Chapter 4 Fault diagnosis

90 SMSO-2-02.03- 15.07.03

4.1.4 Fault lists

The fault lists are structured as follows:

system / component

possible cause

remedy

In the remedy column, you will generally find a reference to

the relevant section of the chapters on “Maintenance”, “Con-

trol system diagram”, and “Spare parts list”..

The sequence of the description of the fault is system-specific.

In hydraulic systems, it is in the order of the flow of water,

i.e. from the water connection to the discharge point of

the product concerned.

In electrical systems, it is in the order of the direction of

current (signal flow).

For program errors, it is in the sequence of operator

guidance.

In this way all the components are included systematically into

consideration and thoughts regarding the location of the fault.

We recommend, particularly to less experienced service tech-

nicians, that when locating a fault, you systematically check a

sub-system of a machine from the very beginning. This is

important because often several faults together can cause a

malfunction.

The most frequent faults have a grey background.

The first part lists all the faults that are displayed as fault mes-

sages on the display, and where, according to the user man-

ual, a service technician needs to be called if the customer

cannot rectify the fault himself.

Understanding of the system

All the systems are explained in compact form, together with

their mechanical, hydraulic and program functions, in the sec-

tion entitled “Functional descriptions, system descriptions.

4.1.5 Grades of fault

The coffee machine has a comprehensive programmed auto-

diagnosis system and monitoring functions to assist in fault

location. This interactive help makes the search for faults

considerably easier. A requirement for it to operate correctly is

that the program is functioning perfectly, and all the conditions

are met to enable the program to run.

From this, it follows that not all errors and faults are equally

serious. There are, as it were, more serious errors and faults

and these defects can be differentiated in principle into three

grades of weighting. These three grades are independent of

one another.

The first grade is made up of the straightforward, passive

components and basic functions: They are not monitored

and a defect is not indicated anywhere. Intervention can

take place independently of the functioning of the other

grades. A service technician must detect such first grade

defects having made plausible checks and tests.

The second grade is formed by all the elements of which

the functions are monitored. Their function depends on

the ability of the program to function reliably. Fault

statuses are detected and indicated on the display panel.

Specific corrective action can then be taken.

The third grade of fault is formed by the control system

(program). The program cannot sufficiently monitor itself.

A partial malfunction in the program is correspondingly

difficult to diagnose. You should ensure that the complete

interactive section of the machine consists of a number of

ICs as well as the display and the input elements. It is

also correspondingly difficult to reproduce the interactive

part of the machine.

The following consequences result from the three grades of

fault weighting as stated, especially if certain events affect

components from all three grades of fault.

The “sequence of repair” goes from level 3 to level 1.

In practical terms this means:

First the program and the input/output elements must be

functioning correctly.

At this point, the elements from the second grade are

being monitored and these diagnostic functions provide

information regarding the repair of elements in this grade.

Finally faults in the first grade can be located more easily

on the basis of the third and second grades that are now

functioning correctly. These faults are generally of a

purely mechanical nature.

