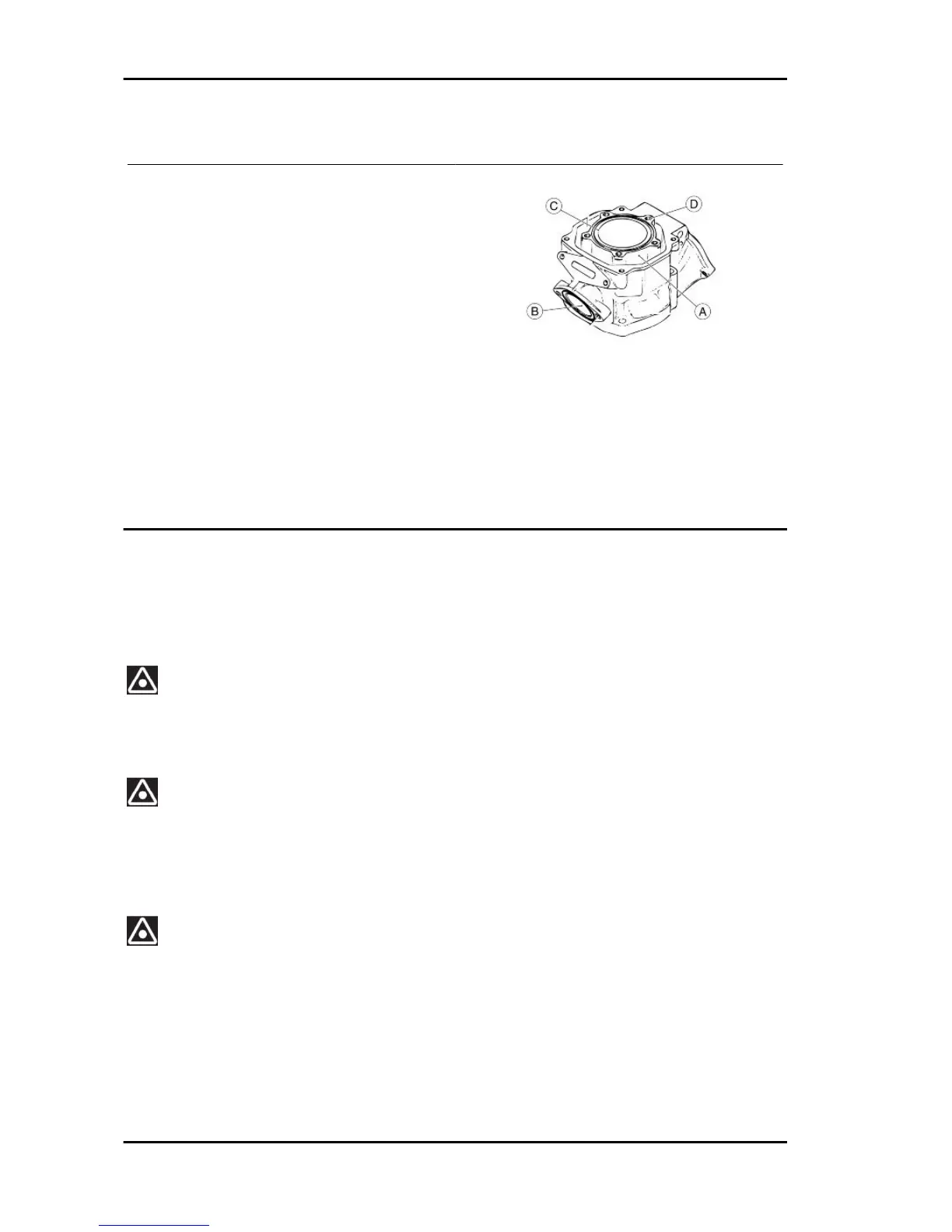

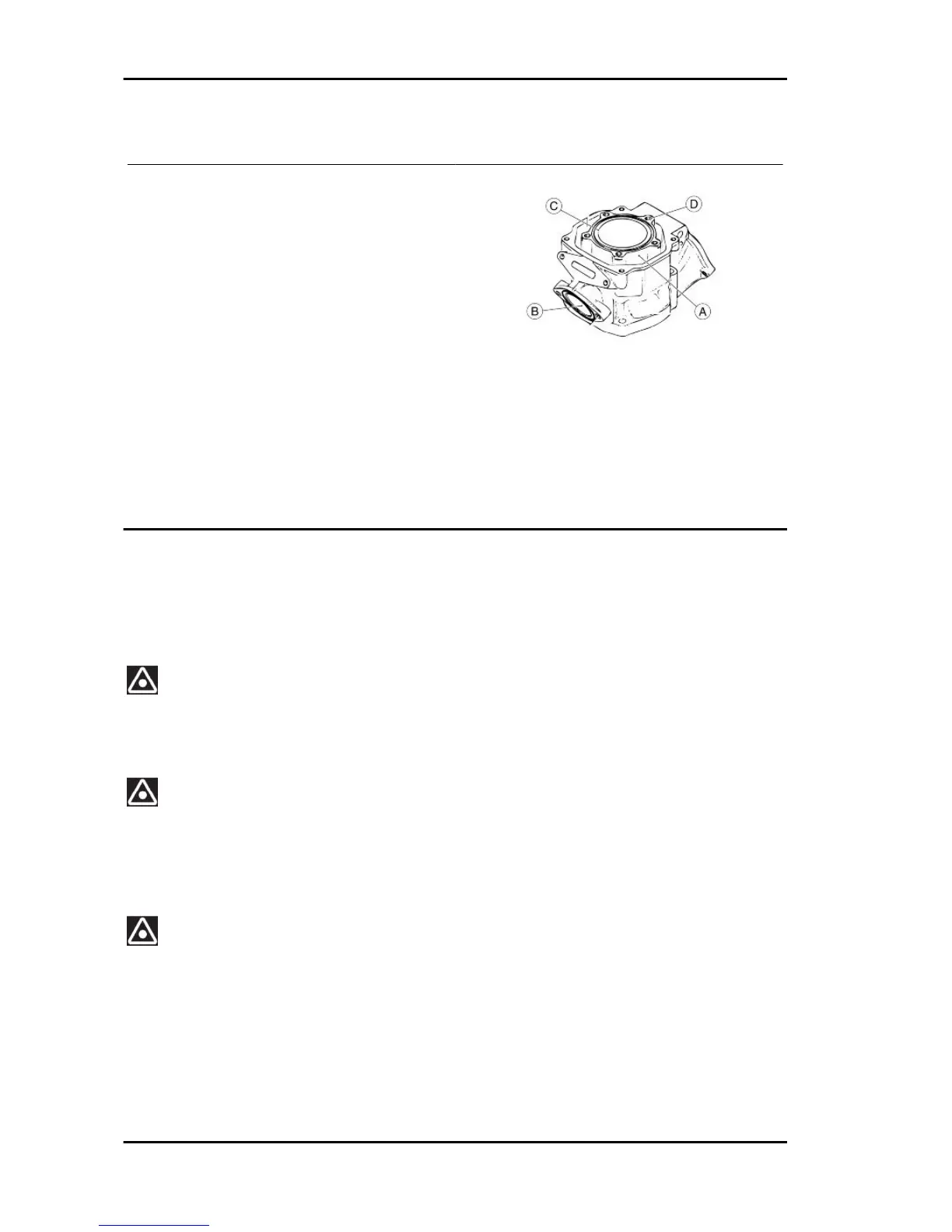

Checking the cylinder

•

Remove any scales formed by water in

the cooling interspace on the cylinder

(A).

•

Clean off any combustion deposits

from the outlet port (B).

•

Clean and check the groove of the O-

ring (C).

•

Make sure all threads (D) are in proper

conditions.

•

Make sure all the seal surfaces are

smooth and not damaged.

•

Check the cylinder wall for wear.

Ovality: max. wear limit 0.02 mm (0.0008 in).

Checking the piston

•

Check if there are marks of pinging/head knocking on the "squish" area and the piston cen-

tre.

•

Make sure the piston is not damaged or shows signs of pressure or galling.

SLIGHT SCORINGS CAN BE ELIMINATED BY RUBBING THEM WITH EMERY CLOTH (GRAIN 600

- 800).

•

Clean the piston crown and the bottom side as well as the piston ring grooves.

CLEAN THE RING GROOVES THOROUGHLY WITH A SCRAPER OR PREFERABLY WITH A

PIECE OF AN OLD PISTON RING.

•

Clearance between piston and wall = Cylinder diam. - Piston diam.; Nominal clearance 0.020

- 0.035 mm (0.00079 - 0.00138 in); Max. wear limit 0.080 mm (0.00315 in).

IF THIS WEAR LIMIT IS EXCEEDED, USE AN OVERSIZED PISTON OR REPLACE BOTH THE

CYLINDER AND THE PISTON.

WHEN THE PISTON IS REPLACED, ALSO REPLACE THE TWO SEEGER RINGS (1), THE PIN (2)

AND THE BALL RETAINER (3).

Engine RX SX 125

ENG - 108

Loading...

Loading...