Chapter 3 Functional descriptions

44 SMSO-2-02.03- 15.07.03

3.2.10 Safety valve

The safety valve is a stop valve where on the input side there

is pressure and on the output side there is no pressure. Safety

valves form part of a multi-level safety concept to protect the

instant heater and steam generator from overheating and from

bursting under over-pressure. The safety valves are fitted

either into the supply pipe or into the hot water / steam pipe for

the instant heater / steam generator. Overpressure caused by

water expansion is diverted into the drip tray. This type of

valve can be fitted to any position because the spring always

keeps the closing element on the valve seat.

Function

The closing element is pressed onto the valve seat by means

of spring-resistance. If the water pressure on the inlet side

exceeds the closing pressure of the spring, the valve opens

and water flows through. Since overpressure can never occur

on the outlet side, the opening pressure is dependent on the

spring-resistance only. Safety valves must never be disman-

tled and their springs must never be replaced. Screw connec-

tions on the safety valve housing are coated with lead seal

coating, which would be broken if the valve were dismantled.

Special feature Take note of the direction of installation

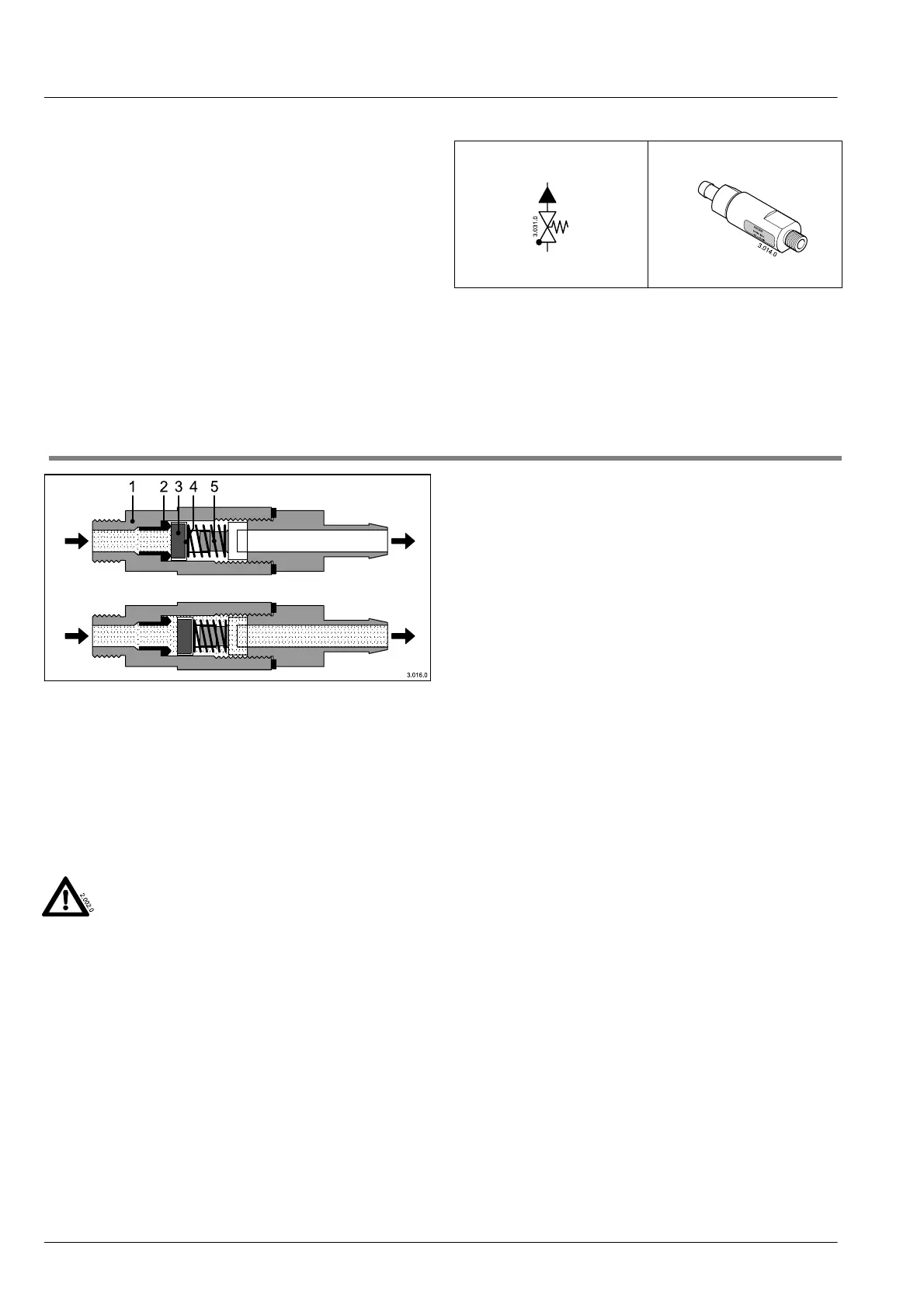

Pressure relief valve

1 Housing (in two parts, screw connection)

2 Valve seat

3 Flat packing in closing element

4 Closing element

5 Pressure spring (depending on opening pressure)

DANGER TO LIFE / MATERIAL DAMAGE

Safety valves can only comply with

their safety functions if they are in-

stalled in the correct direction of flow.

Incorrectly installed valves can cause

the pressure to rise too high and the in-

stant heater or steam generator to

burst. Life-threatening injuries and ma-

terial damage could occur. When

installing a safety valve make sure that

it is installed in the correct direction.

Safety valves must not be disassem-

bled, decalcified and reassembled.

Do not use valves with damaged lead

seal coating .

Technical data

Opening pressure: Nominal: 11 bar

Maximum: 12 bar

Maintenance

Most frequent faults

Calcium deposits or soiling: continual flow of water as a

result of calcium or dirt particles on the flat packing or on

the valve seat.

Pressure spring fatigue: The opening pressure decreases

under a brewing pressure of 7.5 bar thus causing

incorrect dosing (insufficient quantity of product

dispensed).

Check

Service technicians must not open safety valves. If you sus-

pect that such a valve is malfunctioning (traces of calcium

etc.) or if a safety thermostat is triggered, the safety valve

must be replaced.

Service intervals

After 45,000 coffees or after 12 months operation, or if a

safety thermostat triggers, replace the following:

the complete safety valve

Drawing symbol Illustration

Loading...

Loading...