1A – 6IGENERAL ENGINE INFORMATION

DAEWOO V–121 BL4

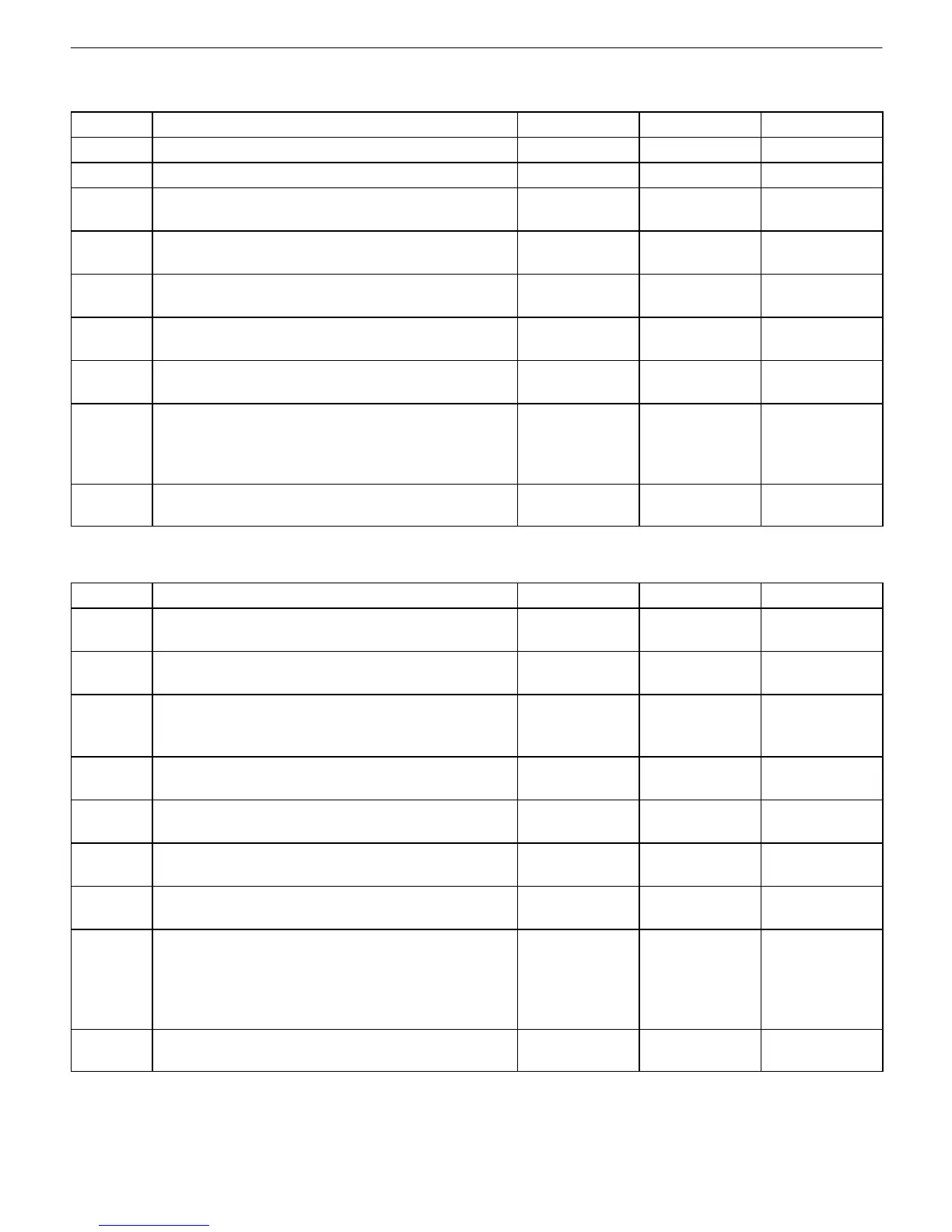

Light Knock Hot

Step Action Value(s) Yes No

1 Is there a light knock when the engine is hot? Go to Step 2 System OK

2 Is detonation or spark knock evident? Go to Step 3 Go to Step 4

3 Check the engine timing and the fuel quality.

Was the problem found?

Go to Step 1

4 Inspect the torque converter bolts.

Are the bolts loose?

45 NSm (33 lb–

ft)

Go to Step 5 Go to Step 6

5 Tighten the torque converter bolts.

Is the repair complete?

Go to Step 1

6 Inspect the manifold.

Is there an exhaust leak at the manifold?

Go to Step 7 Go to Step 8

7 Tighten the bolts or replace the gasket.

Is the repair complete?

Go to Step 1

8 Check the rod bearing clearance.

Is the clearance within the specified value?

0.019–0.070

mm

(0.0007–0.0027

in.)

Go to Step 9 System OK

9 Replace the rod bearings as necessary.

Is the repair complete?

