Chapter 3 Functional descriptions

SMSO-2-02.03- 15.07.03 39

3.2.7 Rotary-vane type pump

The pump generates the pressure for all the systems in the

machine. It increases the pressure of the mains water supply

(local mains or fresh water container) to the brewing pressure

required for making coffee (7.5 bar). The pump is thus in op-

eration for every product serving, except steam.

The rotary-vane type pump has a dual effect by-pass system.

the feed bypass and the return bypass. The feed bypass for

this system makes it possible to have input pressure available

on the output side when the pump is at a standstill. The return

bypass has the opposite effect and enables water that is not

required to flow back from the pressurised side (outlet side)

back to the inlet side (input side). This makes it possible to

keep a constant set pressure.

In principle, the pump consists of two main components: the

drive motor and the pump housing with bypass system. These

main components are flanged together and connected by

means of a coupling.

Function

If the pump is not being driven by the motor, water flows

through the bypass system at the pressure of the supply water

mains into the pump outlet side. When the pump is in opera-

tion, the water flows from the inlet into the sliding hatch cham-

ber. The rotor and the sliding hatches convey the water to the

output side. Depending on the water consumption in the ma-

chine the water now flows into the machine with low water

consumption some of it passes back through the by-pass to

the inlet side of the pump.

Pressure setting

The spring-resistance pressing onto the return bypass over

the pistons is adjusted by means of a setting screw. Thereby,

either more or less pressure is built up on the pressure side of

the pump until the bypass valve opens and the excess water

flows back to the inlet side of the pump. The pressure can be

set only if all the outlet valves are closed. During the adjust-

ment process the system must be relieved of pressure at short

intervals by briefly opening a valve, i.e. any excess pressure

that has built up inside the system must be discharged. It is

only thus that the correct pressure will display on the

manometer (see programming instructions, system test

“setting pump pressure.) It must be possible to set the

pressure without making sudden changes.

The effective brewing pressure for preparing coffee depends

on the grinding degree, on the amount of ground coffee (cof-

fee powder), on the compaction pressure and the condition of

the brewing unit. If a pump is repaired or a new pump in-

stalled, the pump pressure must always be reset. If in the

closed system a pressure of 7.5 bar is set, this generally pro-

duces an effective brewing pressure (flow pressure) of around

7.0 bar during coffee preparation.

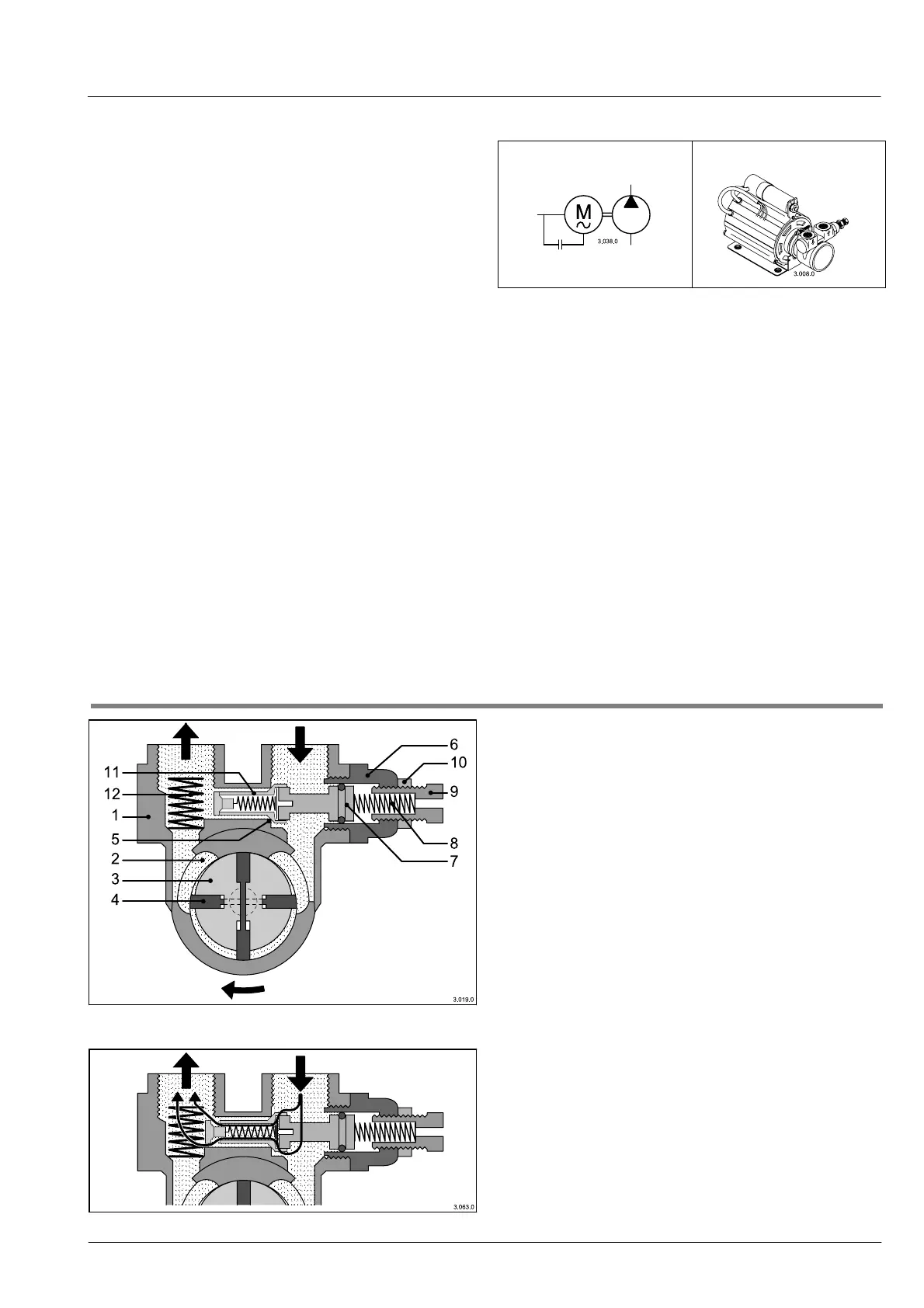

Pump with bypass valve

1 Pump housing

2 Sliding hatch chamber

3 Rotor

4 Sliding hatch

5 Valve seat

6 Bypass housing

7 Piston

8 Adjusting spring

9 Adjusting screw

10 Counter nut

11 By-pass system (feed and return)

12 Coarse filter to by-pass system

Feed bypass: When the pump is at a standstill water flows

to the output side of the pump under the pressure of the

water supply.

Drawing symbol

Illustration

Loading...

Loading...