ESP program features 59

Pump impeller cleaning

The Pump impeller cleaning procedure consists of a programmable sequence of

motor running forward and reverse for the defined number of cycles. The cleaning

function removes the solids stuck to impeller blades and thus reduces the friction and

inertial losses during normal operation.

The function can be triggered using:

1. Explicit command trigger - provided by the user through Fieldbus or digital input.

2. On schedule - repeated regularly based on user timer setting.

The ongoing cleaning operation can be interrupted either manually or automatically

based on actual load supervision.

• Supervision high function can be used to abort currently running cleaning cycle to

avoid motor overheating in case of abnormal load peaks.

• Supervision low function can be used to abort the whole cleaning sequence if load

detected in course of cleaning step is below a reasonable limit. The reduced load

can be interpreted as green light to switch to production state.

Settings

Parameter group 81 Pump cleaning (page 440).

Warnings D200 Cleaning max warning (page 586).

Faults D100 Cleaning max fault (page 605).

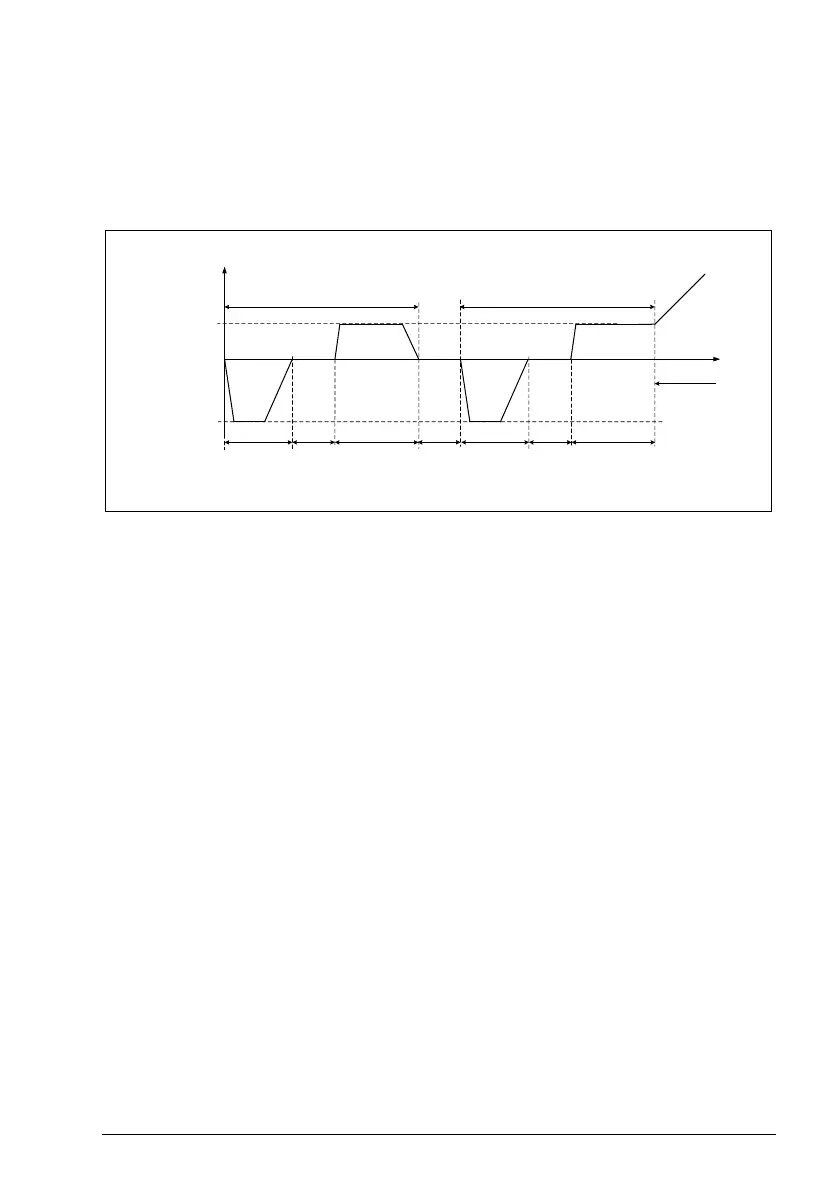

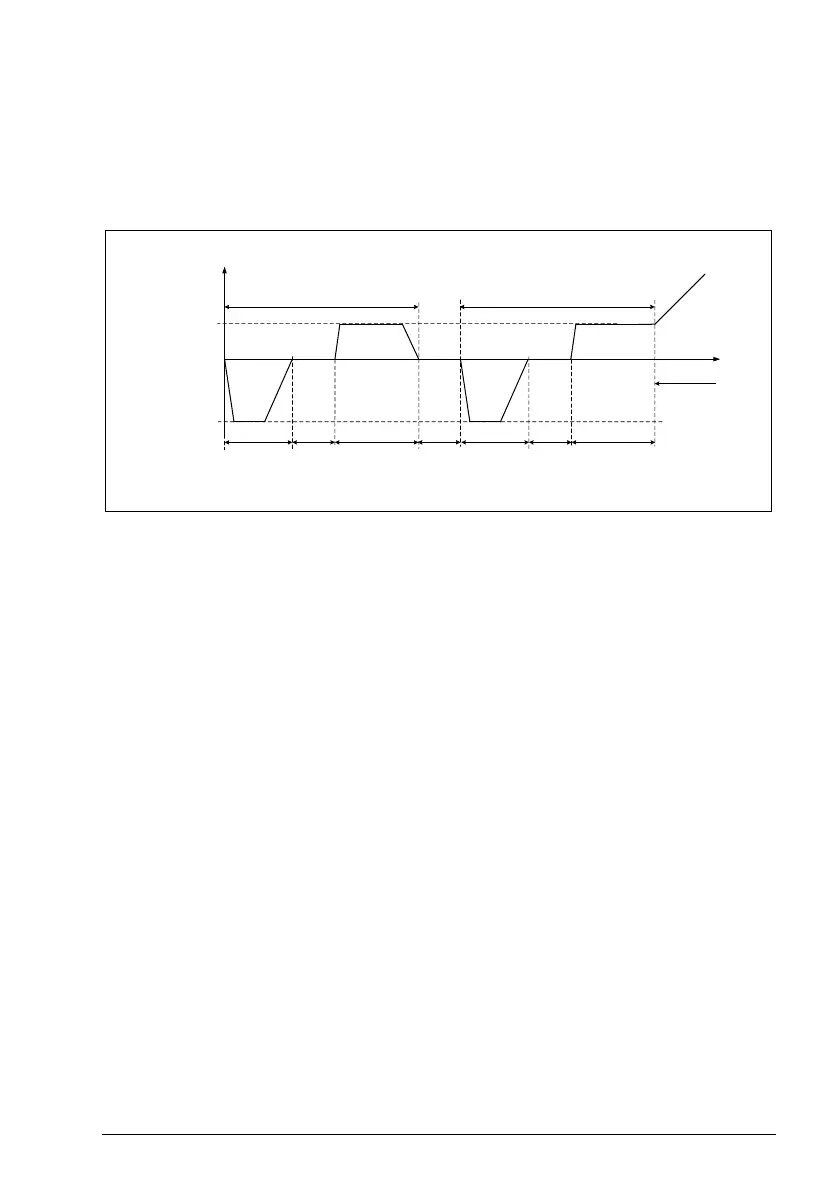

Speed reference

Time

81.24 Second

step reference

81.21 First

step reference

81.22

First step

time

81.23

Off

time

81.25

Second

step time

81.23

Off

time

0

Production

state

Cleaning cycle 1

Cleaning cycle 2

81.22

First step

time

81.23

Off

time

81.25

Second

step time

Loading...

Loading...