Engine Mechanical: 1D-73

Conrod Crank Pin Bearing Removal and

Installation

B837H11406044

Refer to “Engine Bottom Side Disassembly (Page 1D-

47)”.

Refer to “Engine Bottom Side Assembly (Page 1D-54)”.

Removal

Remove the conrod crank pin bearings (1).

NOTE

• Do not remove the bearings (1) unless

absolutely necessary.

• Make a note of where the bearings are

removed from so that they can be

reinstalled in their original positions.

CAUTION

!

When removing the bearings, be careful not

to scratch the conrods and the bearings.

Installation

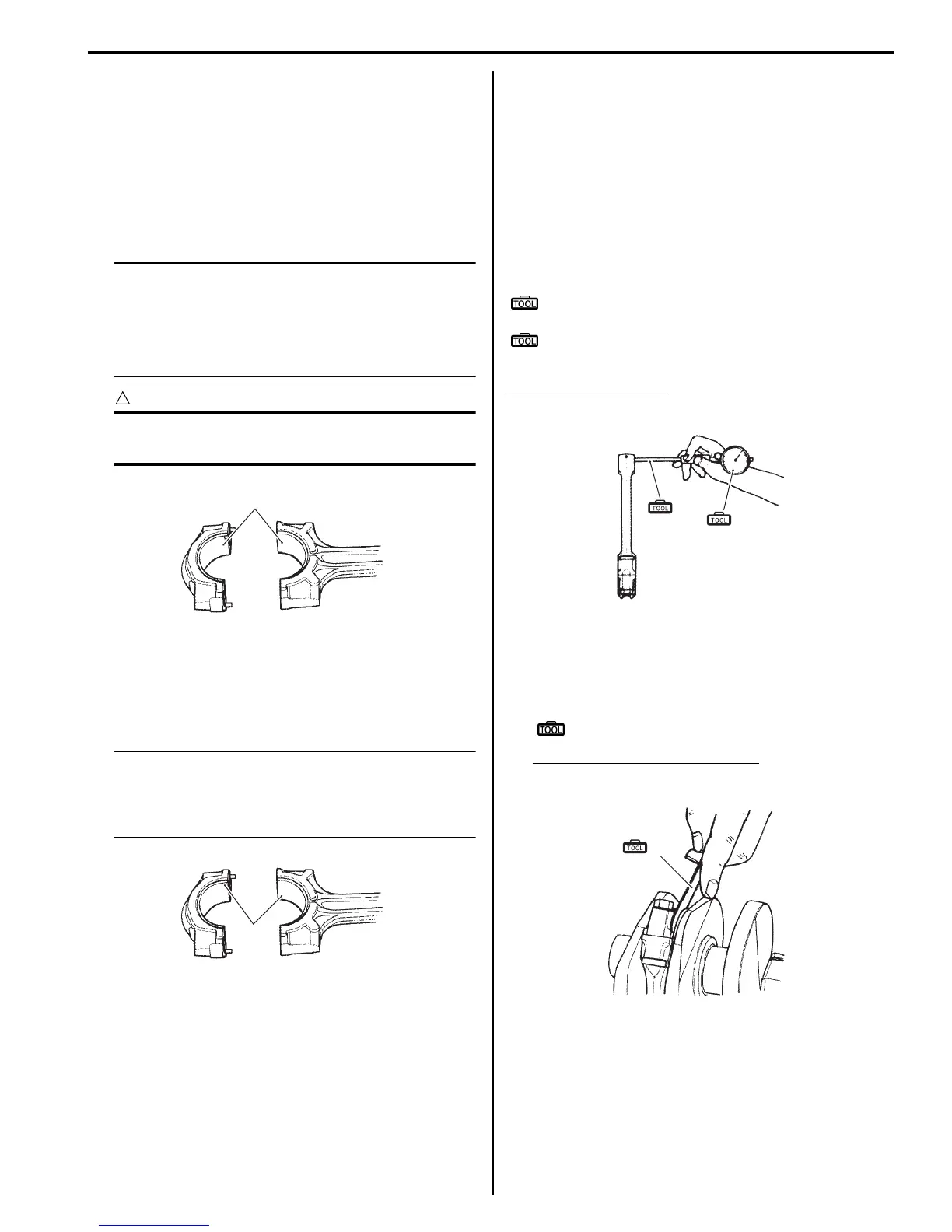

When installing the bearings into the conrod cap and

conrod, be sure to install the tab “A” first, and then press

in the other opposite side of the bearing.

NOTE

Inspect and select the conrod crank pin

bearing if necessary. Refer to “Conrod Crank

Pin Bearing Inspection and Selection

(Page 1D-74)”.

Conrod and Crankshaft Inspection

B837H11406040

Refer to “Engine Bottom Side Disassembly (Page 1D-

47)”.

