Chapter 3 Functional descriptions

SMSO-2-02.03- 15.07.03 73

3.4.3 Brewing system (coffee) with booster 02.04.2002 .........

Serial no. 505124 .........

Product serving:

Requirements:

A cup of espresso coffee

Coffee machine in operation, heated, programmed to produce an espresso with prebrewing.

Notes

Some processes are shown in simplified form in the following description. See the section entitled

“components” in the chapter entitled “Functional descriptions, components) for detailed functional de-

scriptions of individual components (e.g. pump with bypass, flowmeter etc).

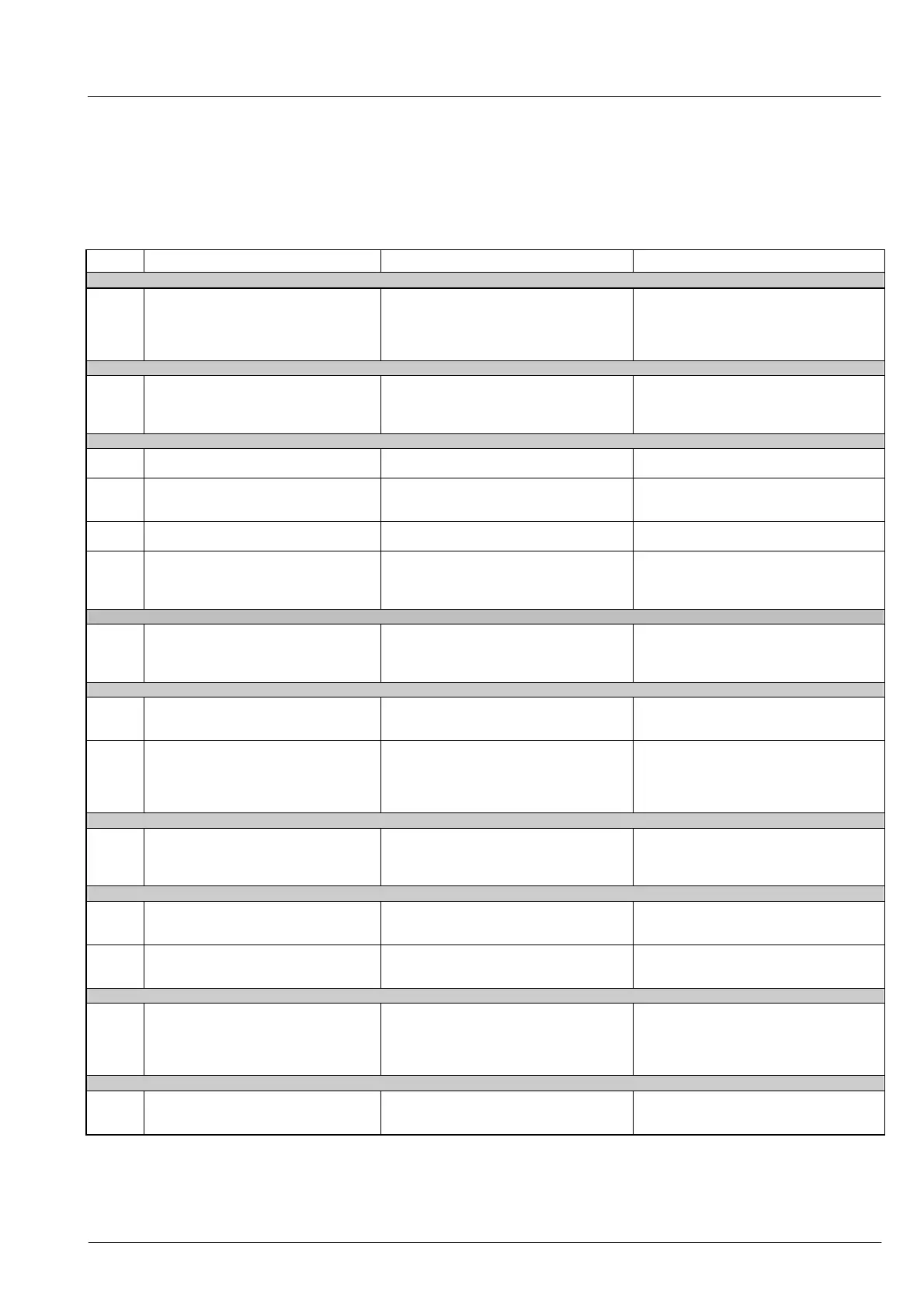

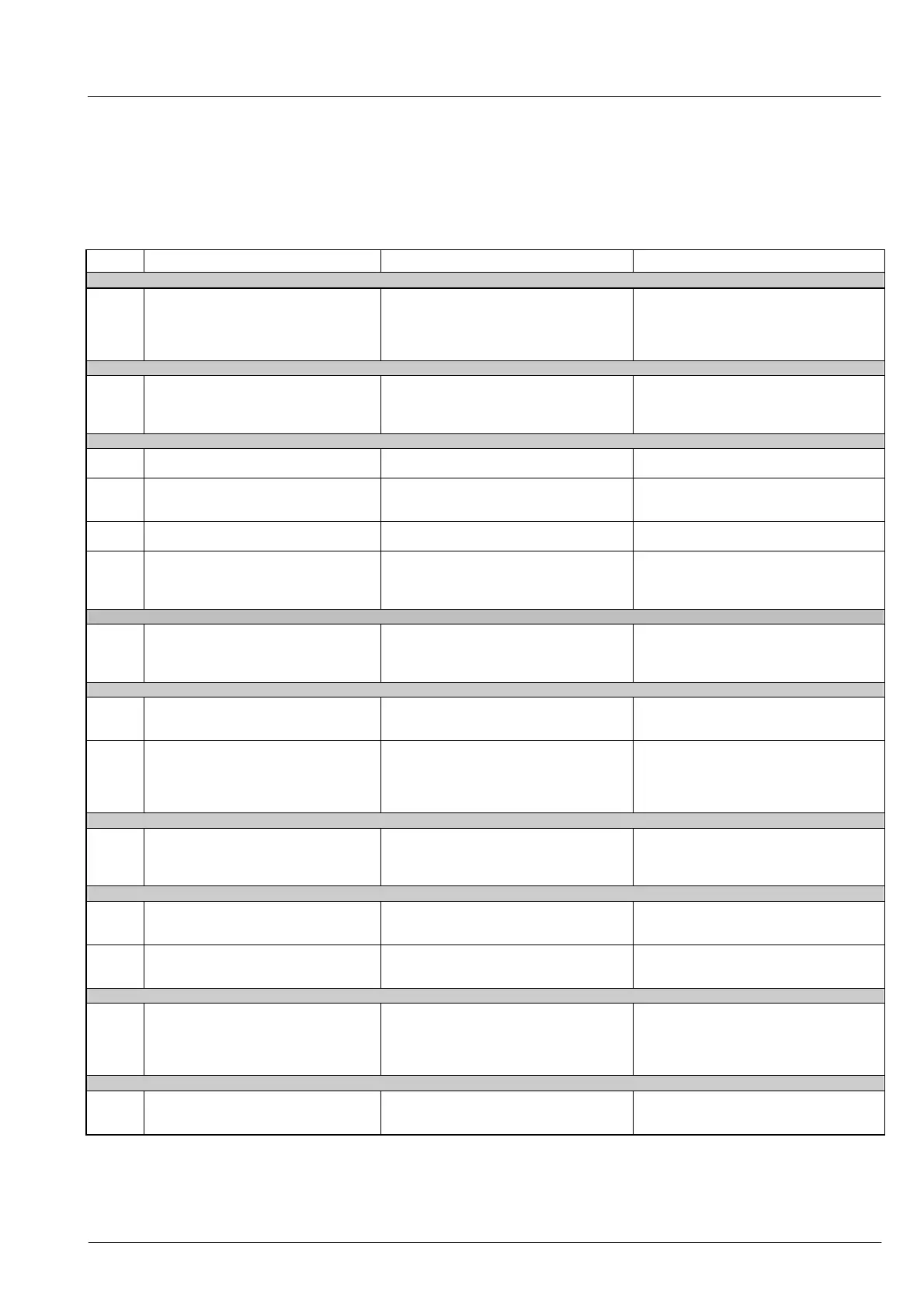

Process

step

Control system (electronic/electrical) Hydraulic system Mechanical processes

Product selection

1 The “espresso” button is pressed.

The signal from the button panel reaches

the unit control system; the program

analyses the command and starts the

product preparation cycle.

Grind coffee

2 Grinder motor switches on: The power

transistor connects through; the grinder

motor goes into operation for the set

number of units (approx. 4.5 seconds).

Grinder operates, freshly ground coffee falls

through the powder chute into the brewing

cylinder of the brewing unit.

Close brewing unit, pressure increases

3 Piston motor switches on: Power transis-

tor connects through

The brewing cylinder moves upwards and

compresses the ground coffee.

As soon as the compaction pressure has

been reached, the piston motor is

switched off due to the current measured.

4 Rotary vane pump switches on; relay

connects.

Pump produces the pressure in the water

system and holds it constant.

5 Brewing valve opens, power transistor

connects through.

The brewing valve opens, hot water flows

from the instant heater into the booster, is

further heated there, and then moves into

the brewing cylinder.

Prebrewing / water metering

After the number of pulses set for the

prebrewing process, the brewing valve is

closed for the programmed prebrewing

period and then reopened.

The water flow into the brewing cylinder is

