130 Rockwell Automation Publication 2097-UM002D-EN-P - April 2017

Appendix A Interconnect Diagrams

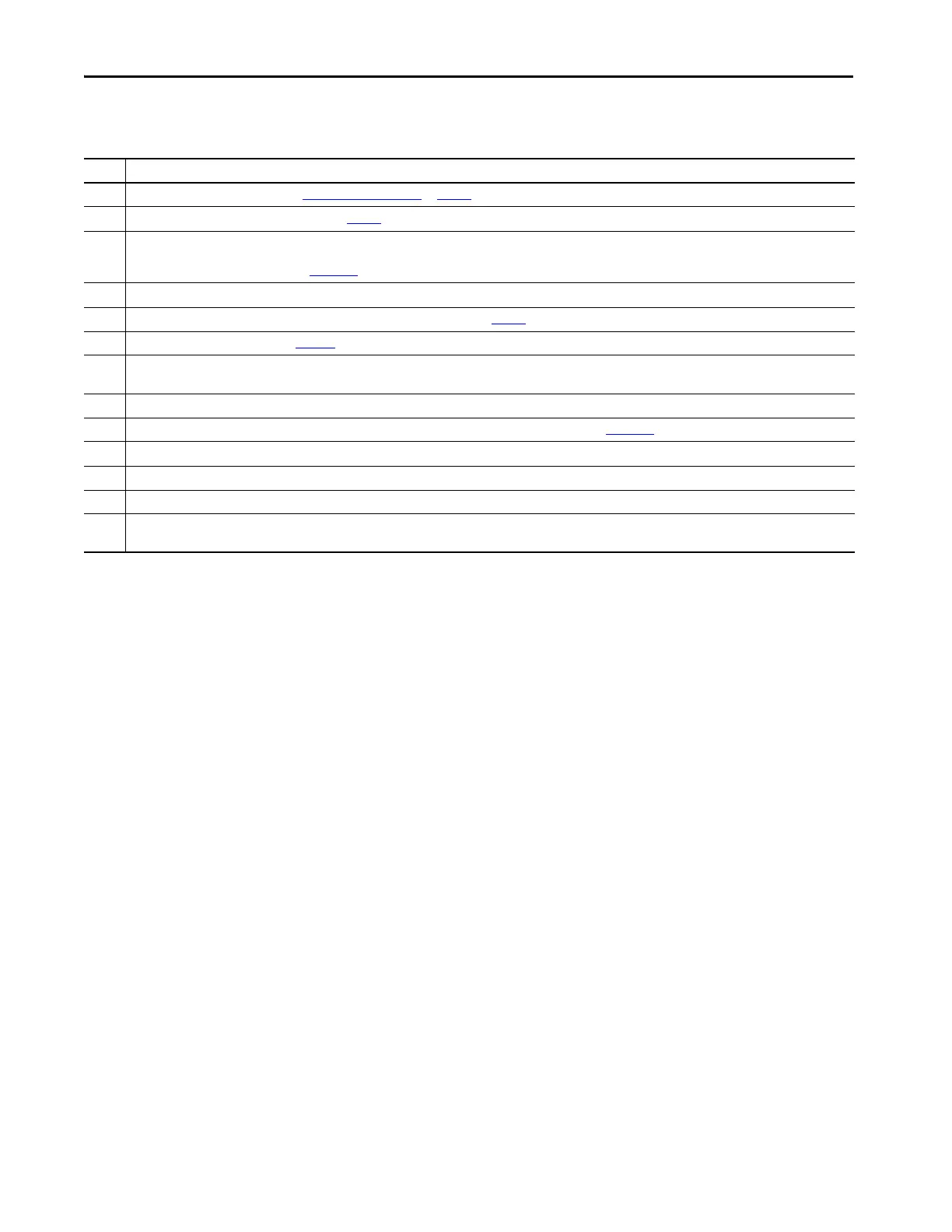

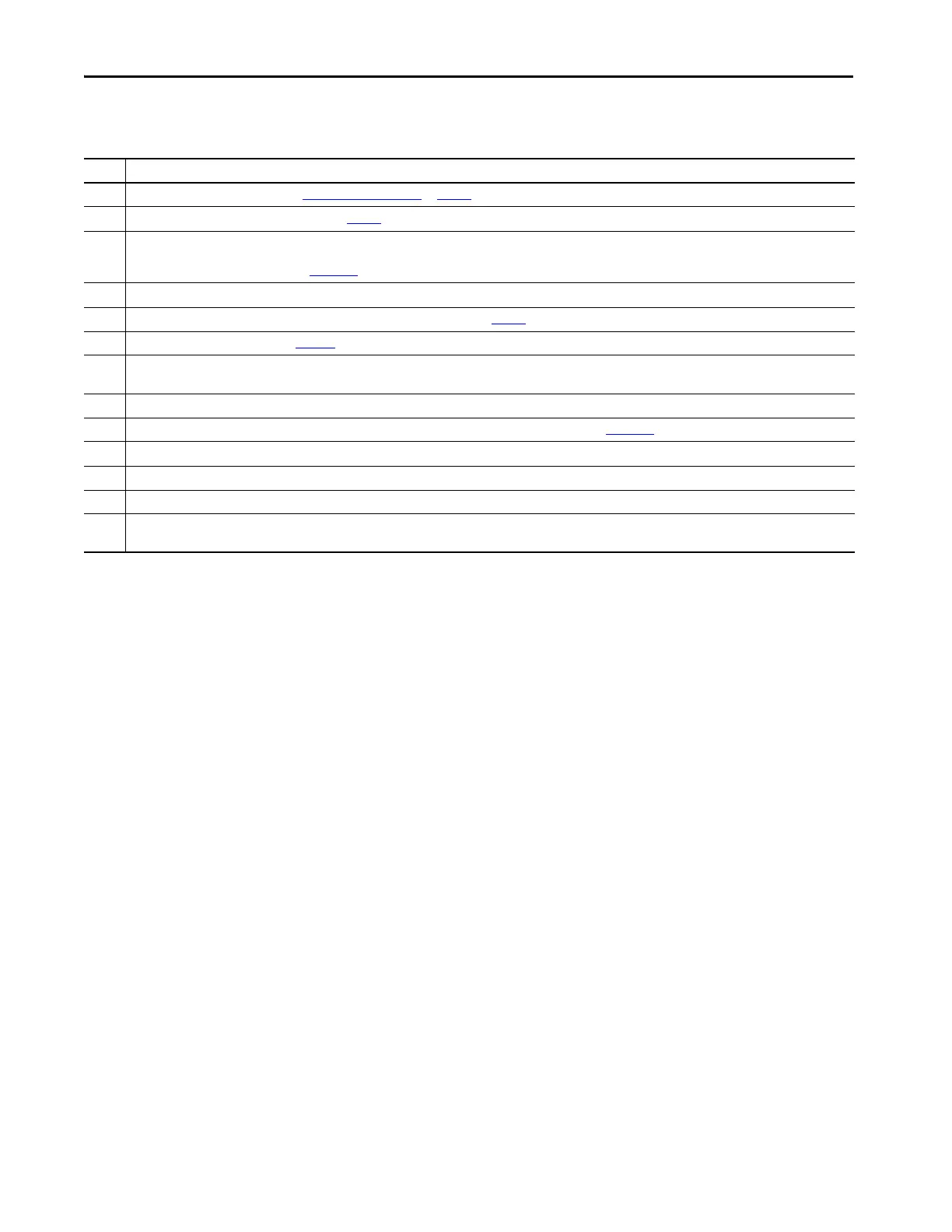

Interconnect Diagram Notes

This appendix provides wiring examples to assist you in wiring the Kinetix® 350

system. These notes apply to the wiring examples on the pages that follow.

Note Information

1 For power wiring specifications, refer to Power Wiring Requirements

on page 60.

2 For input fuse and circuit breaker sizes, refer to on page 18.

3 Place the AC (EMC) line filters as close to the drive as possible and do not route very dirty wires in the wireway. If routing in wireway is unavoidable, use shielded cable

with shields that are grounded to the drive chassis and filter case. For AC line filter specifications, refer to Kinetix 350 Drive Power Specifications in Kinetix Servo Drives

Specifications Technical Data, publication KNX-TD003

.This filter does not apply to 2097-V32PRx-LM drives because they have integrated AC line filters.

4 Terminal block is required to make connections.

5 Contactor coil (M1) needs integrated surge suppressors for AC coil operation. See on page 18