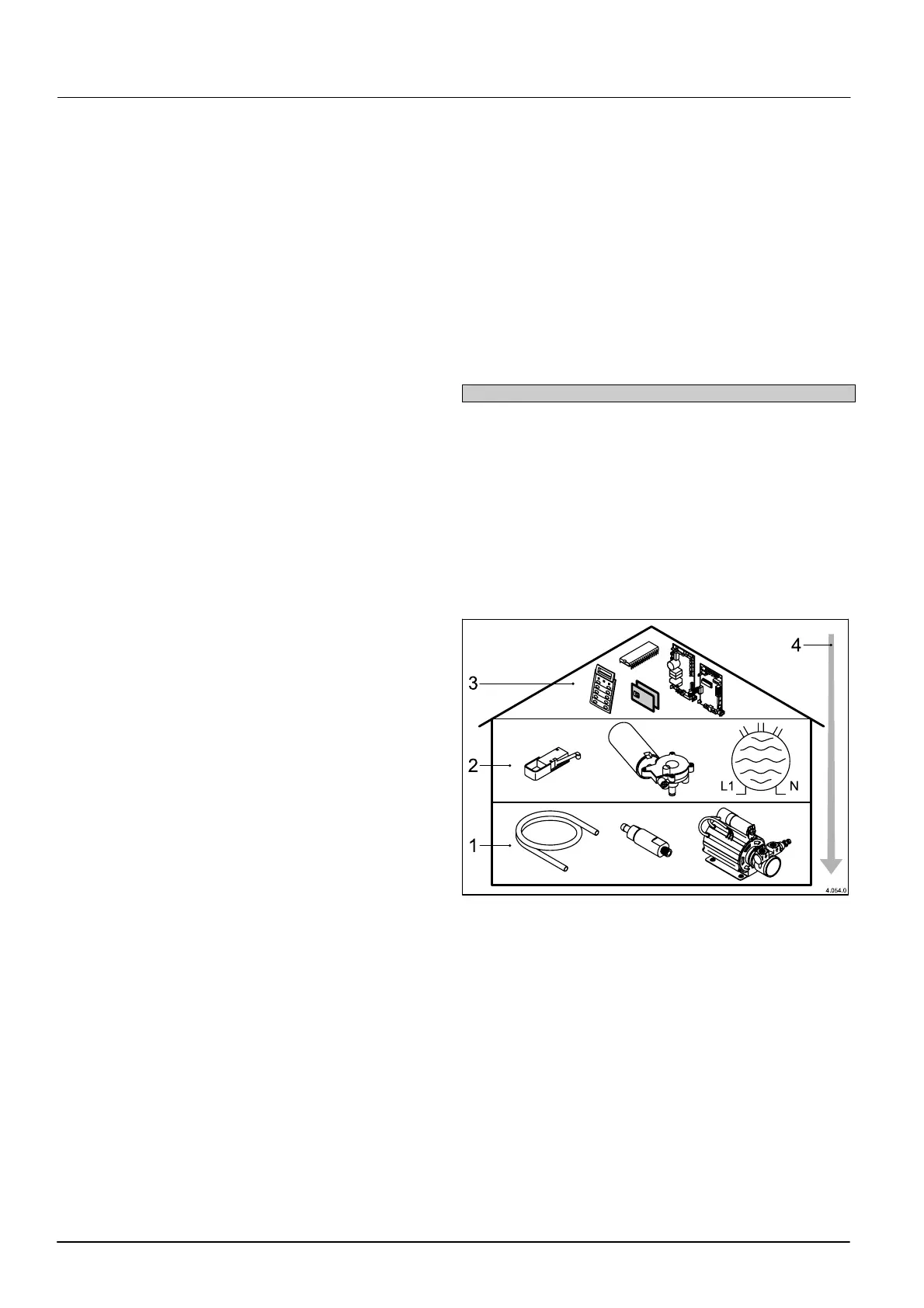

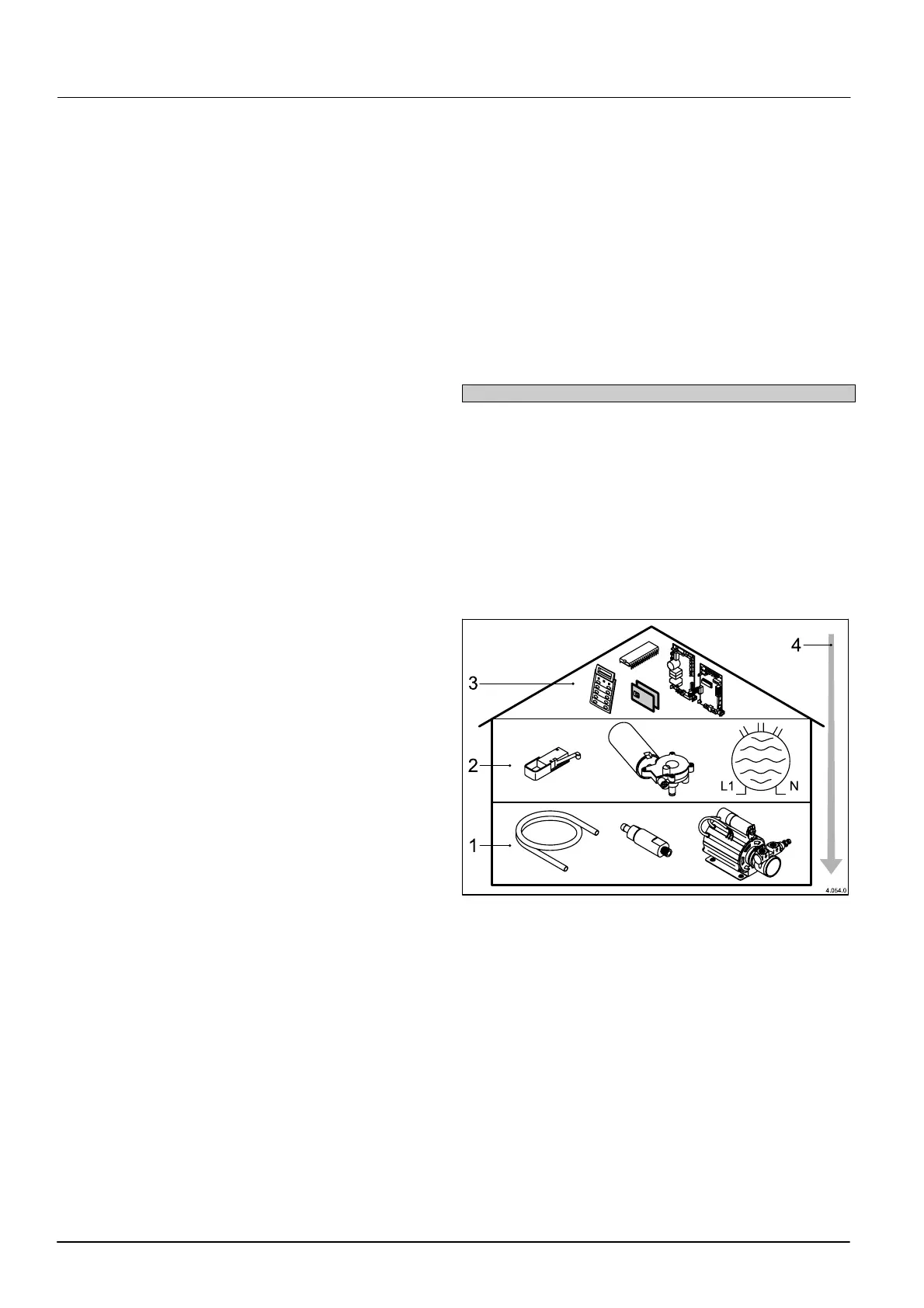

The three grades of faults

1. Basic faults (passive components such as the safety

valve, pump, pipes)

2 Monitored functions (active components) such as heater,

piston motor, limit switch

3 Interactive elements such as the program, chip cards, unit

control system etc.

4 Direction of repair (from grade three to grade one)

Loading...

Loading...