Chapter 3 Functional descriptions

SMSO-2-02.03- 15.07.03 79

3.4.6 Steam system (milk drinks)

Product serving:

Requirements:

Notes

To heat a cup of milk and then to cause it to foam.

Machine in operation, heated up, programmed to automatically serve steam.

Some processes are shown in simplified form in the following description. See the section entitled

“components” in this chapter for detailed functional descriptions of individual components (e.g. pump

with bypass).

Water metering:

The water quantity can be metered in two ways:

Time controlled by the programming system

By programming the start and stop operation: the hot water starts to flow out when the button is

pressed for the first time, and it stops when pressed a second time. (Timeout: If the button is not

pressed a second time after a certain period of time, the hot water automatically stops running out.

The sequence of the individual steps of “steam outlet”, “heating the steam generator”, “end of

steam outlet” and “feeding the steam generator” may vary slightly depending on the amount of

steam drawn.

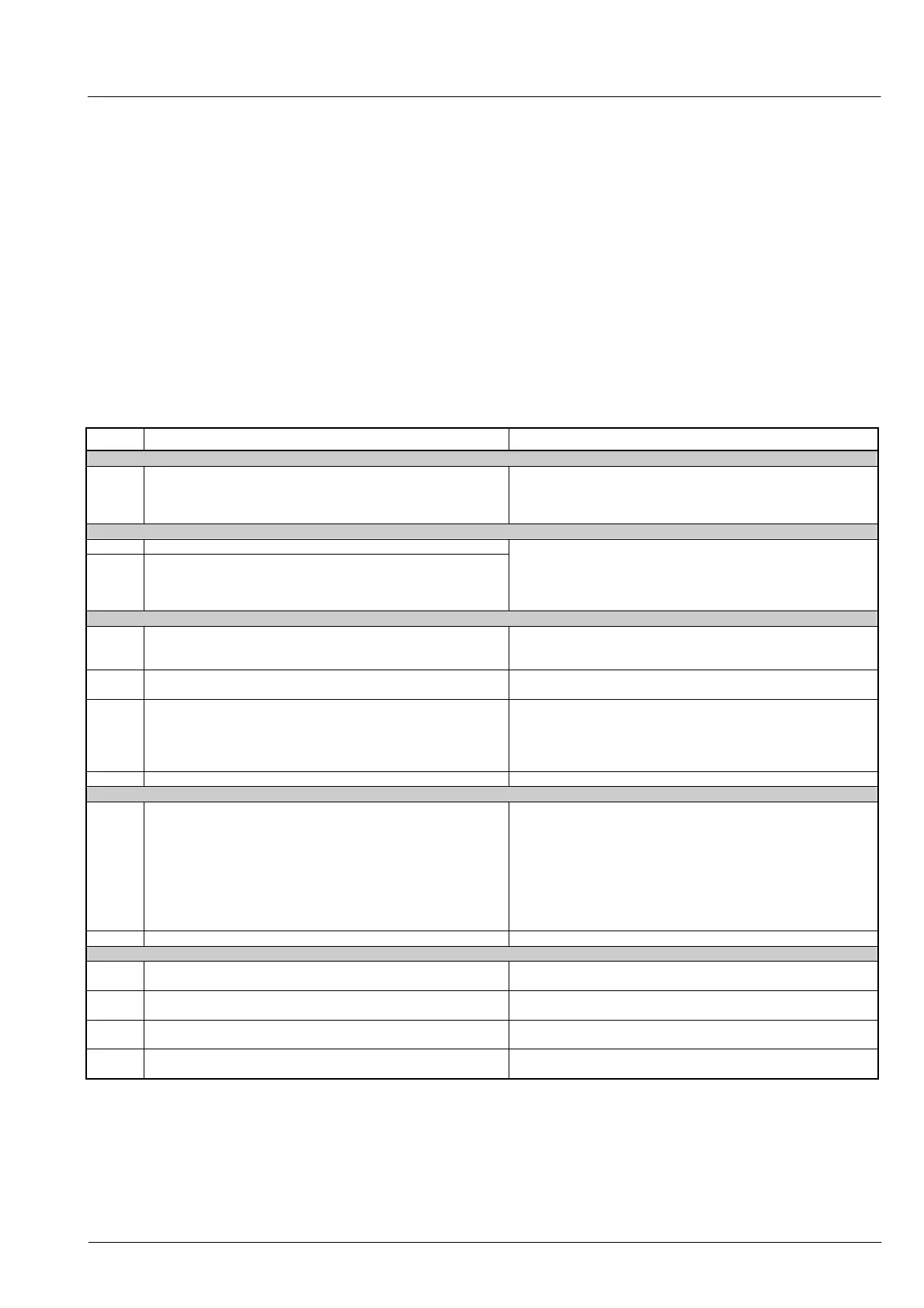

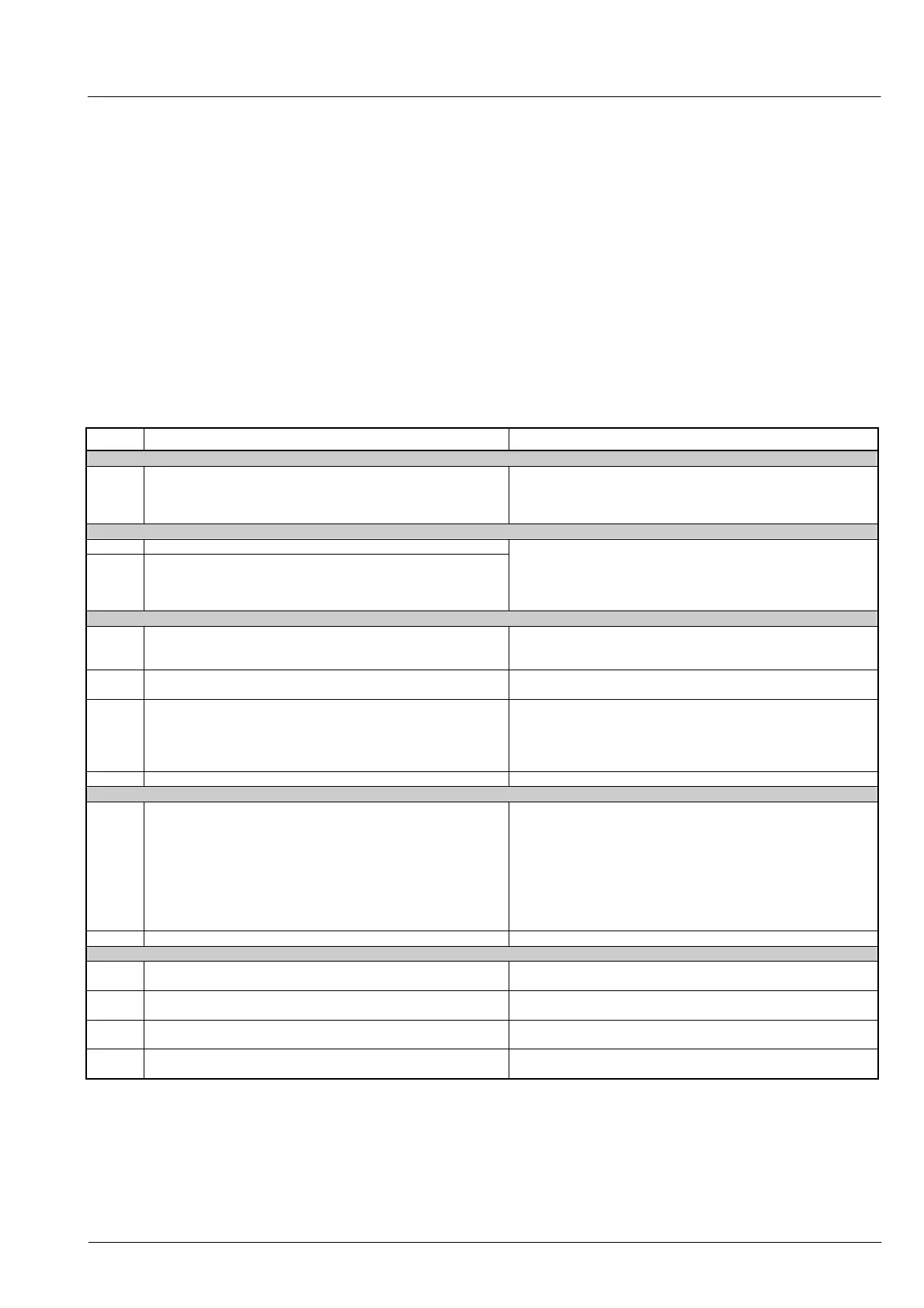

Process

step

Control system (electronic/electrical) Hydraulic system

Product selection

1 The “steam” button is pressed.

The signal from the button panel reaches the unit control system;

the program analyses the command and starts the steam outlet

operation.

Steam outlet operation

2 Steam outlet valve opens, (power transistor connects through).

The solenoid valve opens and steam flows to the steam nozzle.

The milk is heated and foamed. The pressure in the steam gen-

erator reduces and water continues to evaporate. In this way the

temperature decreases and the water level in the steam generator

