•

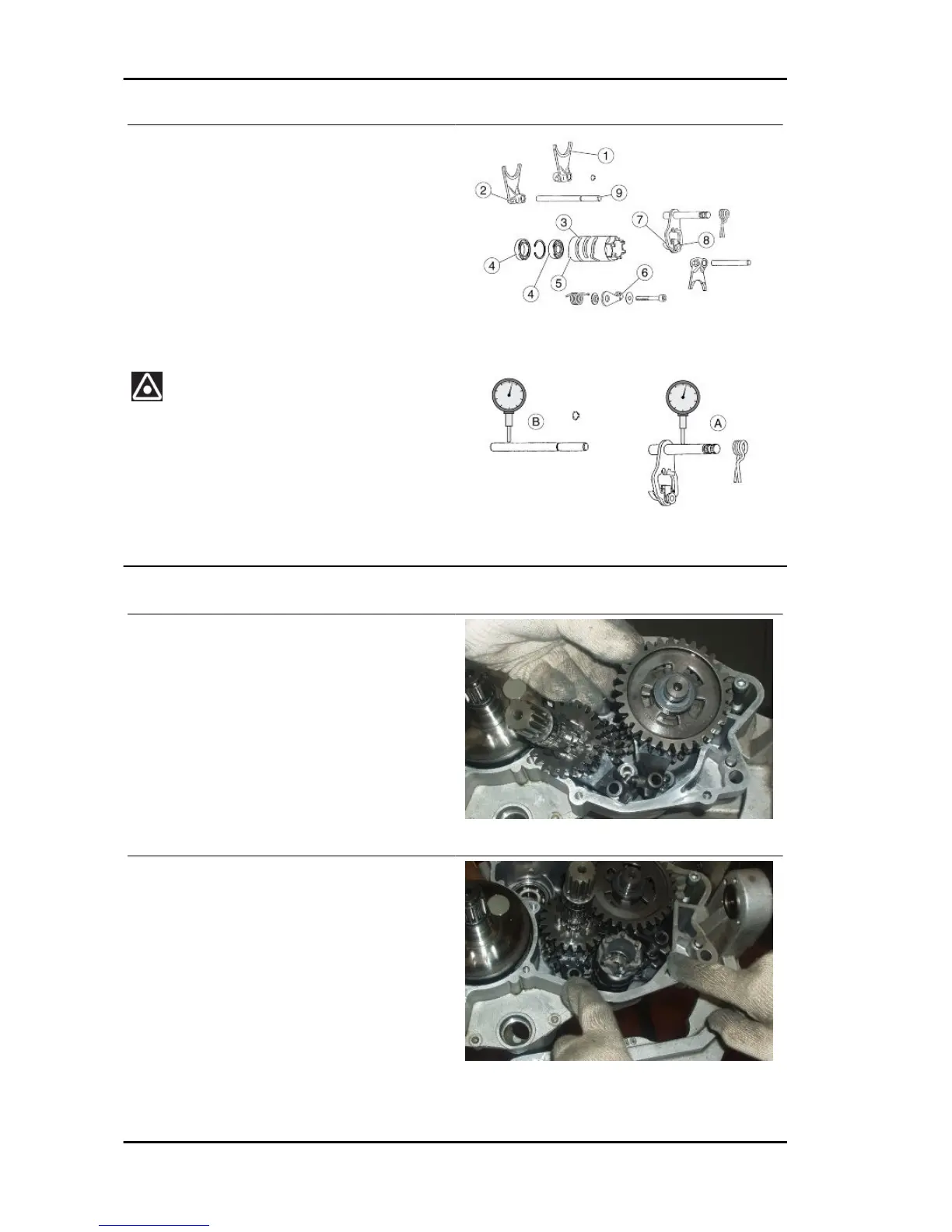

The lever roller (6) must rotate freely.

•

Check that the stop tab (7) and the rel-

evant spring (8) work properly.

•

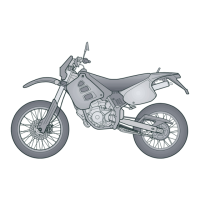

Check that the gear shaft is not de-

formed. (A) Max. admissible deviation

= 0.15 mm (0.0059 in);

•

Check that both fork shafts are not de-

formed. (B) Max. admissible deviation

= 0.05 mm (0.0020 in);

THE END OF THE FORK LONG SHAFT (9) THAT PRO-

TRUDES FROM THE CRANKCASE IS USED AS A TRANS-

MISSION STOP AND CAN BE BENT IN CASE OF EXCES-

SIVE LOAD (BUMPING).

THE DEVIATION CAN BE CHECKED BY REMOVING THE

CLUTCH COVER AND ROTATING THE LONG SHAFT.

