SECTION : 4B

MASTER CYLINDER

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS 4B–1. . . . . . . . . . . . . . . . . . . . . . . . . .

FASTENER TIGHTENING SPECIFICATIONS 4B–1.

DIAGNOSIS 4B–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHECKING BRAKE PROPORTIONING VALVE 4B–1

MAINTENANCE AND REPAIR 4B–3. . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 4B–3. . . . . . . . . . . . . . . . . . . . .

MASTER CYLINDER ASSEMBLY 4B–3. . . . . . . . . . .

BRAKE FLUID RESERVOIR 4B–5. . . . . . . . . . . . . . . .

PROPORTIONING VALVE 4B–7. . . . . . . . . . . . . . . . . .

UNIT REPAIR 4B–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MASTER CYLINDER OVERHAUL 4B–8. . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION 4B–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MASTER CYLINDER 4B–11. . . . . . . . . . . . . . . . . . . . .

PROPORTIONING VALVE 4B–11. . . . . . . . . . . . . . . . .

FLUID LEVEL SENSOR 4B–11. . . . . . . . . . . . . . . . . . .

SPECIFICATIONS

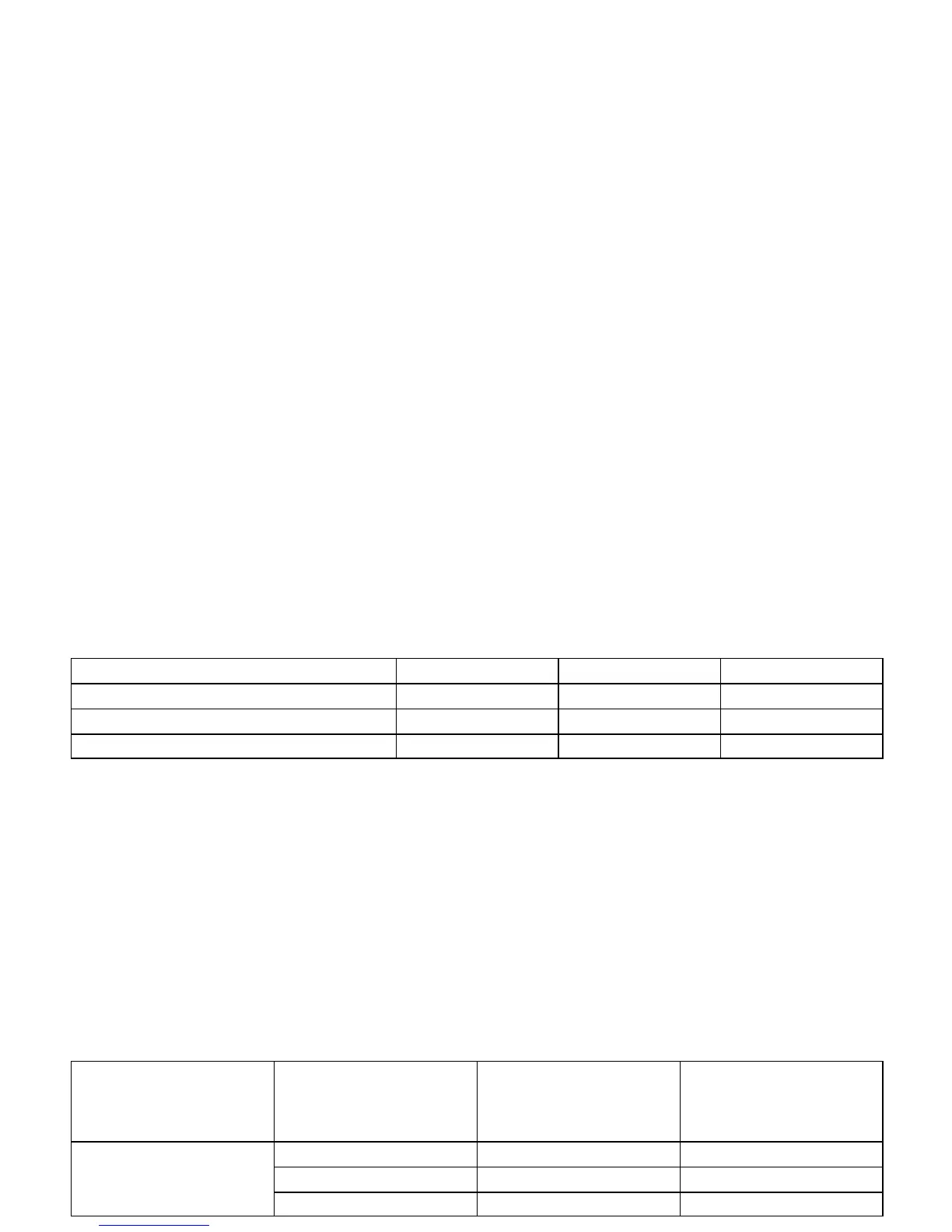

FASTENER TIGHTENING SPECIFICATIONS

Application NSm Lb–Ft Lb–In

Brake Lines 16 12 –

Master Cylinder Attaching Nuts 18 13 –

Proportioning Valves 22 16 –

DIAGNOSIS

CHECKING BRAKE

PROPORTIONING VALVE

Use two brake pressure gauges to check the brake pro-

portioning valves that are attached to the master cylinder

on non–ABS braking systems. These valves limit the out-

let pressure to the rear brakes after a predetermined mas-

ter cylinder pressure has been reached. (On ABS braking

systems, the hydraulic modulator/ motor pack assembly

controls the hydraulic pressure to both the rear wheel cyl-

inders or rear calipers, and the front calipers.)

