Checking the counter shaft

•

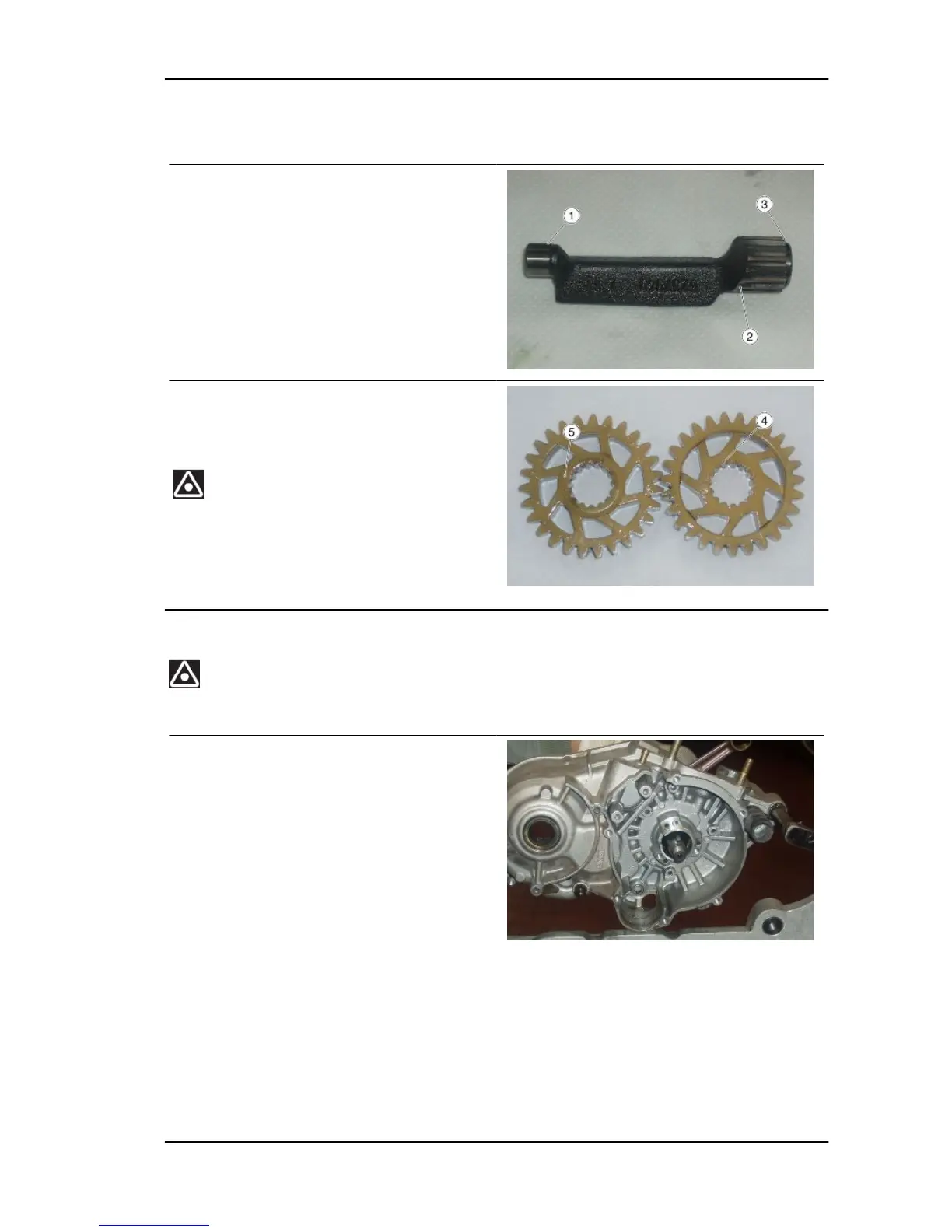

Check countershaft for wear: (1) Fly-

wheel side bearing seat, Minimum

wear limit diameter: 14.94 mm (0.5882

in) ; (2) Clutch side bearing seat, Mini-

mum wear limit diameter: 24.94 mm

(0.9819 in) ;

•

Make sure the groove of the snap ring

(3) is not worn or damaged.

•

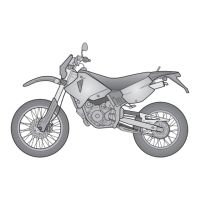

Check the internal (4) and external

toothing (5) of the gears controlling the

countershaft for wear.

THE GEARS AND THE O-RINGS ON THE REAR SIDE OF

THE COUNTERSHAFT GEAR ON THE CRANKSHAFT

MUST BE REPLACED AFTER 15,000 KM.