goes down.

Heat the steam generator

3 The temperature in the steam generator falls; change in resis-

tance in the temperature sensor sends a “heat” signal to the con-

trol system.

4 Heating for steam generator switches on (relay 9 connects the

load relay).

5 Water in the steam generator is heated and evaporates into

steam. The water level continues to fall. Once the steam tempera-

ture is reached (approximately 130

o

C) the change in resistance

in the temperature sensor sends a “switch off heater” signal to the

control system.

Heater switches off (relay 9 switches off load relay).

End of steam outlet

6 The milk drink is heated up and foamed.

For programmed quantities of steam, the steam outlet valve

is closed after the period for dispensing the product has ex-

pired.

With programmed start-stop operation:

The “steam” button is pressed again; the signal from the but-

ton panel reaches the unit control system; the program analy-

ses the control command and stops the product from

dispensing. The steam outlet valve closes.

The solenoid valve closes and the steam outlet procedure ends

Top up the steam generator

7 The tip of the level probe is no longer immersed in water and

sends a “top up water level” signal to the control system.

Rotary vane type pump switches on (relay 3 connects) and feed

valve on distributor block opens (transistor connects through).

The pump produces the pressure in the water system and holds it

constant. Water flows into the steam generator to top it up.

8 The water level is reached, the level probe sends a “level

reached” signal to the control system.

The rotary vane type pump switches off and the feed valve on the

distributor block closes

Loading...

Loading...