1C-5 Engine Electrical Devices:

Installation

Install the ECT sensor in the reverse order of removal.

Pay attention to the following points:

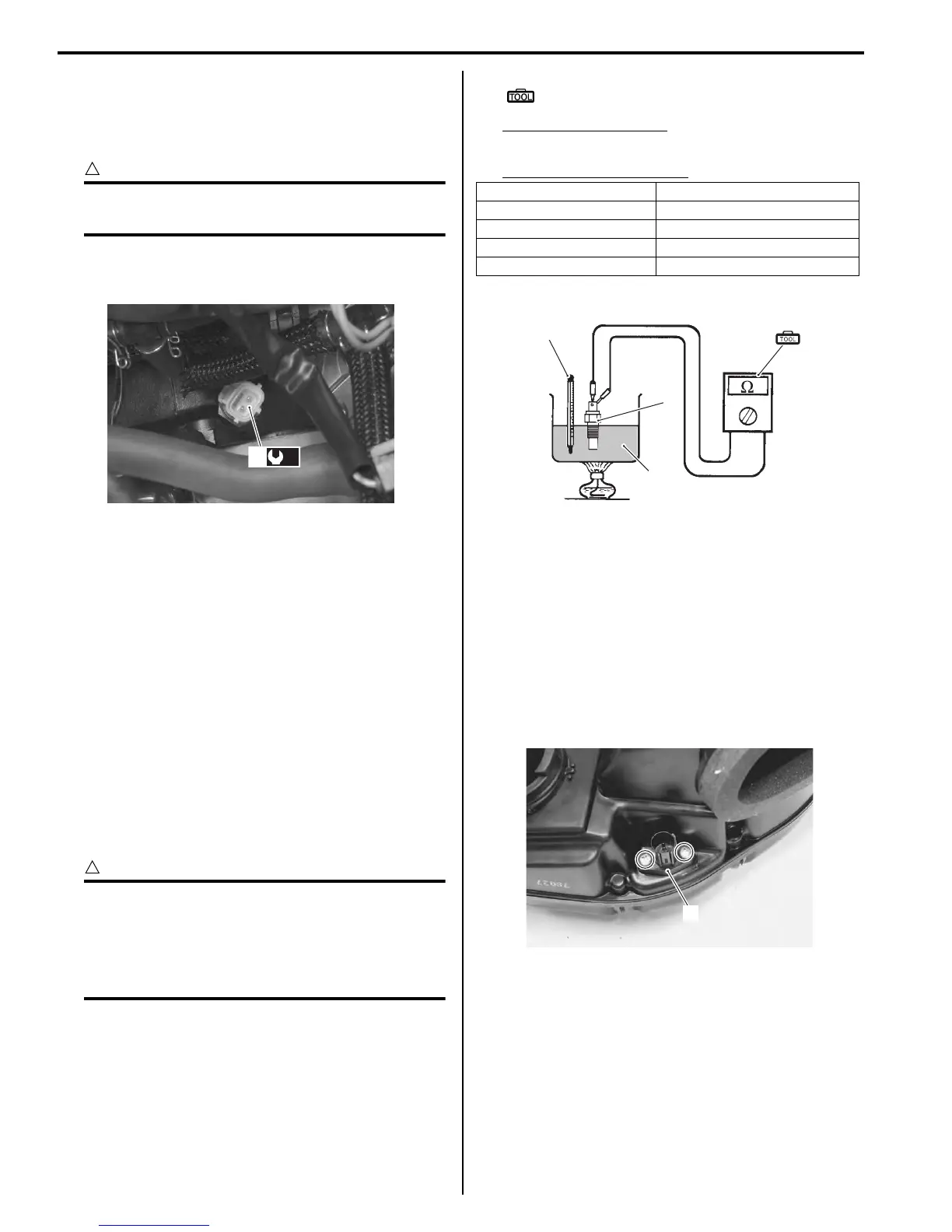

• Tighten the ECT sensor (1) to the specified torque.

CAUTION

!

Use new gasket washer to prevent engine

coolant leakage.

Tightening torque

ECT sensor (a): 18 N·m (1.8 kgf-m, 13.0 lb-ft)

• Pour engine coolant. Refer to “Cooling System

Inspection in Section 0B (Page 0B-12)”.

ECT Sensor Inspection

B837H11306012

Refer to “DTC “C15” (P0115-H/L): ECT Sensor Circuit

Malfunction in Section 1A (Page 1A-52)”.

Inspect the ECT sensor in the following procedures:

1) Remove the ECT sensor. Refer to “ECT Sensor

Removal and Installation (Page 1C-4)”.