Installing the crankshaft

UPON REFITTING, ALWAYS REPLACE THE GASKETS, THE SAFETY CIRCLIPS, THE O-RINGS

AND THE OIL SEALS REMOVED.

•

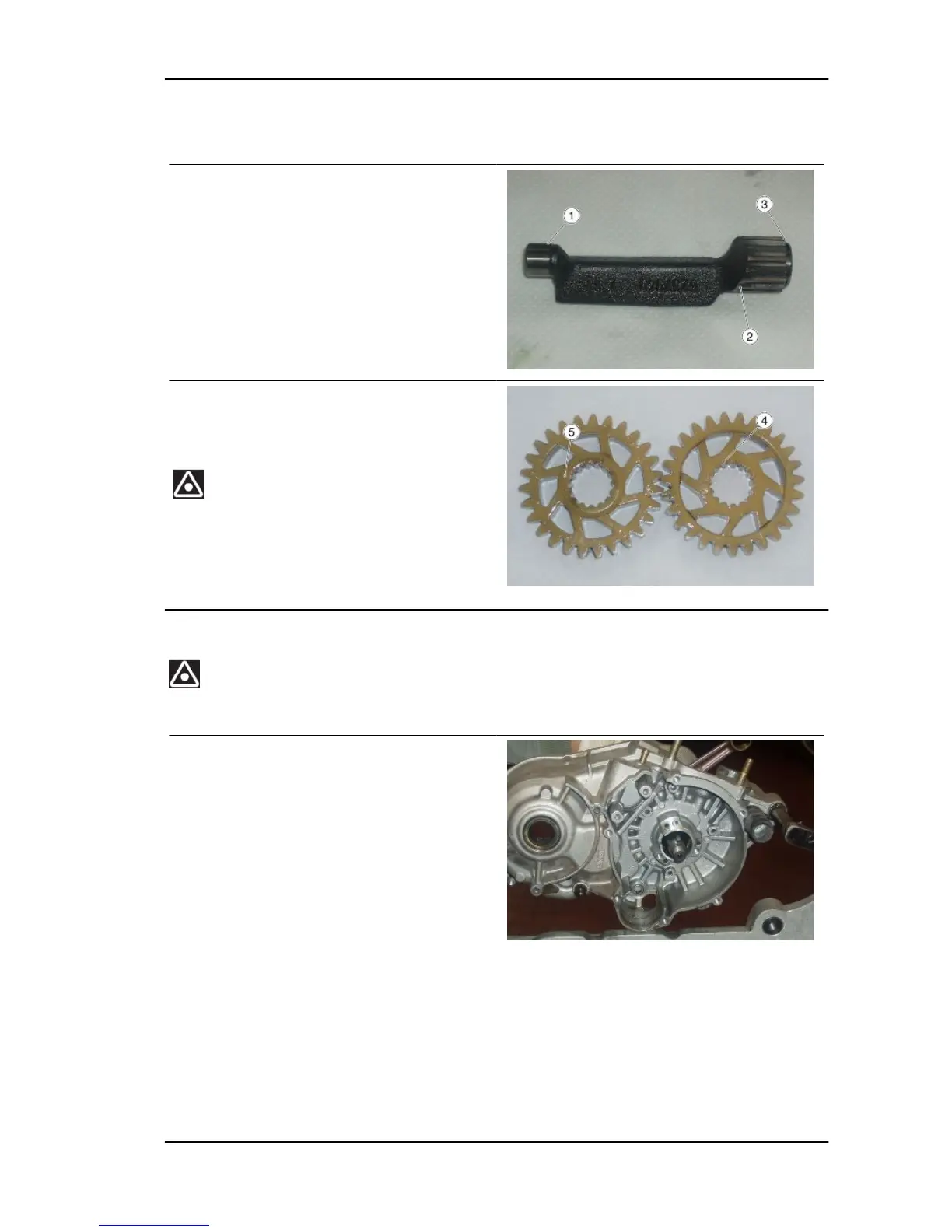

Pre-warm the crankcase at 90 - 100 °

C (194 - 212 °F)

•

Fix the flywheel side crankcase half to

the support and tighten the screw and

the spacer.

•

If necessary, fit the shim washers nee-

ded to the flywheel side crankcase half.

•

Apply LOCTITE Anti-Seize on the

bearing seats on the crankshaft.

•

Heat up the engine crankcase.

•

Fit the bearings in their seats in the

crankcase.

•

Assemble the crankshaft in the warm

crankcase.

RX SX 125 Engine

ENG - 121

Loading...

Loading...