Chapter 3 Functional descriptions

SMSO-2-02.03- 15.07.03 87

3.4.10 Rinsing the milk – milk foam pipes

(refrigerator with hot water rinse / HOTFLUSH)

02.04.2002 .........

Serial no. 505124 .........

Product serving:

Requirements:

Notes

Previously: No milk or no milk foam has been dispensed for at least thirty minutes. The product servings

are blocked to the rinse cycle

Machine in operation, heated, programmed to serve milk products.

Refrigerator in operation

Hot water from the brewing system is used to rinse the milk and milk foam pipes. In addition, it only

requires a small quantity of steam. Hot water preparation and steam generation are not described in

detail here

(see section "Steam system (milk products)" and brewing system (coffee) with booster"). You can read

the detailed function descriptions of individual components in this chapter under "Components".

The milk and milk foam pipes are always rinsed together during the rinse cycle. Both steam outlet

valves are therefore activated.

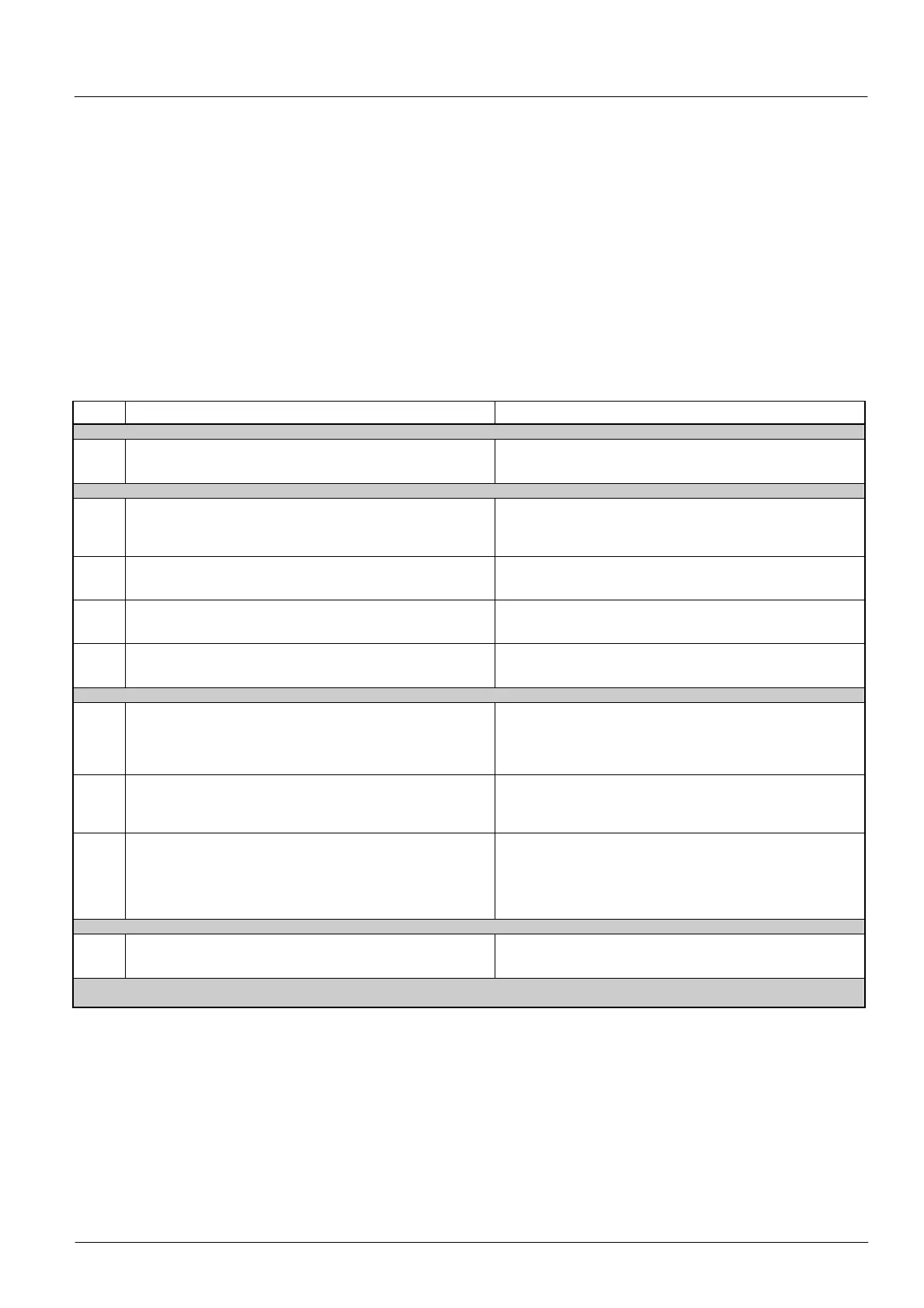

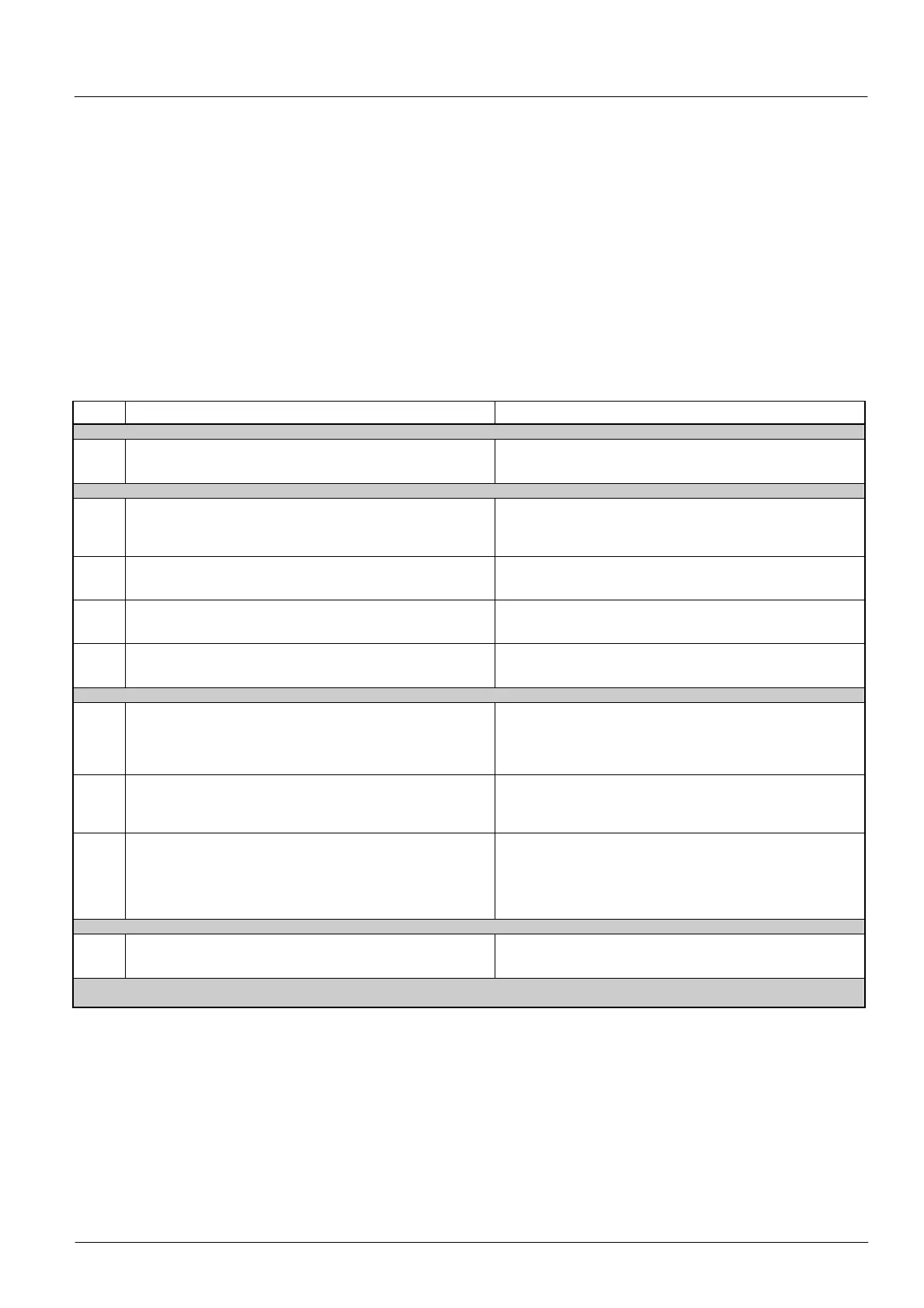

Process

step

Control (electronic/electric) Hydraulic system

Product selection

The monitoring function (timer) of the control unit has indicated

that no milk or milk foam serving has occurred in the past thirty

minutes The milk pipes must be rinsed out.

Squeezing off the milk suction pipes

1 Opening the magnet valve for the water / squeeze cylinder (power

transistor switches through)

Magnet valve opens and water flows into the water cylinder. The

suction pipes for milk and milk foam are squeezed off so that no

rinse water can flow into the milk container.

2 Switching on the rotary-vane type pump The pump creates the pressure in the water system and keeps it

constant.

Cold water can flow back to the instant heater.

Opening the magnet valve on the instant heater (power transistor

switches through)

Magnet valve opens. Hot water flows to the non-return valve of the