Assembling the gearbox

•

Place the guiding sleeve on the pri-

mary shaft to avoid damaging the oil

seal.

•

Heat up the engine crankcase.

•

Apply LOCTITE Anti-Seize on the

bearing seats present on the crank-

case.

•

Fit the bearings in their seats.

•

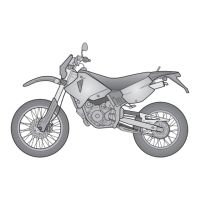

Fit the gear unit.

•

Fit the 5th - 6th gear fork on the gear

pinion of the secondary shaft.

•

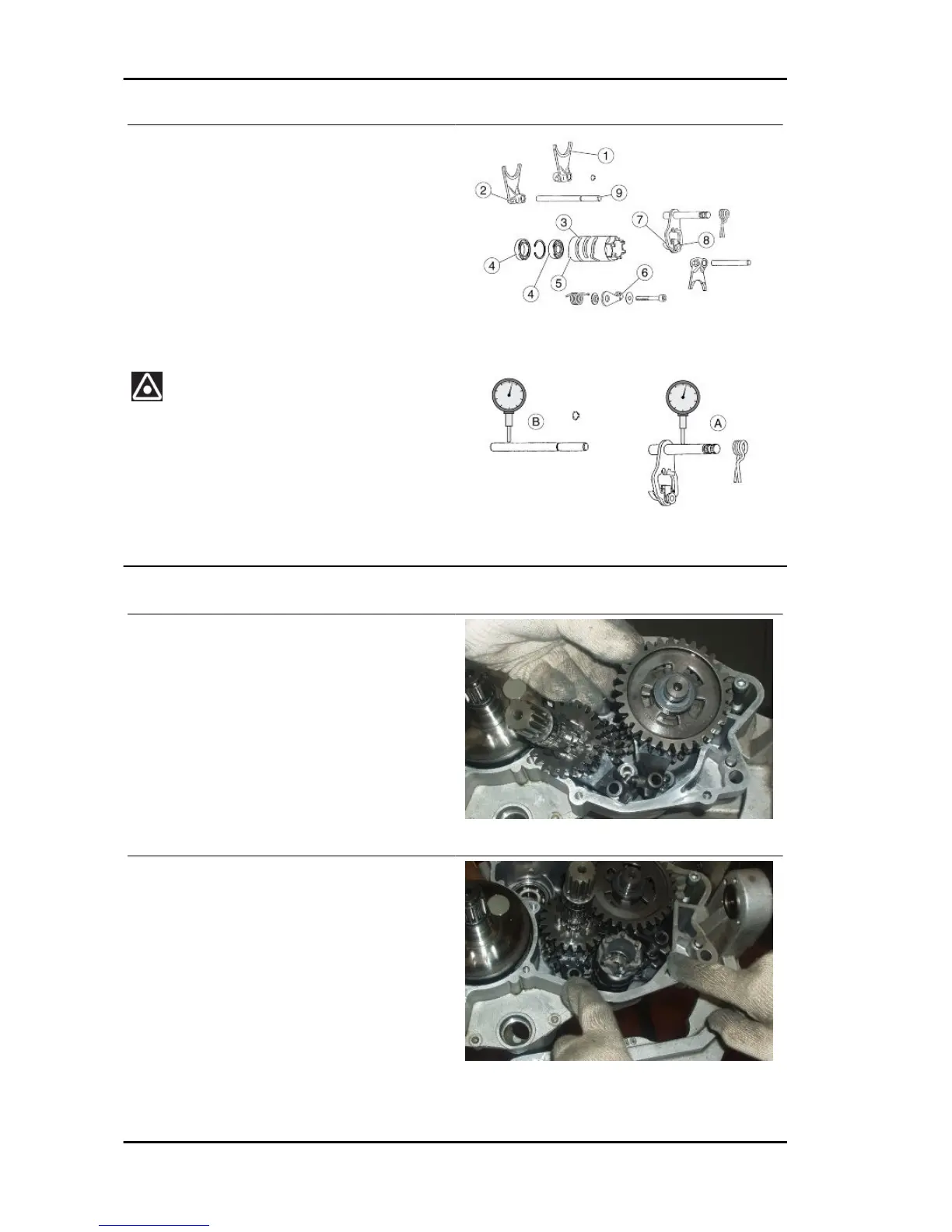

Place the 2nd - 3rd gear fork and the

1st - 4th gear fork on the gear pinion of

the primary shaft. The 2nd - 3rd gear

fork must be installed with the printed

number 123 facing upwards. The 1st -

4th gear fork must be installed with the

printed number 113 facing upwards.

Engine RX SX 125

ENG - 92

Loading...

Loading...