Rev. 2.0

Maintenance Guide

2-10

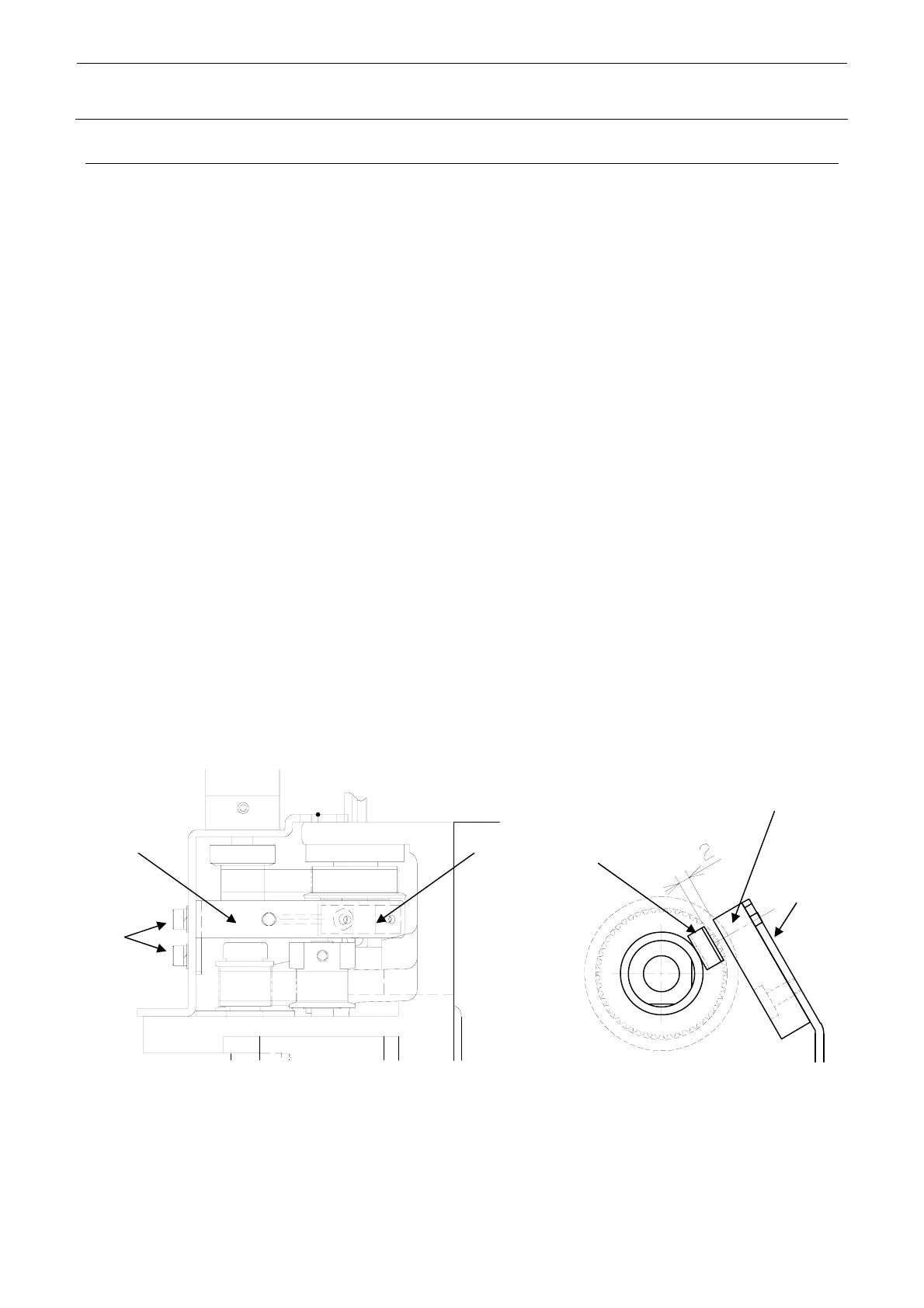

2-3. Replacing the T-Sensor

After the T-sensor has been replaced, perform the home position return to check that it functions

correctly. (For details about input items, see section 2-8.)

1) Detach the T-sensor bracket from the head.

2) Remove the mounting screws d (2 pcs.) of the T-sensor bracket and detach the bracket.

3) Cut the tie-up band securing the T-sensor cables.

4) Remove the T-sensor e from the bracket and replace it.

5) Reassemble the components in the reverse order of disassembly.

∗ Apply Loctite 242 to the mounting screws e and tighten them with a tightening torque of

0.14 N⋅m.

∗ Make the adjustment so that the end face of the motor shaft is aligned with the end face of

the pulley, and then fix the setscrews of the T-pulley.

