Chapter 3 Functional descriptions

64 SMSO-2-02.03- 15.07.03

3.3 Refrigerator (optional feature)

The refrigerator option consists of a small refrigerator in which

milk is kept and the dosing and cleaning unit for the serving of

milk. The milk can be served as a product on its own (hot

milk). However, it is also possible to serve milk foam to sup-

plement other products from the coffee machine (such as

cappuccinos for example). The refrigerator is fully integrated

into the coffee machine as regards the control system and

accounting. It therefore does not require separate control

components, or separate supply or disposal elements.

Function

General

As a natural product milk is a very awkward product to handle

in dosing and filling systems. The various dynamic character-

istics (viscosity) caused by its fat content , its temperature and

its storage time in “semi-opened” containers makes extremely

high demands on the technical equipment and on hygiene

measures. In unfavourable conditions (such as temperatures

over 5

o

C, open air infeed, unsuitable container material) milk

has a rapid tendency to ferment (i.e. coagulate into a cheese-

like mass). This coagulated mass will very quickly be covered

in mildew if the unfavourable conditions continue.

By selecting suitable materials and using simply shapes for

the dosing and outlet components suitable for pouring liquids,

these disadvantages can be eliminated to a degree. However,

the design is of use only when the system is operated in con-

ditions of absolute hygiene.

The main components of the refrigerator are the insulated

cabinet housing with the integral evaporator and temperature

sensor. The compressor is located on the cabinet, together

with the cooling unit and the ventilator.

A refrigerant with a low evaporation point circulates within the

closed cooling system. The compressor extracts refrigerant

from the evaporator; under-pressure occurs in the evaporator.

The cooling system and capillary tube are located between the

compressor and the evaporator. These place a considerable

resistance against the flow of refrigerant. The temperature of

the refrigerant is raised to approximately 120

o

C by compres-

sion. The heat is dissipated to the ambient air inside the cool-

ing unit (heat exchanger) and the refrigerant condenses (be-

comes fluid). A ventilator ensures that there is sufficient air

flow for the cooling operation.

The refrigerant flows into the filter drier at the end of the capil-

lary tube. Here it is filtered and any residual moisture is fixed.

It reaches the evaporator from the filter drier. Due to the un-

der-pressure that is in effect here, and the larger cross-section

of pipe (volume) the refrigerant can expand; it evaporates. The

necessary evaporation heat is thus drawn from the refriger-

ated product inside the refrigerator (i.e. from the milk). Once it

has flowed through the evaporator, the refrigerant goes back

to the compressor. The refrigerant circuit is thus closed. The

temperature is controlled by a thermostat that measures the

temperature of the cooling area.

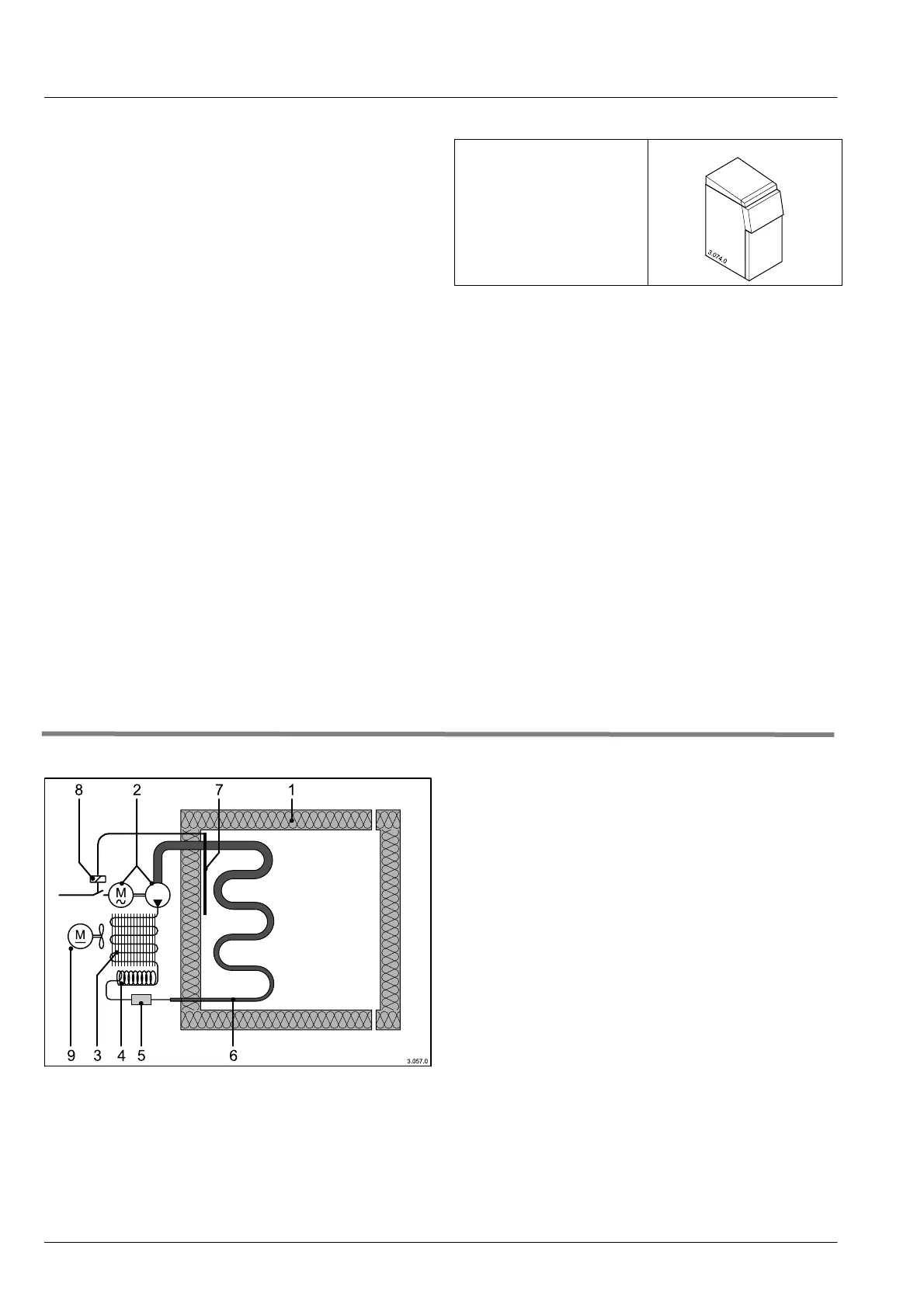

Refrigerator

1 Housing

2 Compressor (with motor)

3 Cooling unit (heat exchanger)

4 Capillary tube

5 Evaporator

6 Temperature sensor

7 Switch-on relay

8 Ventilator

Drawing symbol

Illustration

Loading...

Loading...