Engine Mechanical: 1D-47

Valve Seat Repair

B837H11406030

The valve seats (1) for both the intake and exhaust

valves are machined to three different angles. The seat

contact surface is cut at 45°.

CAUTION

!

• The valve seat contact area must be

inspected after each cut.

• Do not use lapping compound after the

final cut is made. The finished valve seat

should have a velvety smooth finish but

not a highly polished or shiny finish. This

will provide a soft surface for the final

seating of the valve which will occur

during the first few seconds of engine

operation.

• The titanium valves are coated with an

oxidized membrane treatment to resist

wear but the membrane tend to removed if

lapped after valve seat servicing.

NOTE

After servicing the valve seats, be sure to

check the valve clearance after the cylinder

head has been reinstalled. Refer to “Valve

Clearance Inspection and Adjustment in

Section 0B (Page 0B-4)”.

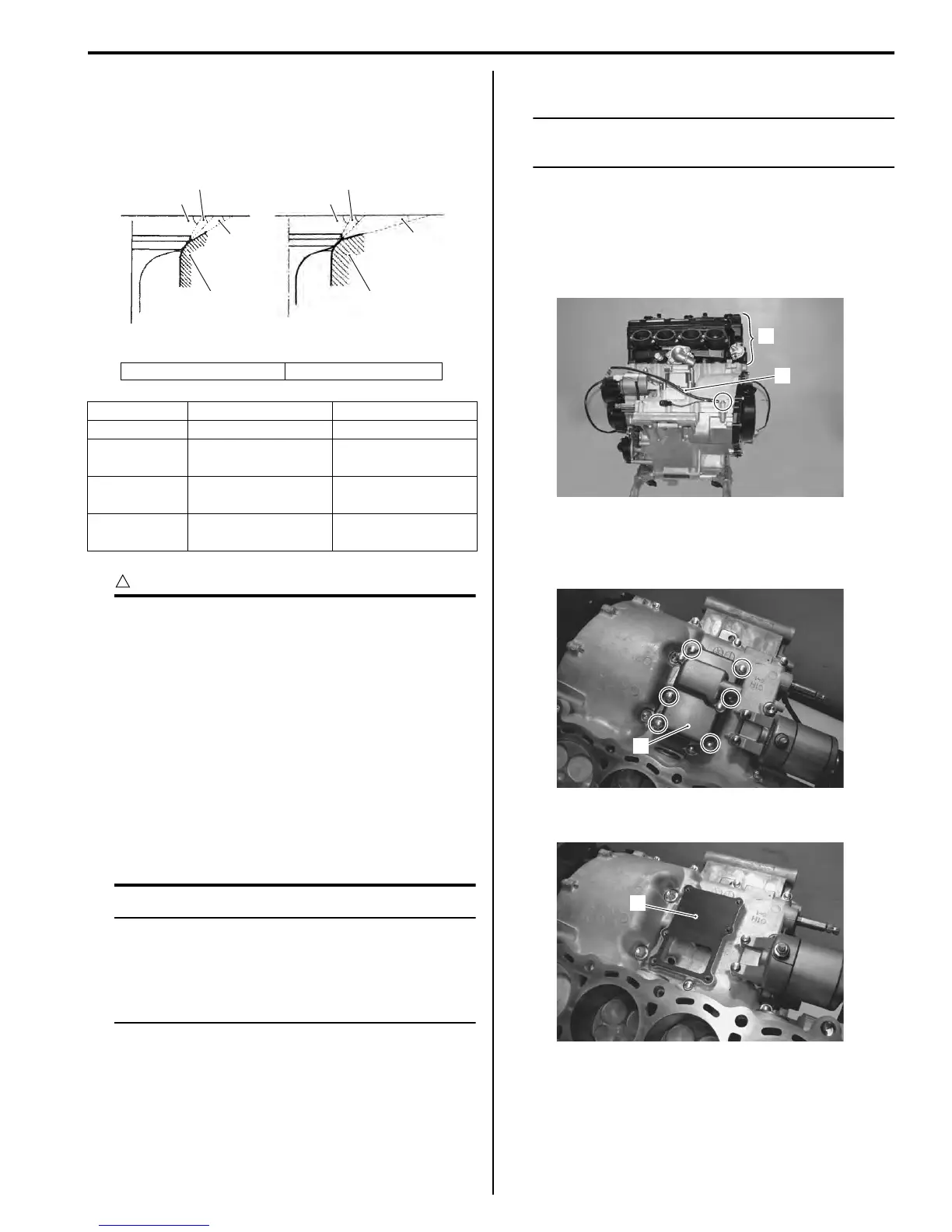

Engine Bottom Side Disassembly

B837H11406035

NOTE

The crankcase must be separated to service

the crankshaft and conrod.

1) Remove the engine assembly from the frame. Refer

to “Engine Assembly Removal (Page 1D-19)”.

2) Remove the engine top side (1). Refer to “Engine

Top Side Disassembly (Page 1D-25)”.

3) Remove the battery (–) lead wire (2).

Crankcase Breather (PCV) Cover

1) Remove the crankcase breather (PCV) cover (1).

2) Remove the gasket (2).

[A]: Intake valve [B]: Exhaust valve

Intake Exhaust

Seat angle 30°/45°/60° 15°/45°/60°

Seat width

0.9 – 1.1 mm

(0.035 – 0.043 in)

←

Valve

diameter

27.2 mm

(1.07 in)

22.0 mm

(0.87 in)

Valve guide

I.D.

4.500 – 4.512 mm

(0.1772 – 0.1776 in)

←

60q

1

45q

15q

60q

45q

30q

1

[A] [B]

I837H1140069-01

1

2

I837H1140303-01

1

I837H1140070-01

2

I837H1140071-01