1D-47 Engine Mechanical:

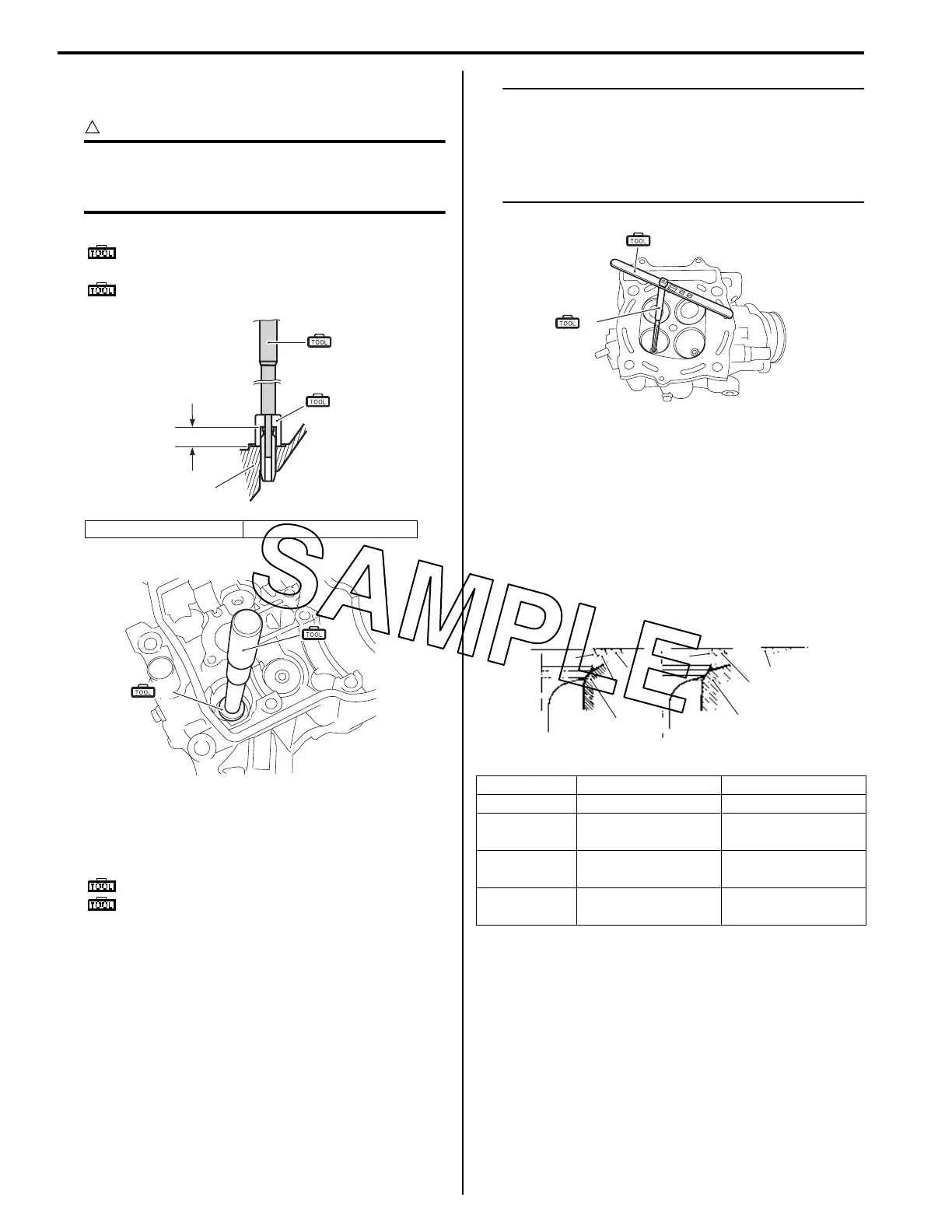

7) Drive the guide into the guide hole using the valve

guide installer.

CAUTION

!

Failure to oil the valve guide hole before

driving the new guide into place may result in

a damaged guide or head.

Special tool

(A): 09916–44310 (Valve guide remover/

installer)

(D): 09916–53360 (Attachment)

8) After installing the valve guides, refinish their guiding

bores using the reamer. Be sure to clean and oil the

guides after reaming.

Special tool

(C): 09916–34542 (Reamer handle)

(E): 09916–34550 (Valve guide reamer (5.5

mm))

NOTE

• Be sure to cool down the cylinder head to

ambient air temperature.

• Insert the reamer from the combustion

chamber and always turn the reamer

handle clockwise.

9) Reassemble the cylinder head. Refer to “Cylinder

Head Disassembly and Assembly” (Page 1D-39).

