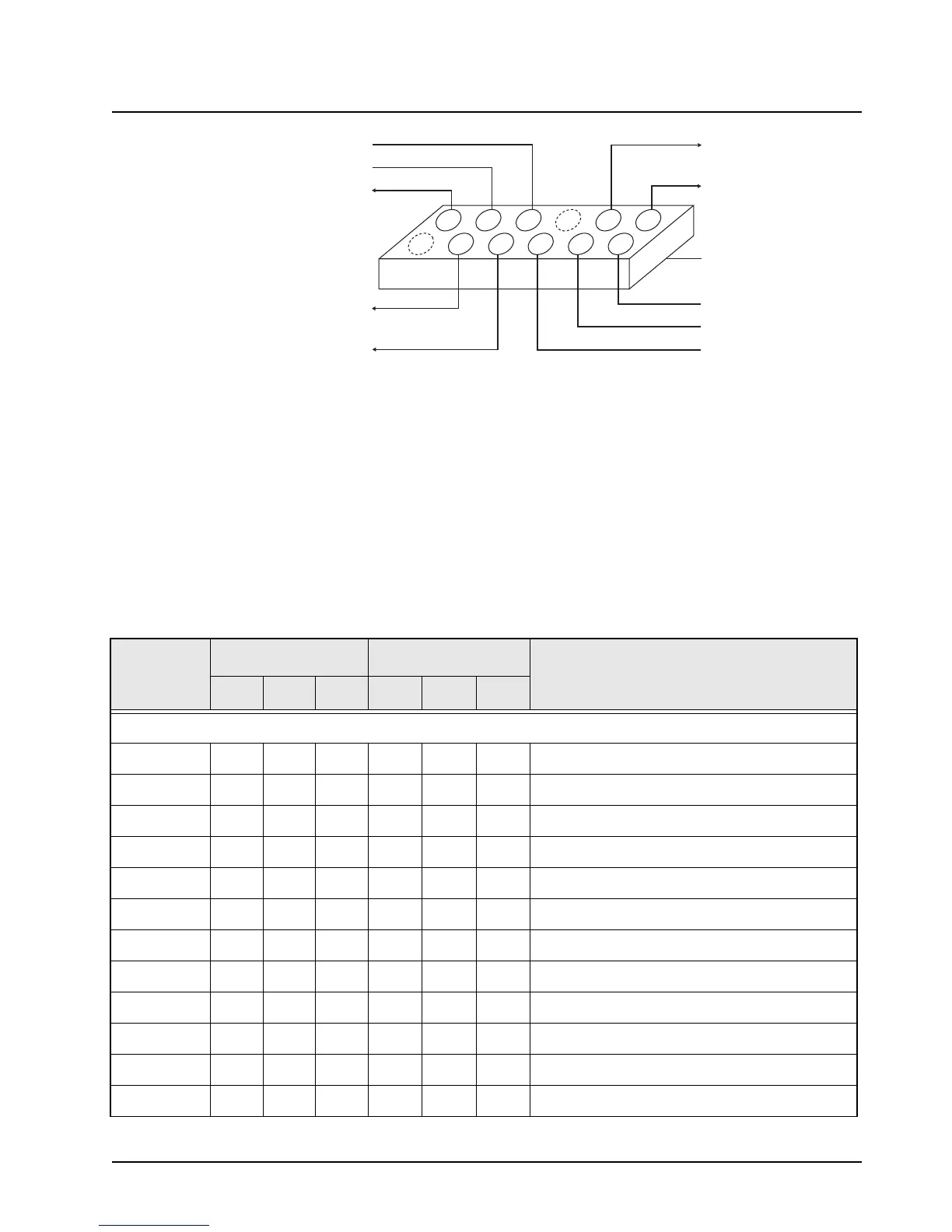

Figure 4-5. PA Test Adapter, 25/10 Watt Power Amplifier

4. With the applied control voltage drive initially at 0 V, slowly increase the voltage until power

out equals 28 Watts. Power should rise smoothly with control voltage once the turn-on

threshold is reached. Control voltage drive should not exceed 9.2 V.