interrupted briefly.

After the prebrewing process, coffee flows

into the cup.

Brewing process

6 The water metering process is activated

The flowmeter supplies the amount of water

in accordance with the pulses for the quan-

tity dosing.

7 The brewing process ends once the pro-

grammed water quantity has been dis-

pensed. Brewing valve closes and at the

same time opens the discharge way. The

rotary vane type pump is switched off.

Brewing valve closes, hot water inlet to

brewing unit stops. Discharge way opens

and the pump stops. The pressure in the

system falls to “local pressure”.

Heating the instant heater

8 The instant heater heating is switched on

and off according to the programmed

control conditions (transistor switches

power relay 11)

The water in the instant heater is heated.

Repress

9 Switch on piston motor to repress the

coffee grounds. The piston motor stays on

for approximately 0.2 seconds.

The brewing cylinder travels upwards a little

higher and presses the remaining water out

of the coffee grounds

The remaining water in the coffee grounds

flows through the brewing pipe and the

discharge way into the drain funnel.

Ejection of coffee grounds, brewing unit moves back to the start position

10 End re-press process, reverse the direc-

tion of the piston motor to open the brew-

ing cylinder. Right at the bottom, the

direction of rotation is reversed based on

the measured current.

Brewing cylinder now travels down. The

wiper ejects the coffee grounds from the

brewing cylinder into the drawer for coffee

grounds. The brewing cylinder moves back

to the start position

Start position of brewing unit

11 The microswitch sends a “start position

reached” signal; the piston motor switches

off

The brewing unit is in the start position.

Additional water

To made a weak coffee (for example so that a spirit can be added) there is a bypass system that is used for a programmed

period, while the product is discharged (step 6) to mix hot water from the instant heater through the bypass valve into the coffee

outlet pipe.

Loading...

Loading...