September 2007

7-28 Advanced Programming

mA OUTPUT Option The mA Output submenu is used to individually enable or disable

error handling for fifteen different 4-20 mA analog output error

conditions. In addition, the type of response to the error may be

specified. To program this menu, see Figure C-9 on page C-9 and

proceed as follows:

• The DriftCal Offset Error is generated when an error occurs during

an offset gas (one-gas) calibration.

If the Enable option was selected above, one or both of the following

additional prompts appear. Otherwise, skip over these prompts.

If the Force to Value option was selected above, the following

additional prompt appears. At that prompt, values from 0.00 to 25.00

may be entered. A 0.00 value forces a 0-3 mA output signal, and a

25.00 value forces a 22-26 mA output signal.

• The above programming sequence is repeated for all other error

conditions in this submenu (see the Terminal submenu on pages

7-22 to 7-27 for a list and description of all available options). As

usual, press

[NO] to move between the options and press [YES] or

[ENTER] to program the displayed option.

When ready, you may exit this submenu at the Done? option, as

described in the Terminal submenu on the previous page.

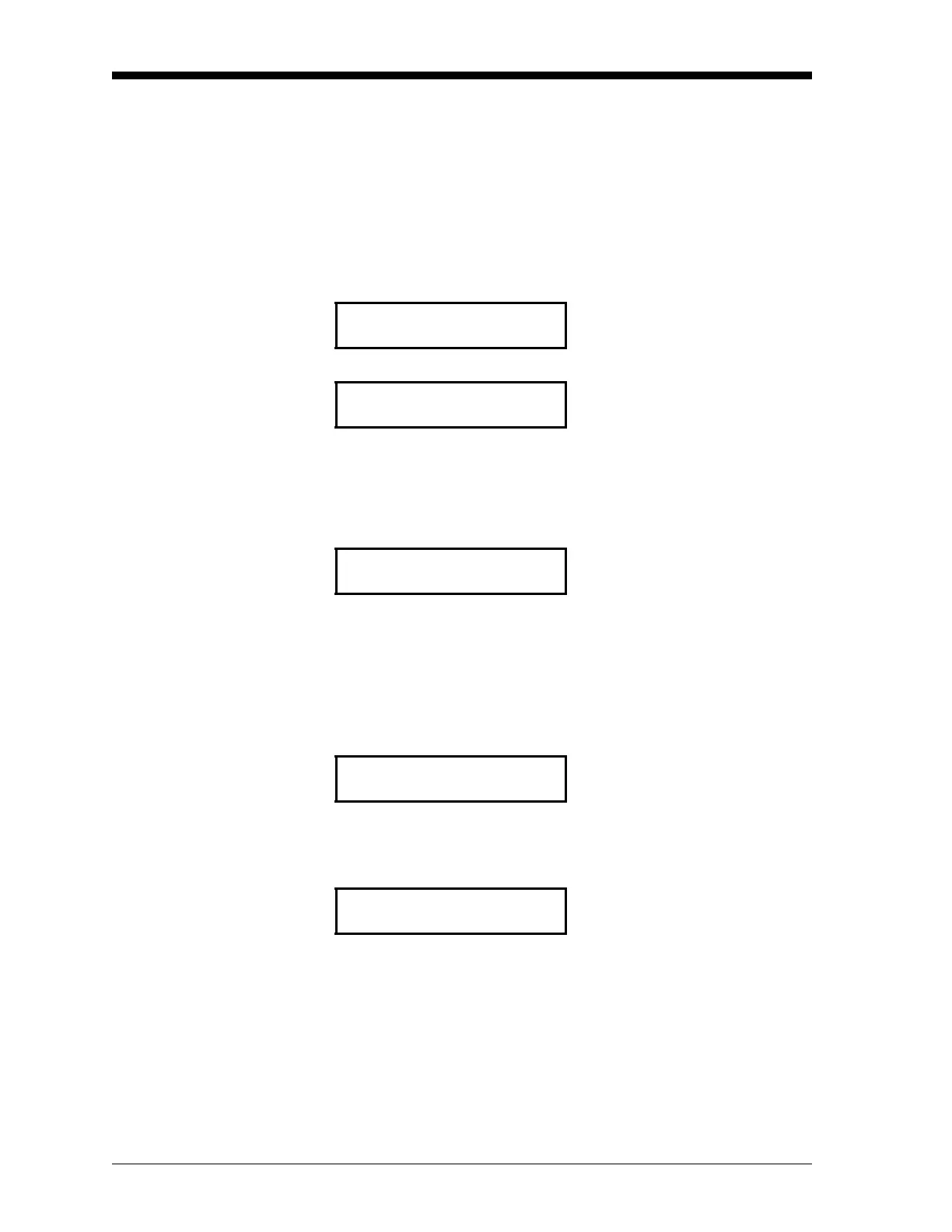

ENABLE/DISABLE ERRORS

Press [N] to skip this error, or

press

[Y] or [Enter] to set it.

DriftCal Offset Error?

DriftCal Offset Error response:

Press [N] to select the desired

option, then press

[Y] or [Enter] to

confirm your selection and move

to the next prompt.

disable [ENABLE]

Set mA Output Error response:

Press [N] to select the desired

option, then press

[Y] or [Enter] to

confirm your selection and move

to the next prompt.

[force high] force low force to value

Enter mA Output Error Value

To accept the current value, press

[Y] or [Enter]. To change the

current value, use the numeric

keys to enter a new value and

press

[Y] or [Enter] twice.

mA [xx.xx]

ENABLE/DISABLE ERRORS

Press [N] to move on to the next

error.

DriftCal Offset Error?

Loading...

Loading...