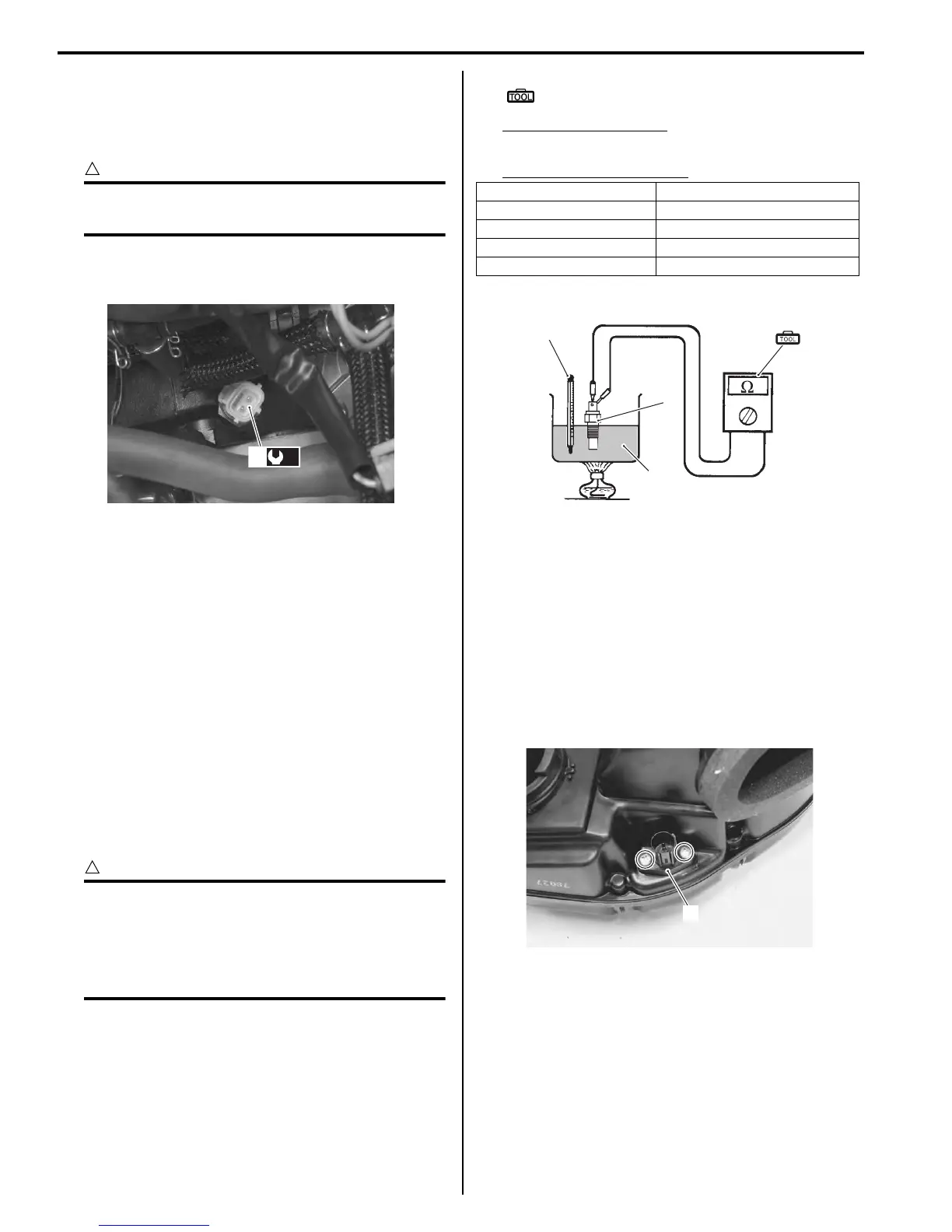

2) Connect the ECT sensor (1) to the circuit tester and

place it in the oil (2) contained in a pan, which is

placed on a stove.

3) Heat the oil to raise its temperature slowly and read

the column thermometer (3) and ohmmeter.

If the ECT sensor ohmic value does not change in

the proportion indicated, replace it with a new one.

CAUTION

!

• Take special care when handling the ECT

sensor. It may cause damage if it gets an

excessive sharp impact.

• Do not contact the ECT sensor and column

thermometer with a pan.

Special tool

(A): 09900–25008 (Multi-circuit tester set)

Tester knob indication

Resistance (Ω)

ECT sensor specification

4) Install the ECT sensor. Refer to “ECT Sensor

Removal and Installation (Page 1C-4)”.

IAT Sensor Removal and Installation

B837H11306013

Removal

1) Remove the air cleaner box. Refer to “Air Cleaner

Box Removal and Installation in Section 1D

(Page 1D-7)”.

2) Remove the IAT sensor (1) from the air cleaner box.

(a)

1

I837H1130029-01

Temperature Standard resistance

20 °C (68 °F) Approx. 2.45 kΩ

50 °C (122 °F) Approx. 0.811 kΩ

80 °C (176 °F) Approx. 0.318 kΩ

110 °C (230 °F) Approx. 0.142 kΩ

(A)

2

1

3

I718H1130014-01

1

I837H1130015-01

Loading...

Loading...