Go to Step 1

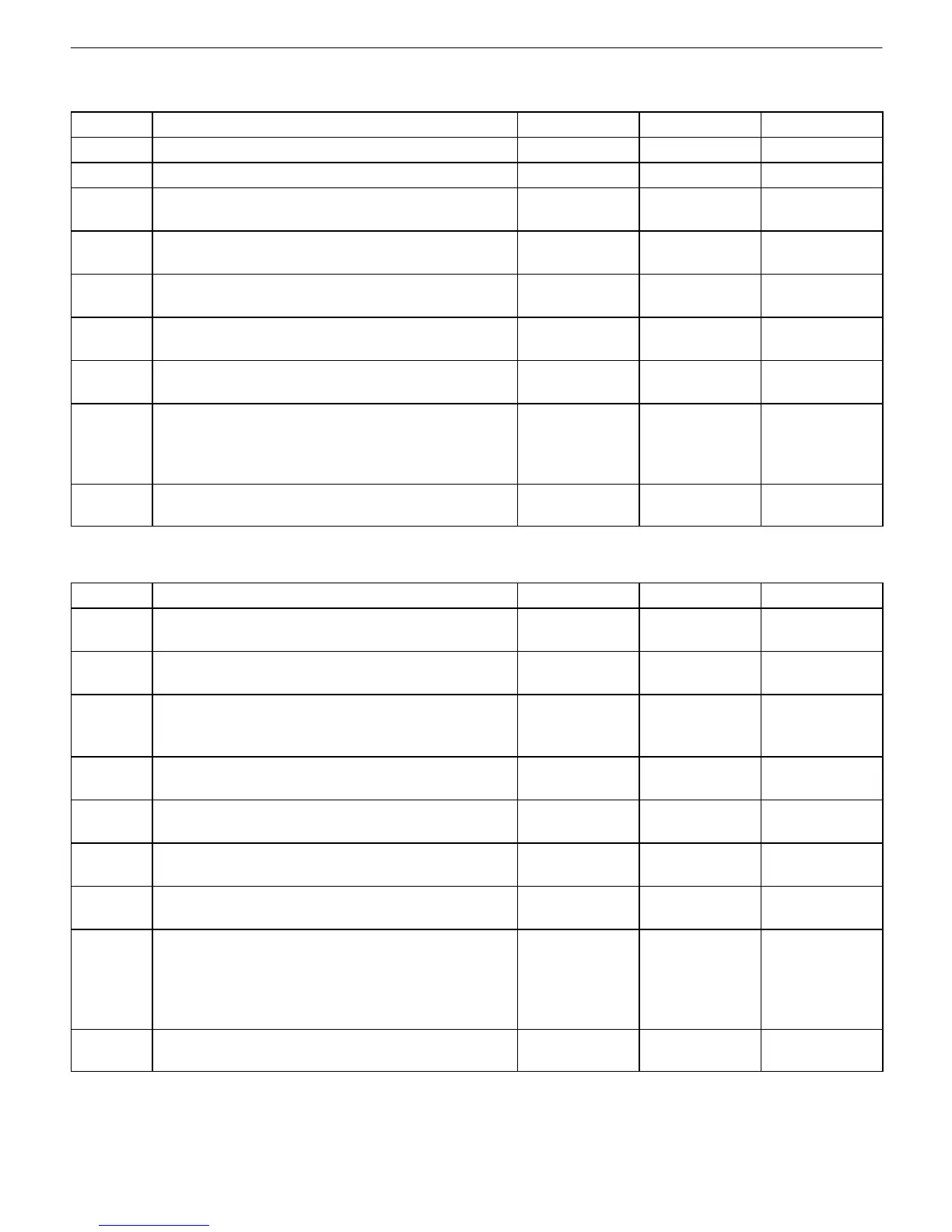

Knocks During Initial Start–Up But Lasts Only a Few Seconds

Step Action Value(s) Yes No

1 Does the engine knock during initial start–up but last

only a few seconds?

Go to Step 2 System OK

2 Check the engine oil.

Is the proper viscosity oil used in the crankcase?

Go to Step 4 Go to Step 3

3 Install oil of the proper viscosity for the expected

seasonal temperatures.

Is the repair complete?

Go to Step 1

4 Inspect the hydraulic lifters.

Is there evidence of hydraulic lifter bleed–down?

Go to Step 5 Go to Step 6

5 Clean, test and replace the lifters as necessary.

Is the repair complete?*

Go to Step 1

6 Inspect the crankshaft end clearance.

Is the clearance more than specified value?

0.01 mm

(0.0039 in.)

Go to Step 7 Go to Step 8

7 Replace the crankshaft thrust bearing.

Is the repair complete?

Go to Step 1

8 Inspect the front main bearing clearance.

Is the clearance more than the specified value?

2.0 DOHC

0.015–0.040

mm

(0.00059–0.001

5 in.)

Go to Step 9 System OK

9 Replace the worn parts of the front main bearing.

Is the repair complete?

Go to Step 1

* When the engine is stopped, some valves will be open. Spring pressure against the lifters will tend to bleed the lifter down.

Attempts to repair this should be made only if the problem is consistent.

An engine that is only operated for short periods between start–ups may have lifter noise that lasts for a few minutes. This

is a normal condition.

Loading...

Loading...