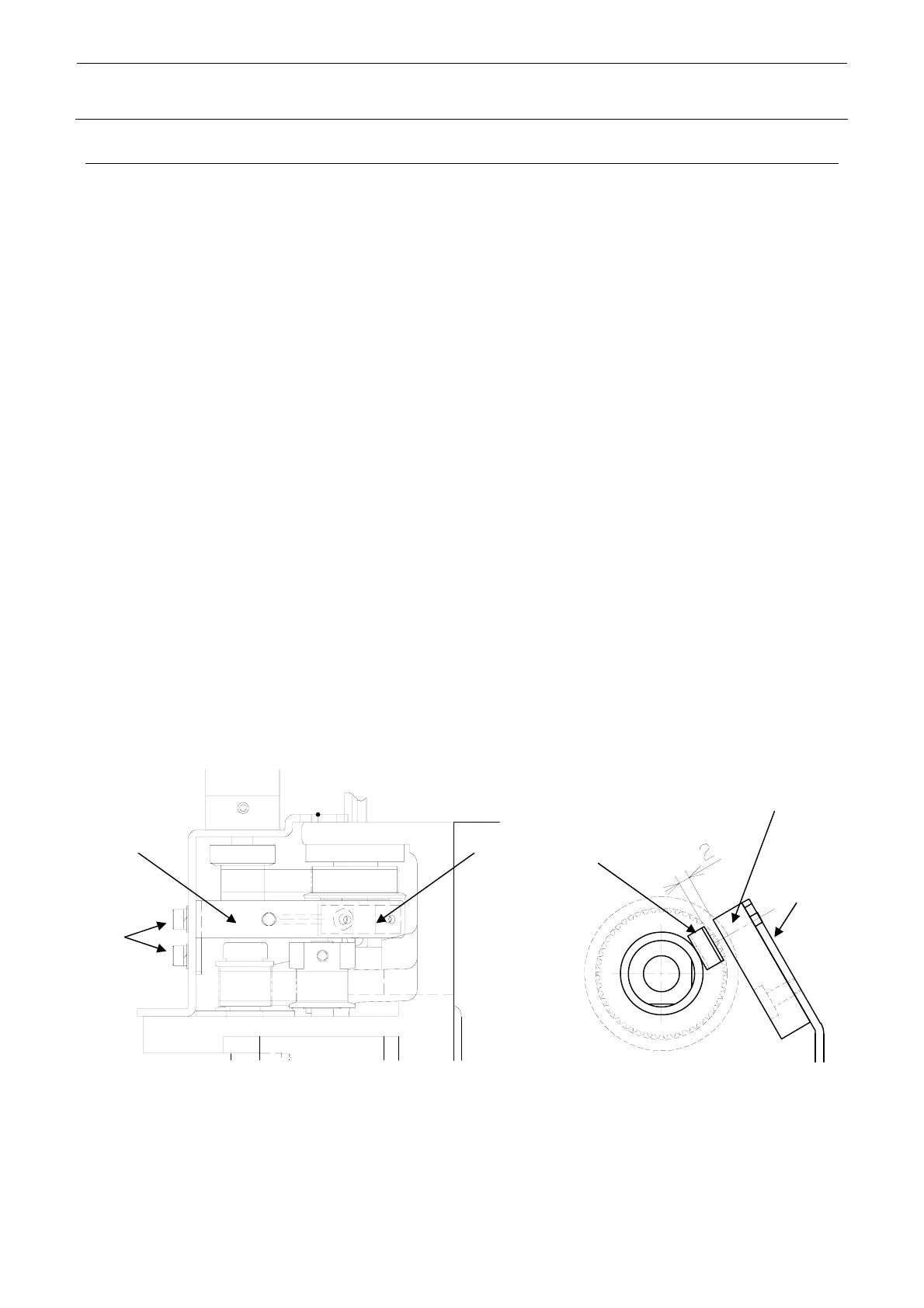

6) Check following the procedure below and make adjustments if necessary.

<Procedure>

c Make the adjustment so that the clearance between the T-sensor e and T-sensor dog f is 2

mm or less and that the T-sensor is not in contact with other part around it, such as pulley.

d Manually rotate the θ-axis to make sure that the T-sensor is not in contact with the T-sensor

dog.

e Put the servo in the free status with the power to the machine turned ON and manually rotate

the θ-axis to make sure that the sensor is turned ON or OFF if the sensor gets close to the

dog.

d

c

e

e

f

c

Figure 2-3-1

Loading...

Loading...