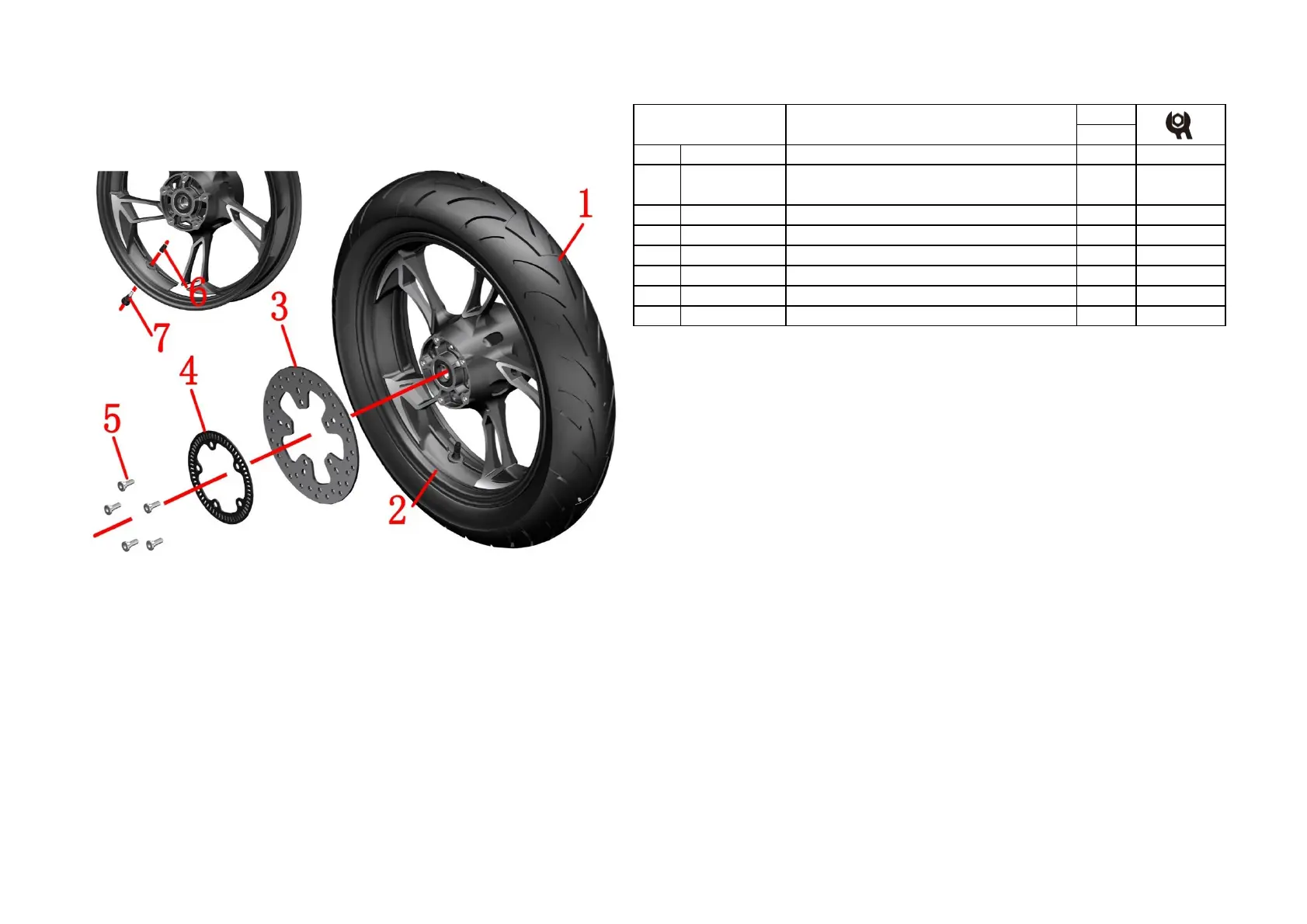

4-REAR WHELL COMPONENT 21

CHK

ADJ

N

O. PART NO.

2 1091200-023000

KD150-U bright black rear rim (3.5×17)

1

3

1100100-600000

KD150-U rear brake disc (230 × 4.5 / KD)

1

4

1274200-058000

ABS induction ring (60 teeth)

1

5 1251100-117093

Non-standard inner hex bolt M8×25(color zinc)

5

22

~

6 1230200-006000

7 1230100-047000

Environmental vacuum tyre valve spile(TR

-

PROCEDURE:

●Disc brake plate, ABS gear ring

Using 6# inner hexagon socket remove bolts⑸,remove ABS gear ring⑷ and disc brake plate⑶。

●Tire and rim assembly

Disassemble tire valve cap⑹. Deflate the tire with tools. Then disassemble the rear tire⑴ with professional tire

changing machine. Disassemble the tire valve⑺ with suitable tool.

●Maintenance

Tire: Check regularly the tire on cracks and air pressure.If the tire is ware to the marker, change the tire with

same specification. See details in user manual. Ingradiant of tire include semi hot melt rubber. Area with too high

temperature is not suitable. If temparature of outdoor is too low, storing the motorcycle in warm place or indoor

is suggested in order to avoid frost crack. Normal temperaturestandard 250kPa.

Rim: Check if the rim has deformation or crack. Support the rim horizontally and check if it can rotate

smoothly. Specification of oil seal on rear rim is φ47×φ28×7. Bearing type: 6204-2RS.

Disc brake plate: Thickness can not be less than 4mm. If not, change it.

CAUTION:

●Be careful while disassembling the tire and rim in case of damages on the components.

●After changing the tire, check air proof performace and dynamic balance.

●Disqualified tire repair liquid might corrode the rim and cause safety risk.

●Not enough tire pressure can cause abnormal wear and tare. Too high pressure in summer might have

possibility of tire bursting.

●It needs running-in for about 300km after changing new rear disc brake plate. During this period, leave

enough braking distance while riging.

1 1230100-446000

130/70-17 (CMNK01) environmental protection

vacuum tire

1

Fig.4 REAR WHELL

COMPONENT

Rear wheel component 2

Loading...

Loading...