6 See the Motor Brake Currents table on page 140 to size the interposing relay for your application and for a detailed schematic of brake implementation.

7 Drive Enable input must be opened when main power is removed, or a drive fault occurs. A delay of at least 1.0 second must be observed before attempting to enable the

drive after main power is restored.

8 Cable shield clamp must be used to meet CE requirements. No external connection to ground is required.

9 For motor cable specifications, refer to the Kinetix Motion Accessories Specifications Technical Data, publication KNX-TD004

.

10 Motor power cables (catalog numbers 2090-XXNPMF-xxSxx and 2090-CPBM6DF-16AAxx) have a drain wire that must be folded back under the cable shield clamp.

11 MPL-Axxx and MPL-B15xxx-H...MPL-B45xxx-H, MPM-Axxx, MPF-Axxx, MPS-Axxx, MPAR-Axxx, MPAI-Axxx, and MPAS-Axxx, encoders use the +5V DC supply.

12 MPL-B15xxx-S/M...MPL-B45xxx-S/M, MPM-Bxxx, MPF-Bxxx, MPS-Bxxx, MPAR-Bxxx, MPAI-Bxxx, and MPAS-Bxxx, encoders use +9V DC.

13 Brake connector pins are labeled plus (+) and minus (-) or F and G respectively. Power connector pins are labeled U, V, W, and GND or

A, B, C, and D respectively.

Loading...

Loading...