•

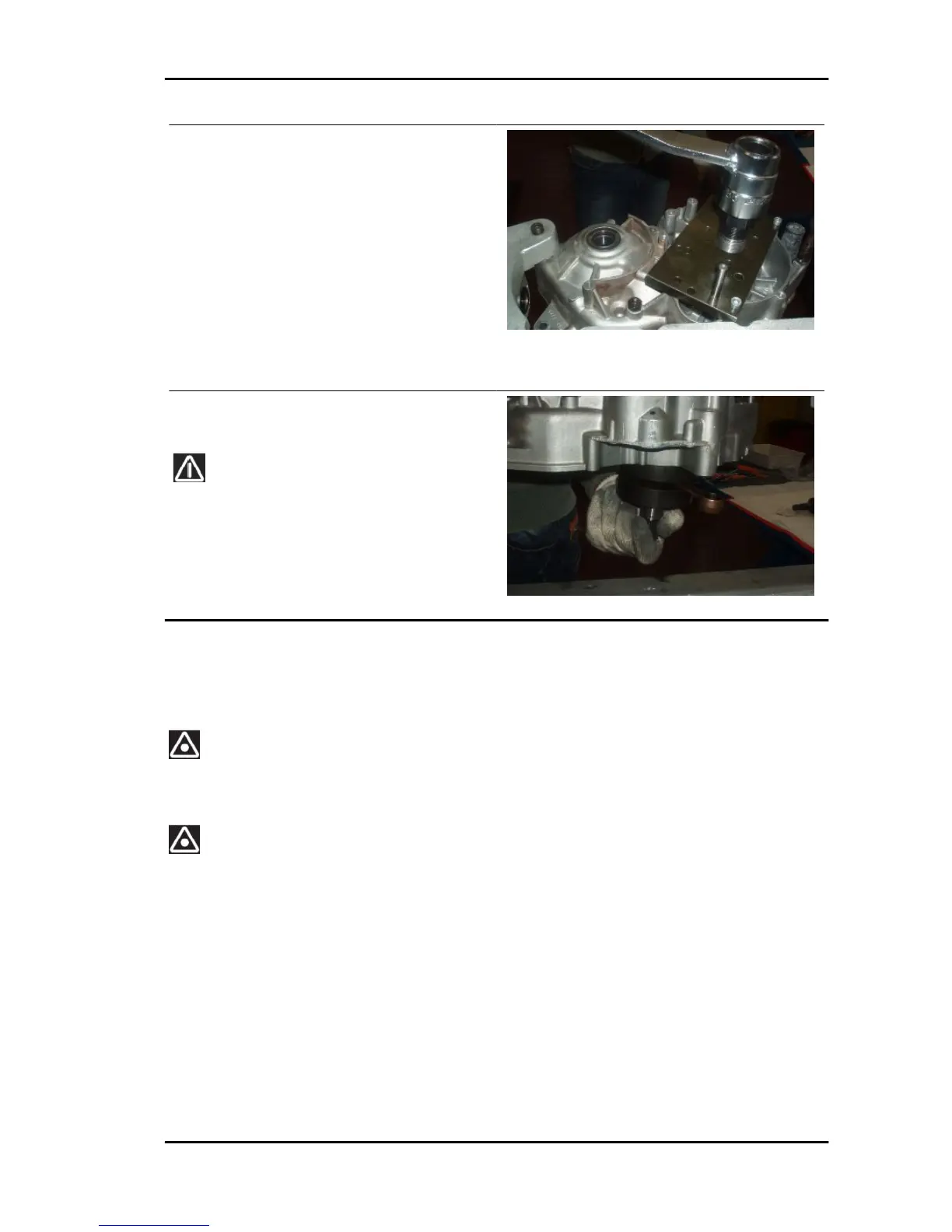

Place the extractor plate and fix it with

four M6 fixing screws, but do not fully

tighten them.

•

Adequately centre the tool.

•

Tighten the four M6 fixing screws.

•

Insert the extractor screw with the long

threaded end in the extractor plate.

Specific tooling

AP0277455 Extractor plate to separate the

crankcase halves

•

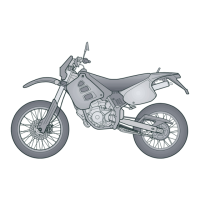

Thrust out the crankshaft operating on

the extractor plate screw.

ACT WITH CAUTION WHEN EXTRACTING THE CRANK-

SHAFT AS IT IS HEAVY.

SUPPORT IT ADEQUATELY SO AS TO AVOID DAMAGES.

Inspecting the crankcase halves

•

Clean the crankcase halves, the ball bearings and all the bearing gaskets with a non-ag-

gressive detergent.

DO NOT USE DEGREASERS OR SOLVENTS.

•

Clean all the seal surfaces.

BE CAREFUL NOT TO DAMAGE THE SEAL SURFACES WHEN CLEANING THEM.

•

Check that the crankcase halves show no signs of cracks or any kind of damage.

•

Check that the oil flow in the main bearings is not obstructed; clear the passage with com-

pressed air if required.

•

Check that the pin of the contact screw moves smoothly and that the spring is pre-loaded.

The round end of the pin should not be worn. Fix the contact screw with SILASTIC 732 RTV.

•

When the water delivery intake is replaced, fix it with LOCTITE 648.

•

Make sure that the oil seals are not worn or damaged.

RX SX 125 Engine

ENG - 117

Loading...

Loading...