Engine System, Diesel 230Service Manual – CS7000

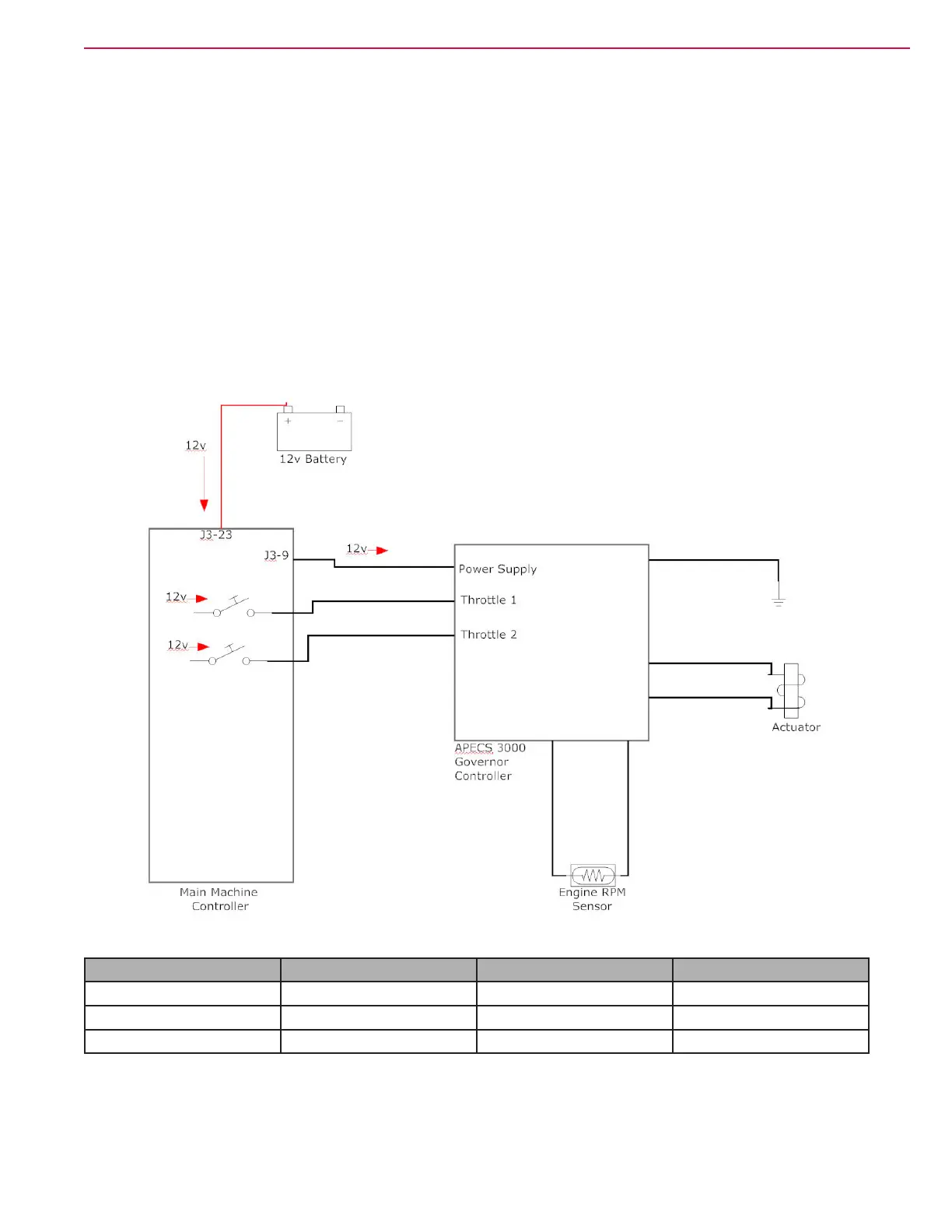

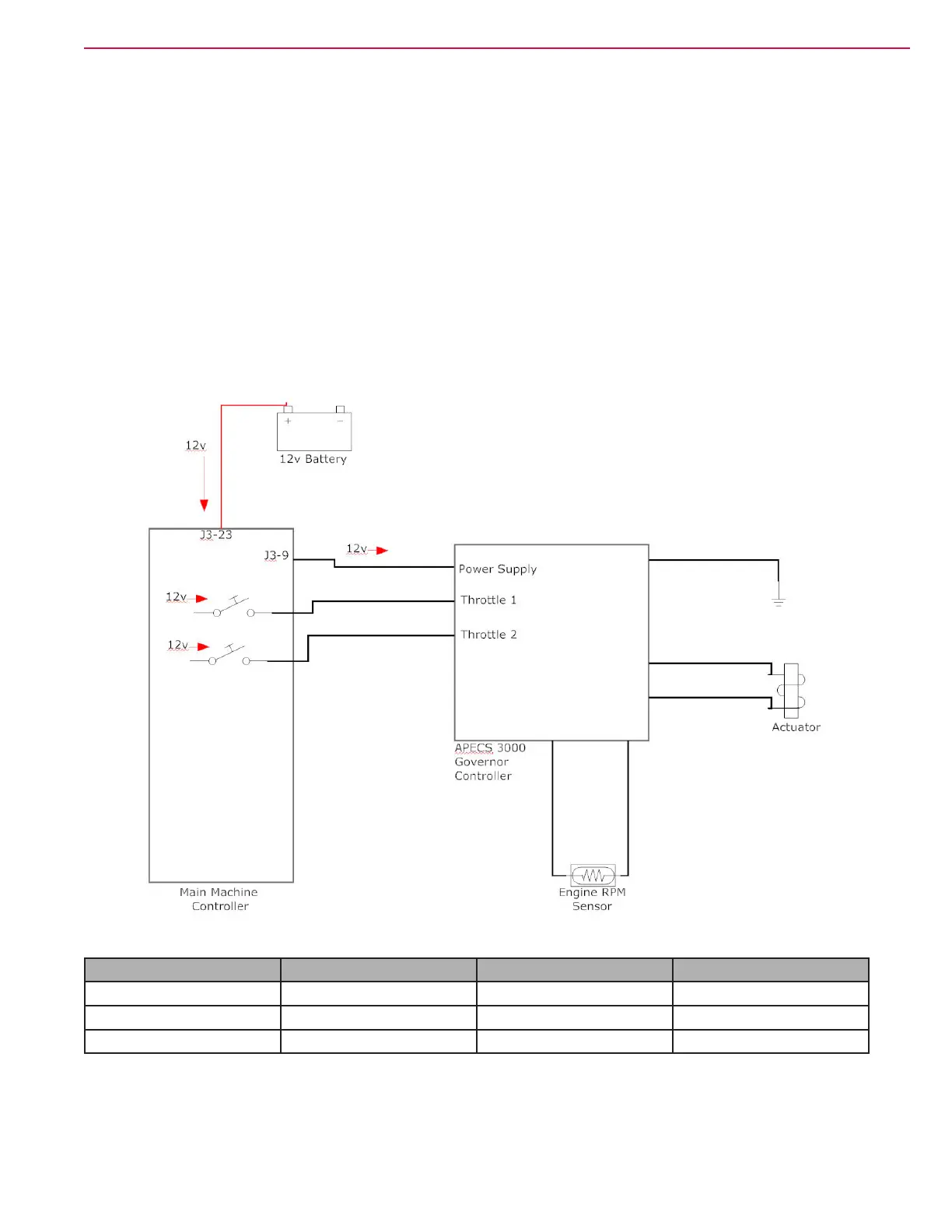

Engine RPM control

The Woodward APECS (Advanced Proportional Engine Control System) controller manages the engine RPM

through the use of an electronic actuator. The controller monitors the actual engine RPM via a speed sensor

which reads the ywheel ring gear teeth and compares it to the desired speed setting. The controller sends

out a pulse width modulated signal to an actuator, which is connected to the engine fuel control lever inside

the injector pump. The actuator is “spring loaded” in the “no fuel” position. This means that by default,

the actuator shuts off the fuel and prevents the engine from running when there is no electrical current

available. When the governor wants to increase the engine speed, it increases the amount of current it sends

through the actuator.

The main machine controller is responsible for telling the governor controller the desired RPM based on

the operator’s request or machine operation mode. It communicates this with two circuits; Throttle 1 and

Throttle 2. To request idle speed it does not apply voltage to either circuit. To request “Run” speed, it sends

out 12 volts on throttle 2 circuit only. To request “maximum power” speed, it sends out 12 volts on throttle 1

circuit only.

Speed Mode Engine Speed Throttle 1 Throttle 2

Idle 1700 RPM 0 0

Run 2200 RPM 0 12v

Maximum Power 2400 RPM 12v 0

Loading...

Loading...