Do you have a question about the INVT Goodrive350 Series and is the answer not in the manual?

Emphasizes careful reading and adherence to safety precautions for installation, operation, and servicing to prevent injury or damage.

Defines Danger (serious injury/death), Warning (physical injury/equipment damage), and Note (procedures for proper operation).

Explains warning symbols (Danger, Warning, Forbid, Hot, Electric shock) used to caution about conditions and how to avoid them.

Provides crucial safety guidelines, including restrictions on qualified personnel, power disconnection before work, and avoiding modifications.

Details safety measures for delivery and installation, such as using fire-retardant materials, proper connections, and avoiding wet conditions.

Outlines safety practices during commissioning and running, including power disconnection, avoiding operations during running, and emergency stop device usage.

Specifies safety procedures for maintenance and component replacement, emphasizing power disconnection and anti-static measures.

Checks installation conditions after the inverter is properly installed, including power cables, peripheral accessories, and grounding.

Outlines procedures for basic commissioning before inverter operation, including motor parameter setup and autotuning.

Details the technical specifications of the inverter, including power input, power output, control performance, and peripherals.

Details requirements for the installation environment, including site conditions, ambient temperature, humidity, and running environment.

Illustrates wiring diagrams for main circuits of AC 3PH 380V and 660V inverters, including optional parts.

Presents the wiring diagram for the basic control circuit, detailing terminal functions and signal connections.

Details protective measures for preventing short-circuits and thermal overload in the inverter and motor circuits.

Details operations like entering/exiting menus, parameter selection, list modification, and parameter addition.

Provides a flowchart for common commissioning procedures, including motor parameter setup, autotuning, and running commands.

Details the motor parameter autotuning function, including its types and operational requirements.

Explains the theory and application of vector control for asynchronous motors and permanent-magnet synchronous motors.

Explains PID control principles, working modes, and general procedures for PID parameter setup and fine-tuning.

Categorizes function parameters by group (e.g., Basic functions, Start/stop control, Vector control) for easy reference.

Covers start/stop control parameters including running mode, DC brake settings, stop mode, and protection selections.

Defines parameters for vector control of Motor 1, including speed loop, current loop, and torque control settings.

Explains PID control parameters, including reference source, feedback source, output characteristics, and gain settings.

Covers parameters for Simple PLC and multi-step speed control, including modes, memory selection, and step settings.

Details protection parameters such as phase loss, overvoltage stall, current limit, and overload/underload pre-alarm.

Defines parameters for position control, such as mode selection, command source, gains, and limits.

Details parameters for spindle positioning, including mode selection, zeroing, scale division, and rigid tapping.

Describes methods for resetting inverter faults using the STOP/RST key, digital inputs, or power cycle.

Provides a systematic approach to process faults, including confirming keypad display, checking parameters, and ruling out causes.

Lists common fault codes, possible causes, and corrective measures for inverter faults like OUt1, OUt2, OUt3, OV1, OV2, etc.

Provides flowcharts for analyzing common faults such as motor fails to work, motor vibrates, overvoltage, undervoltage, and overheating.

Covers Modbus RTU command codes (03H for reading, 06H for writing, 08H for diagnosis, 10H for continuous writing) and data formats.

Lists common communication faults like no response or exception response and their possible causes.

Details the EC-PC501-00 programmable extension card, its features, programming capabilities, and terminal functions.

Specifies requirements for adding fuses, MCCBs, and electromagnetic contactors for overload protection and main circuit control.

Details brake component selection, including built-in and external brake units, resistors, and cable selection.

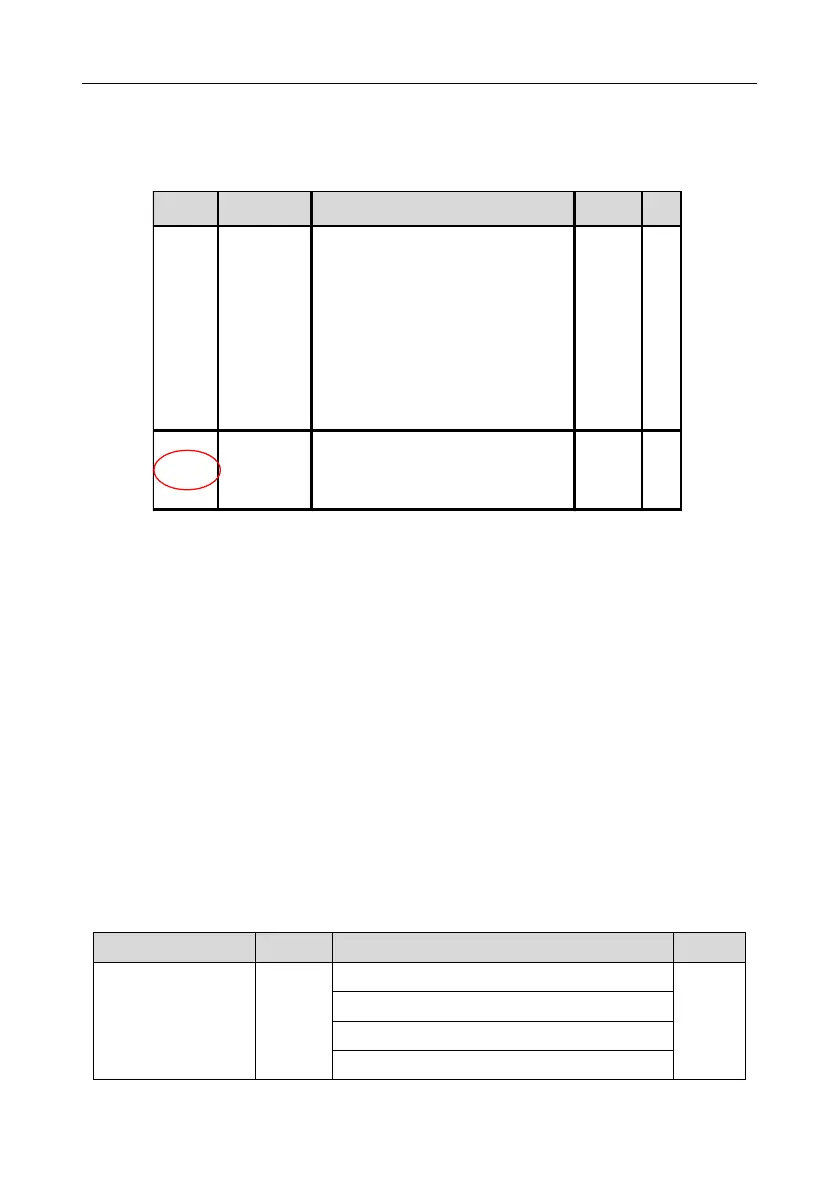

Describes the input states (H1/H2) and their corresponding faults (Safe Torque Off, Channel exceptions) for the STO function.

Provides trigger and indication delay times for STO modes (STL1, STL2, STL3, STO).

Offers a checklist to ensure the STO function is properly used before installation, covering drive run/stop, circuit connections, and testing.