Description Page

Fuel Level Sensor Procedures

3 of 7

August, 2001

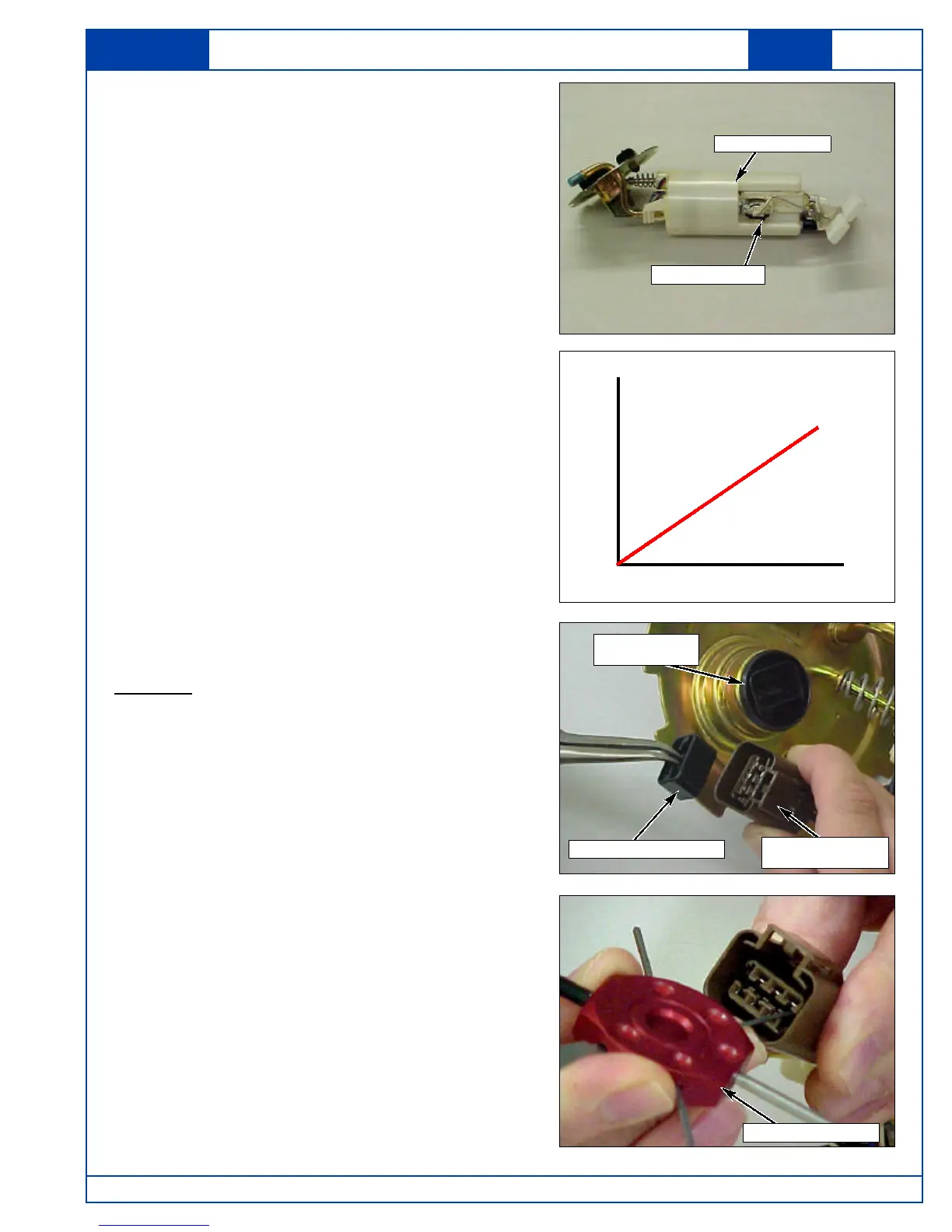

21.Slowly move the Fuel Level Sensor Float Arm

from the “empty” position to the “full” position

while observing the Fuel Level Sensor voltage

indications on the Scan Tool EVAP Data

Screen.

22.Confirm that the voltage makes a smooth

transition from 0.7 to 2.7 volts.

23.If the voltage "dips" or "spikes," at any point

throughout the voltage range, replace the Fuel

Level Sensor.

18.Reconnect the Wiring Harness Electrical

Connector to the Fuel Pump Module.

19.Turn the Ignition Switch to the "ON" position.

20.Connect the Scan 100 Scan Tool to the

vehicle Data-Link Connector (DLC) and go to

the EVAP Data Screen to view the Fuel Level

Sensor voltage

Screen Navigation Order:

Select “Diagnostic” 8 Choose “model year” 8

Choose “vehicle type” 8 Select “Powertrain”

8 Choose “transmission type” 8 Select “Data

Display” 8 Select “Engine Data” 8 Select

“EVAP Data”).

FUEL LEVEL SENSOR REPLACEMENT

PROCEDURE:

Removal

1. The Fuel Pump Module has a single (in-tank)

sub-harness that must be disconnected from

the Fuel Pump Module Mounting Flange

Connector.

2. Using a small pair of needle-nosed pliers,

remove and retain the secondary terminal lock

from the sub-harness electrical connector.

3. Using a suitable terminal release tool (similar to

Snap-on #YA500GM), depress the lock tang for

terminals 1 and 6, then pull the terminals out

through the back of the connector.

Note: The Fuel Level Sensor Terminals have

a beveled edge which requires proper

orientation when reinstalling in the

connector. Carefully note their

location by wire color in the connector

prior to removal.

Volts

EmptyFull

0.7

2.7

Note: Voltage sweep

should be steady with

no “dips” or “spikes”.

Fuel Level Sensor

Fuel Pump Module

Mounting Flange

Connector

Terminal Release Tool

Sub-Harness

Electrical Connector

Secondary Terminal Lock