5. If 9.2 V does not produce 28 Watts, then a failure exists in the power amplifier circuit.

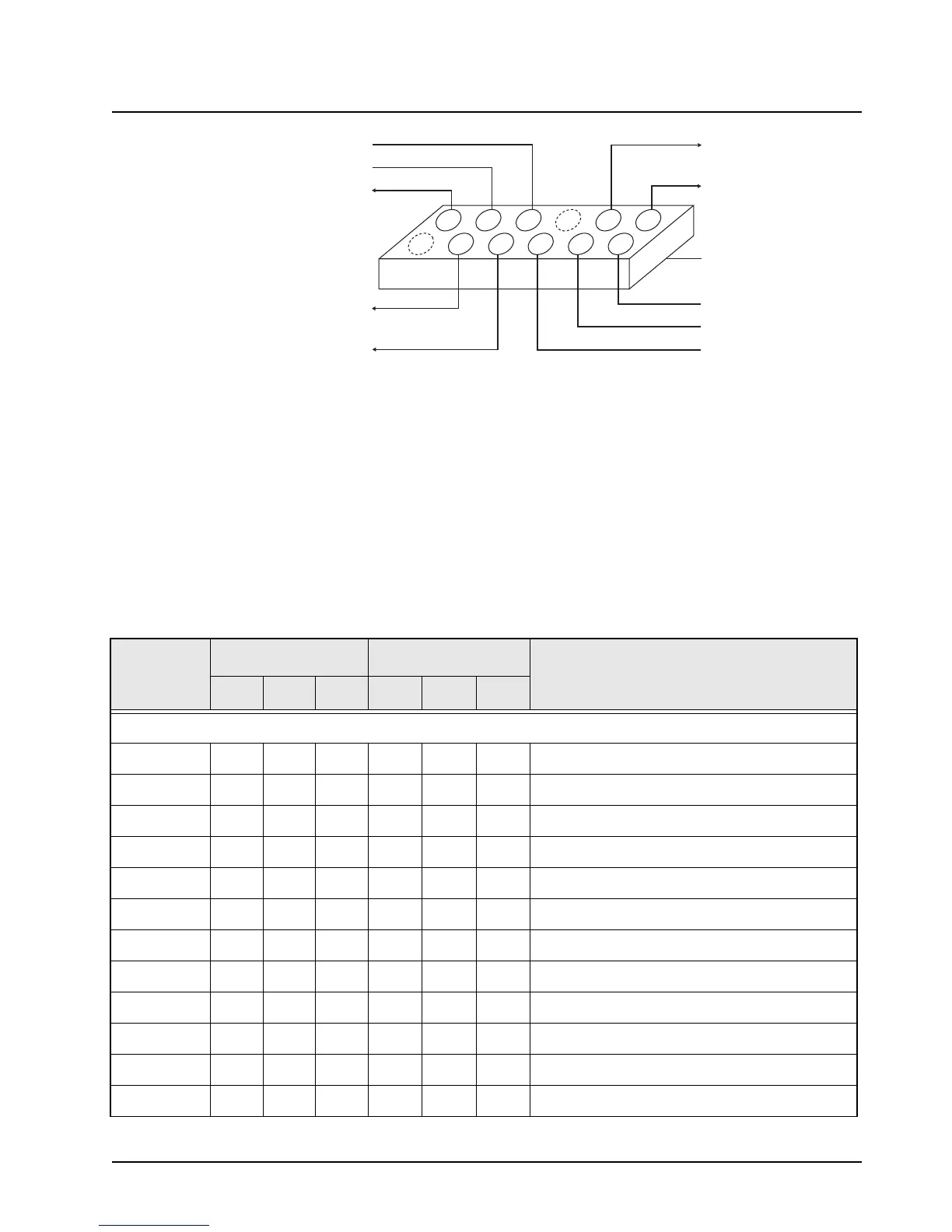

6. Refer to the voltage chart (see Table 4-11). Measure the indicated voltages. If they are not

within the limits shown in the chart, then a failure exists in the PA assembly.

7. If the voltages in the chart are correct, verify that the injection is at least 10 mW. (See the

VCO troubleshooting section.)

8. If no failure is located from the previous checks, troubleshoot the power control circuitry.

Table 4-11. Power Control DC Voltage Chart

LOCATION

RX MODE TX MODE

COMMENTS

LOW TYP HI LOW TYP HI

P0853

1 ––––––

Key (no pin or wire)

2002.03.2

Control Voltage Limit

302.07.09.2

Control Drive Voltage

4 10.8 13.8 16.6 10.4 13.4 16.2

Current Sense +

50009.29.49.8

Keyed 9.4

6 10.8 13.8 16.6 10.4 13.4 16.2

A+ to Command Board

70 1.2

Temp Sense (cutback begins at 3.3 V)

8 ––––––

Key (no pin)

901.53.55.0

Forward Detect Volt

10 10.8 13.8 16.6 10.4 13.4 16.2

A+ to Command Board

11 9.4 9.6 9.9 9.4 9.6 9.9

9.6-V Supply from Command Board

12 10.8 9.8 13.1 15.9

Current Sense – (voltage delta 150 mV)

A+ TO COMMAND BOARD

CURRENT SENSE +

A+ TO COMMAND BOARD

CURRENT SENSE -

CONTROL VOLTAGE LIMIT

CONTROL VOLTAGE DRIVE

K9.4

FEMALE RECEPTACLE

CONNECTOR W 100 MIL

SPACING MATES TO P853

REGULATED 9.6V

V DETECT

TEMP SENSE

8

6

4

2

10

12

7

5

3

1

9

11

Loading...

Loading...