10) Install the cylinder head assembly. Refer to “Engine

Top Side Assembly” (Page 1D-30).

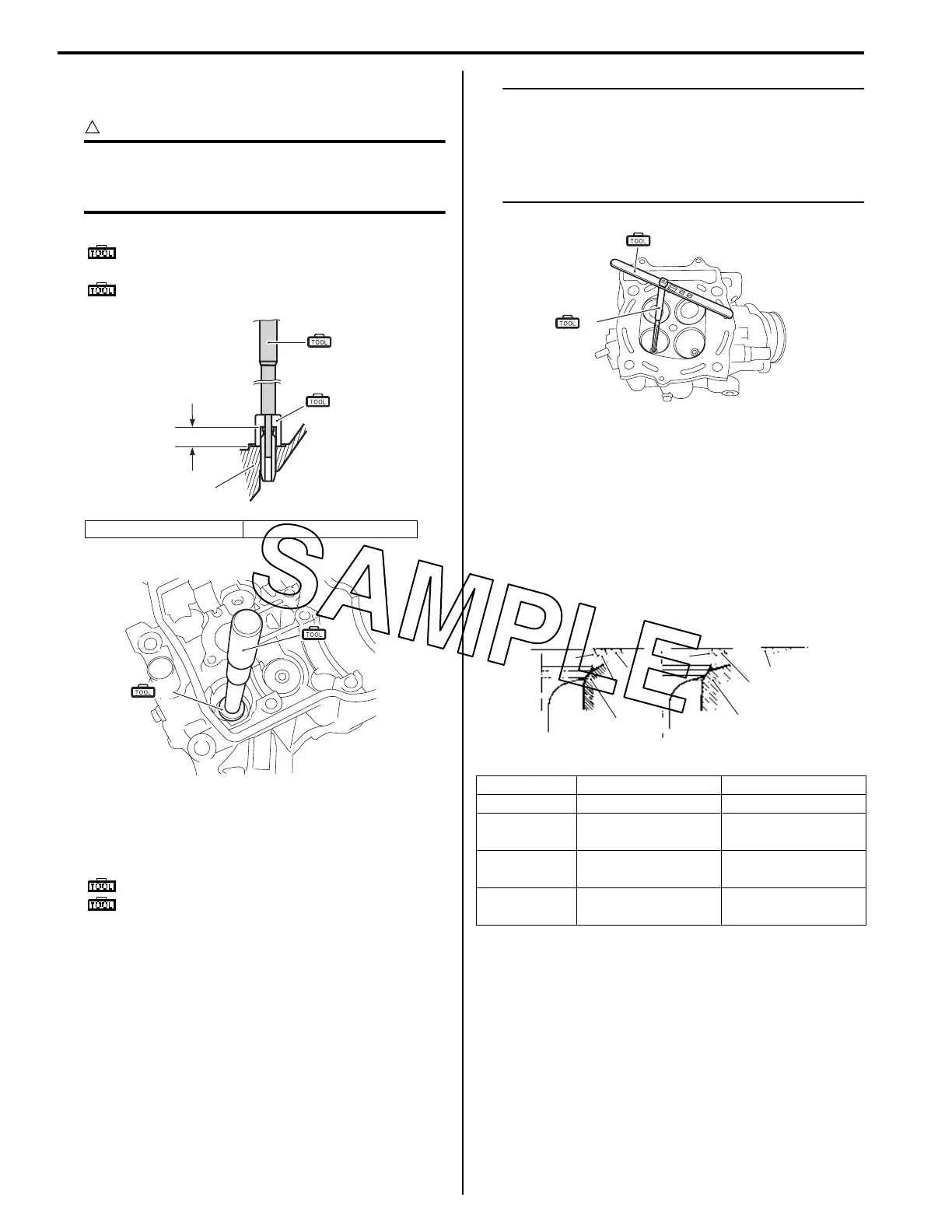

Valve Seat Repair

BA02J21406028

The valve seats (1) for both the intake and exhaust

valves are machined to three different angles. The seat

contact surface is cut at 45°.

1. Cylinder head “a”: 12.2 mm (0.48 in)

“a”

(A)

(D)

1

I718H1140127-01

(D)

(A)

IA02J1140037-01

Intake Exhaust

Seat angle 30°/45°/60° 15°/45°/60°

Seat width

0.9 – 1.1 mm

(0.035 – 0.043 in)

←

Valve

diameter

36 mm

(1.42 in)

31 mm

(1.22 in)

Valve guide

I.D.

5.500 – 5.512 mm

(0.2165 – 0.2170 in)

←

(C)

(E)

IA02J1140038-02

1

1

60°

30°

45°

15°

45°

60°

IN EX

I831G1140170-02

Loading...

Loading...