refrigerator. The milk and milk foam pipe are rinsed with water.

The rinse water flows into the drip tray.

After the set time, the control unit switches the magnet valve off.

The water rinse is finished.

The rotary-vane type pump is switched off.

The rotary-vane type pump is shut down and the pressure in the

system falls to the "local pressure".

Sucking out the milk pipes and rinsing the foamer head

3 Opening the steam outlet valves for milk and milk foam (power

transistors switch through)

The magnet valves open and the steam flows through the injector

nozzles to the foamer head. Due to the under-pressure of the

injector nozzles, the content of the milk or milk foam pipe is suc-

tioned in from the refrigerator. The rinse water flows into the drip

tray.

4 The magnet valve switches off for the water / squeeze cylinder Magnet valve closes; Water/squeeze cylinder releases milk suc-

tion pipes and the milk can now be suctioned in. The water lo-

cated in the water/squeeze cylinder flows out through the relief

hose.

5

After approx. 0.2 seconds:

Activation of the lift magnet of the ventilation valve (power transis-

tor switches through)

The lift magnet opens the ventilation valve. The pipes to the

foamer head are suctioned out until empty by escaping steam

from the injector nozzles. The milk foamer housing is rinsed out.

The rinse water flows into the drip tray.

The milk suctioned for short time up to the ventilation valve flows

back to the milk container.

Ending the rinsing cycle

6 Switching off the magnetic valves and the lift magnet The steam output is ended; the milk or milk foam pipes and the

milk foamer header are rinsed and suctioned until empty.

The ventilation valve closes the milk and milk foam pipes.

Heating up the instant heater, see "Brewing System (Coffee) with Booster".

Heating up the steam generator, filling up the steam generator see "Steam System" (Milk Products)"

Loading...

Loading...