When checking the brake proportioning valves, be sure

that the hydraulic line pressure is measured simulta-

neously and diagonally on the front and the rear axles. To

measure the pressure, use the following steps.

1. Remove the bleeder valve and install a pressure

gauge to one of the rear brake cylinders.

2. Install another bleeder valve and install another

pressure gauge to the diagonally opposite front

brake.

3. Build pressure by pressing firmly on the brake ped-

al several times. (The pressure indicated on the

gauge is not regulated and represents the actual

brake system hydraulic pressure.)

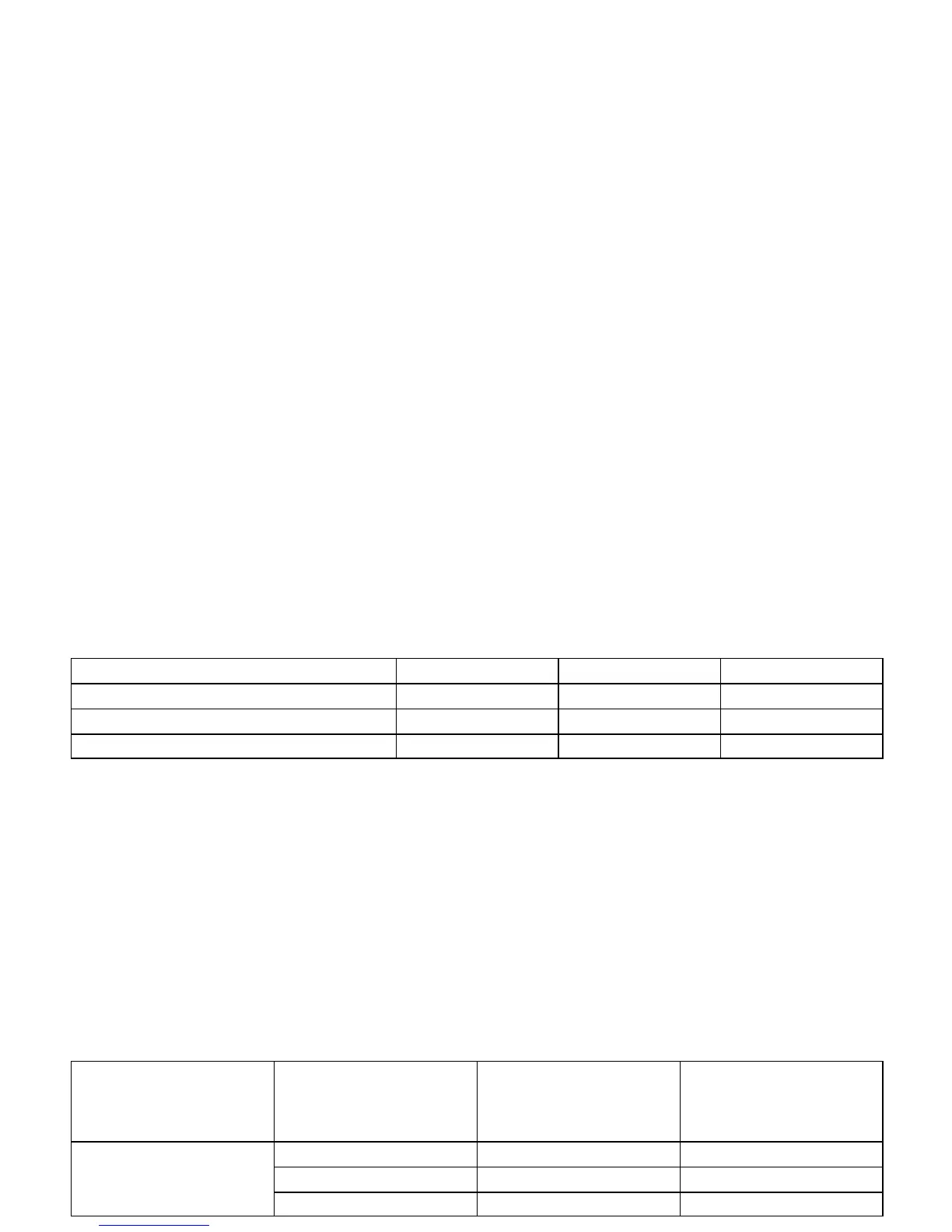

4. Build pressure until the test values in the following

proportioning valve test chart are achieved.

Engine Reference Number for

Gradient and Switching

Pressure on the Valve

Housing

Input Pressure Read on

the Manometer at the

Front Axle in kPa (psi)

Output Pressure Read

on the Manometer at the

Front Axle in kPa (psi)

2.0L 0.3/40 500 (73) 500 (73)

5 500 (798) 4 450 ± 200 (645 ± 29)

10 000 (1,450) 5 800 ± 300 (841 ± 44)

Loading...

Loading...