Maintenance and Lubrication: 0B-20

Drive Chain Inspection and Adjustment

BA02J20206018

Inspect drive chain

Clean lubricate and inspect each time the

motorcycle is ridden

Drive Chain Visual Check

1) With the transmission in neutral, support the

motorcycle using a jack.

2) Visually check the drive chain for the possible

defects listed as follows. If any defects are found, the

drive chain must be replaced. Refer to “Drive Chain

Replacement” in Section 3A (Page 3A-6).

• Loose pins

• Damaged rollers

• Dry or rusted links

• Kinked or binding links

• Excessive wear

• Missing O-ring seals

NOTE

When replacing the drive chain, replace the

drive chain and sprockets as a set.

Drive Chain Plate Wear Inspection

Measure the height of the inner “A” and outer “B” plates

using the vernier calipers. If any of the measurements

exceeds the service limit, replace the drive chain with a

new one.

Chain plate height

Service limit: (Inner “A”): 12.75 mm (0.502 in)

Service limit: (Inner “B”): 11.20 mm (0.441 in)

Special tool

: 09900–20101 (Vernier calipers (150 mm))

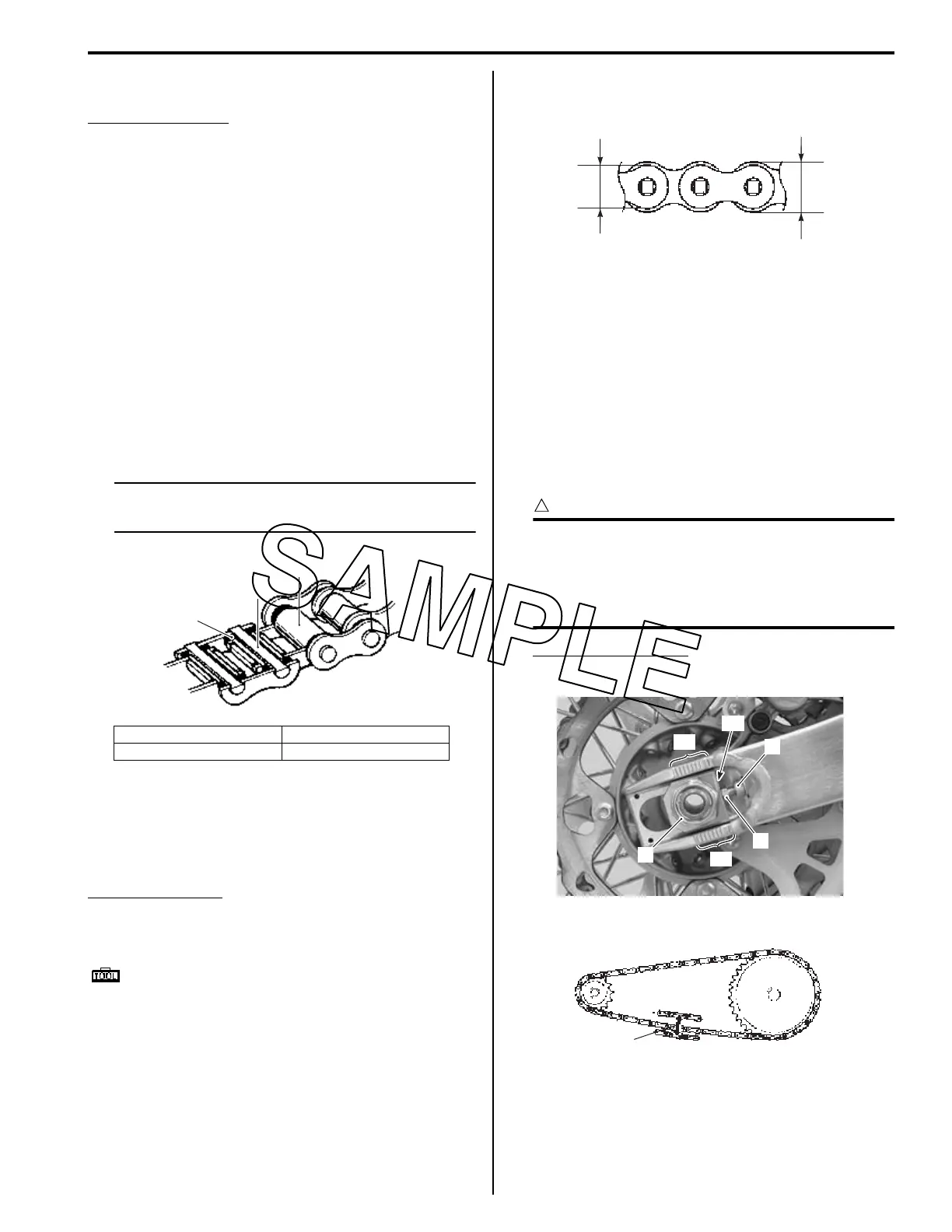

Drive Chain Slack Adjustment

1) Place the motorcycle on the side-stand.

2) Loosen the axle nut (1).

3) Loosen the left and right chain adjuster lock-nuts (2).

4) Loosen or tighten both chain adjuster bolts (3) until

there is 40 – 50 mm (1.6 – 2.0 in) of slack “a” at the

middle of the chain between the engine and rear

sprockets as shown in the figure.

CAUTION

!

The reference marks “A” on both sides of the

swingarm and the grooved line “B” of each

chain adjuster must be aligned to ensure that

the front and wear wheels are correctly

aligned.

Drive chain slack “a”

Standard 40 – 50 mm (1.6 – 2.0 in)

1. O-ring seal 3. Roller

2. Grease

1

2

3

IA02J1020046-01

“A”“B”

IA02J1020047-01

“A”

“A”

1

2

3

“B”

IA02J1020048-01

“a”

I649G1020036-02