1MAC309294-MB F Section 9

Other functions

RER620 431

Technical Manual

9.1.5 Signals

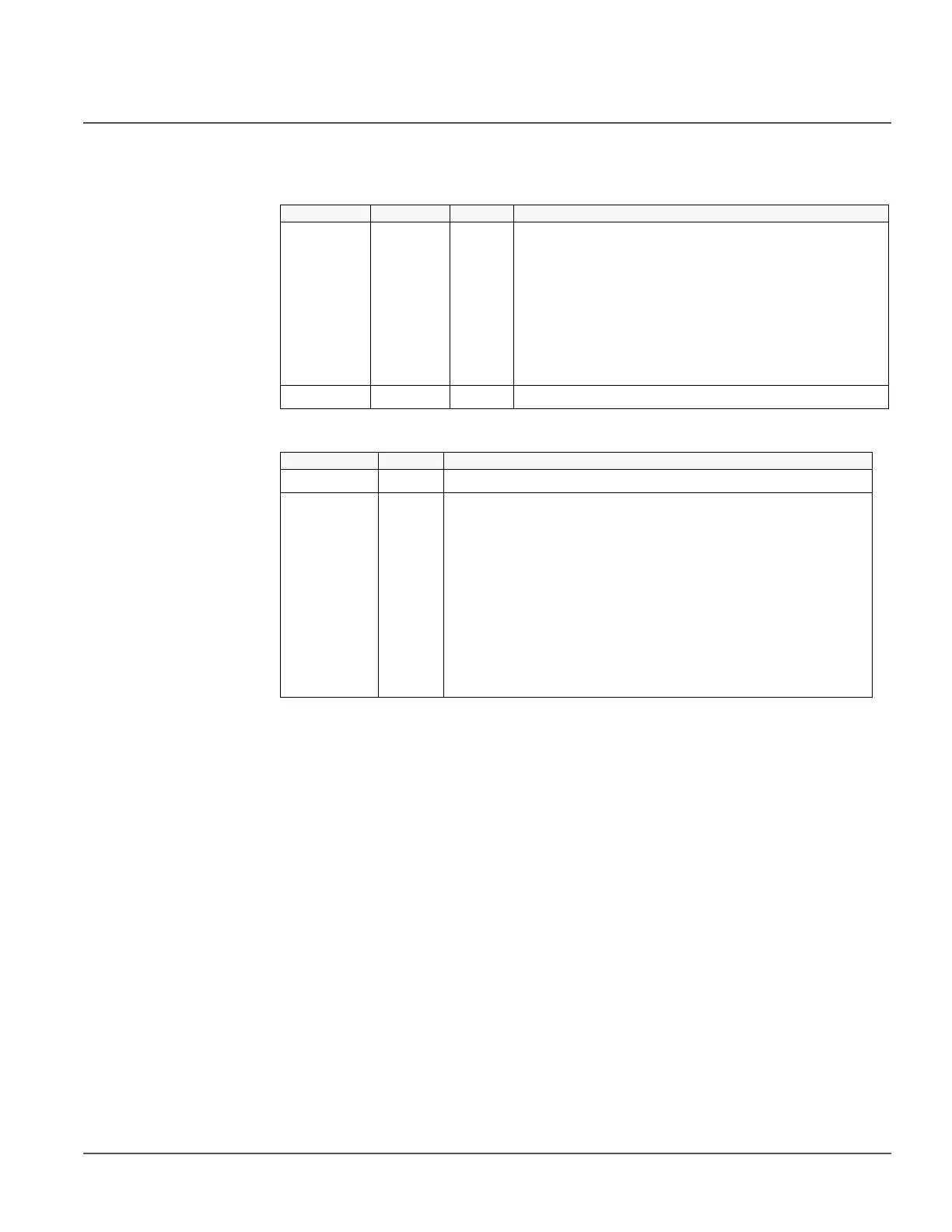

Table 385: UPS input signals

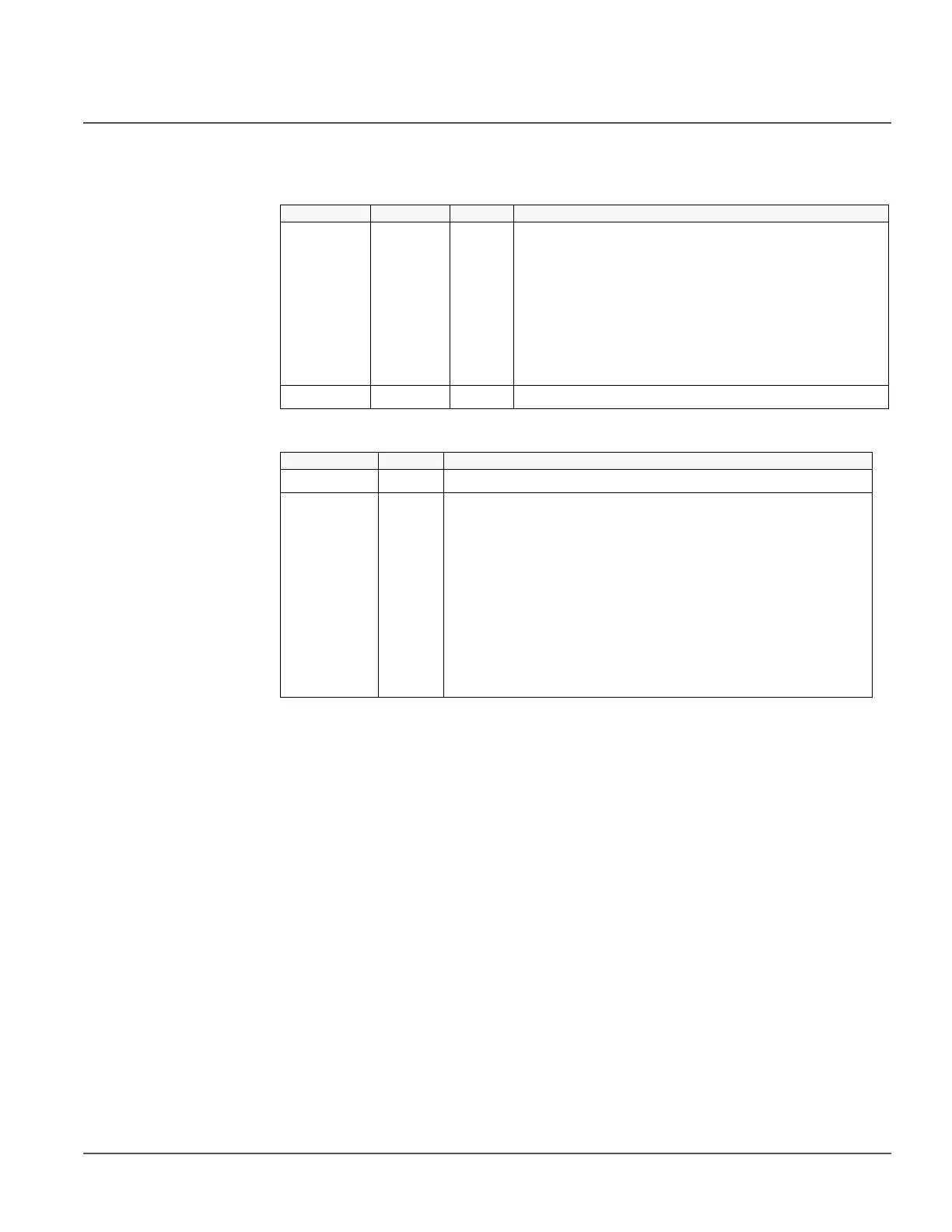

Table 386: UPS output signals

9.1.6 CVD Voltage Clamping

It is possible for some embedded Capacitor Voltage Divider (CVD) sensors to measure, a

voltage in excess of +/-4% tolerance, under conditions of extreme humidity or wetting of

pole surfaces. The 'CVD clamping' function clamps the measured voltage from the CVD

sensors, to within +/- 4% of a reference voltage. The Clamping function is intended to be

used with certain types of reclosers, please contact ABB for further clarification.

The necessary reference voltage can be obtained by connecting three external potential

transformers (PTs) to the V1abc or V2abc analog inputs of the relay [Refer to Figure 186].

Alternately, in the absence of the three external PTs, the PT used to power up the recloser

control cabinet may be used as the reference when connected to the V1abc or V2abc inputs

of the relay [Refer to Figure 187]. All applicable limitations are listed at the end of the

section.

Name Type Default Description

START_TST BOOLEAN 0=False This tests the battery’s charge and overall health by briefly

connecting a low resistance load parallel to the battery and then

measuring the battery voltage. The battery voltage before the

load was applied and the voltage during the time the load is

applied are compared to determine battery health. The load is

about 1.5 ohms, and the connection time for the load is 0.1

seconds. Ten measurements are taken and averaged together in

the last 25 milliseconds of the test period resulting in the battery

voltage test measurement. After the battery is tested, a cool

down period for the UPS’s battery load resistors is required.

During the cool down period, the battery test function is blocked.

Reset UPS BOOLEAN 0=False Resets the microprocessor of the UPS

Name Type Description

TST_VOLT SIGNAL Battery voltage after test in Vdc

TST_RESULT ENUM Indicates the battery test result:

0 = Ready for battery test

1 = Battery test is registered

2 = Battery interrupt for PWM3 is now enabled and is used as a timer

3 = Battery test in process (lasts about 0.075 second during which Boost

and Battery Charge functions are disabled

4 = Battery test in process, and measurements are being taking (lasts

about 0.025 second

5 = Battery test has been completed for 25 milliseconds, now take non-test

battery voltage

6 = In cool-down period

7 = 60VDC rail voltage too low to test

8 = Within ten seconds of reset (must be at least 10 seconds out of reset to

start battery test)

Loading...

Loading...