Refer to “Engine Bottom Side Assembly (Page 1D-54)”.

Conrod Small End I.D.

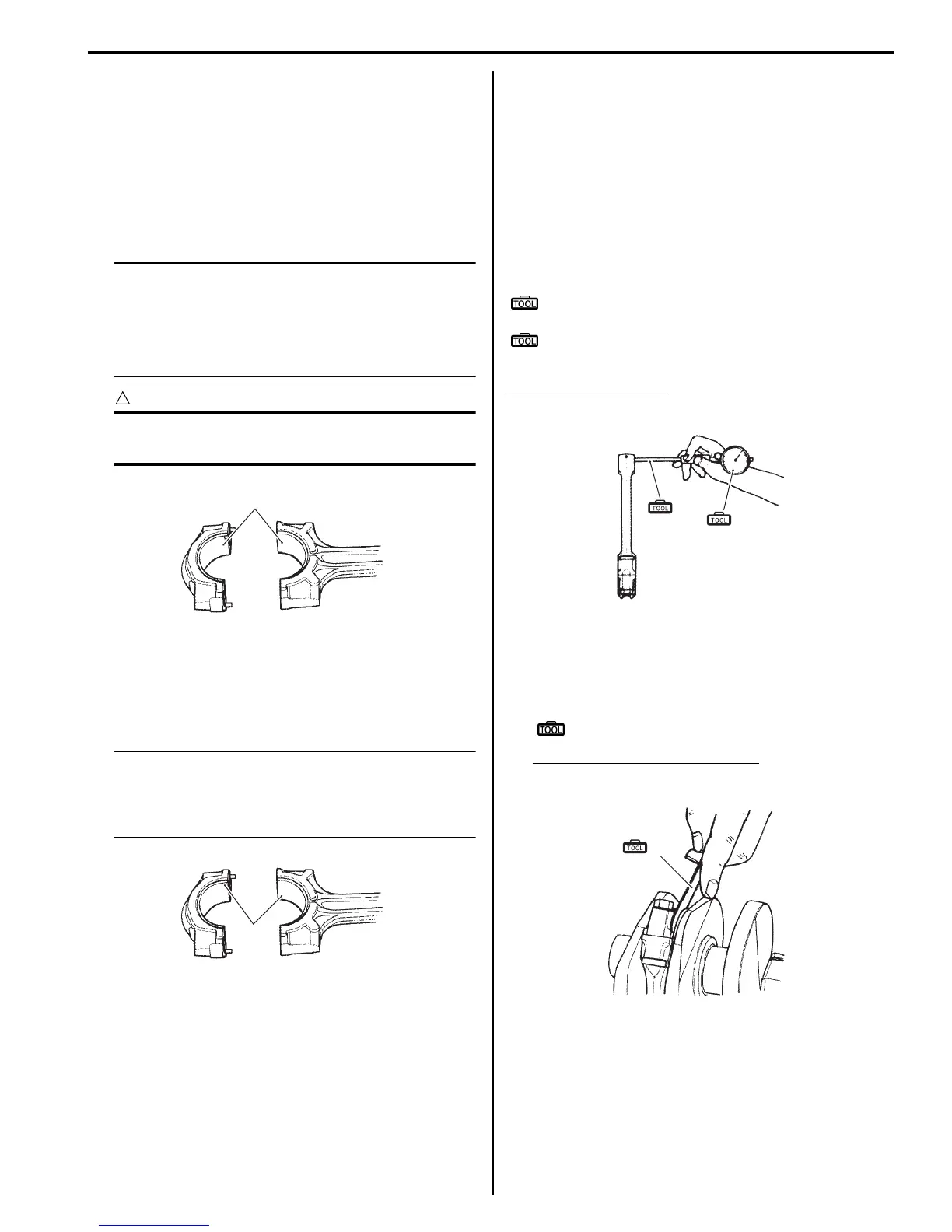

Measure the conrod small end inside diameter using the

small bore gauge.

If the conrod small end inside diameter exceeds the

service limit, replace the conrod.

Special tool

(A): 09900–20602 (Dial gauge (1/1000 mm, 1

mm))

(B): 09900–22401 (Small bore gauge (10 – 18

mm))

Conrod small end I.D.

Service limit: 14.040 mm (0.5528 in)

Conrod Big End Side Clearance

1) Check the conrod big end side clearance using the

thickness gauge.

Special tool

(A): 09900–20803 (Thickness gauge)

Conrod big end side clearance

Service limit: 0.3 mm (0.012 in)

1

I718H1140269-01

“A”

I823H1140578-01

(B)

(A)

I823H1140280-01

(A)

I823H1140281-01

Loading...

Loading...