Rev. 2.0

Maintenance Guide

5-3

5-3. Replacing the IN and OUT Motors

1) Disconnect the connector of the motor relay cable.

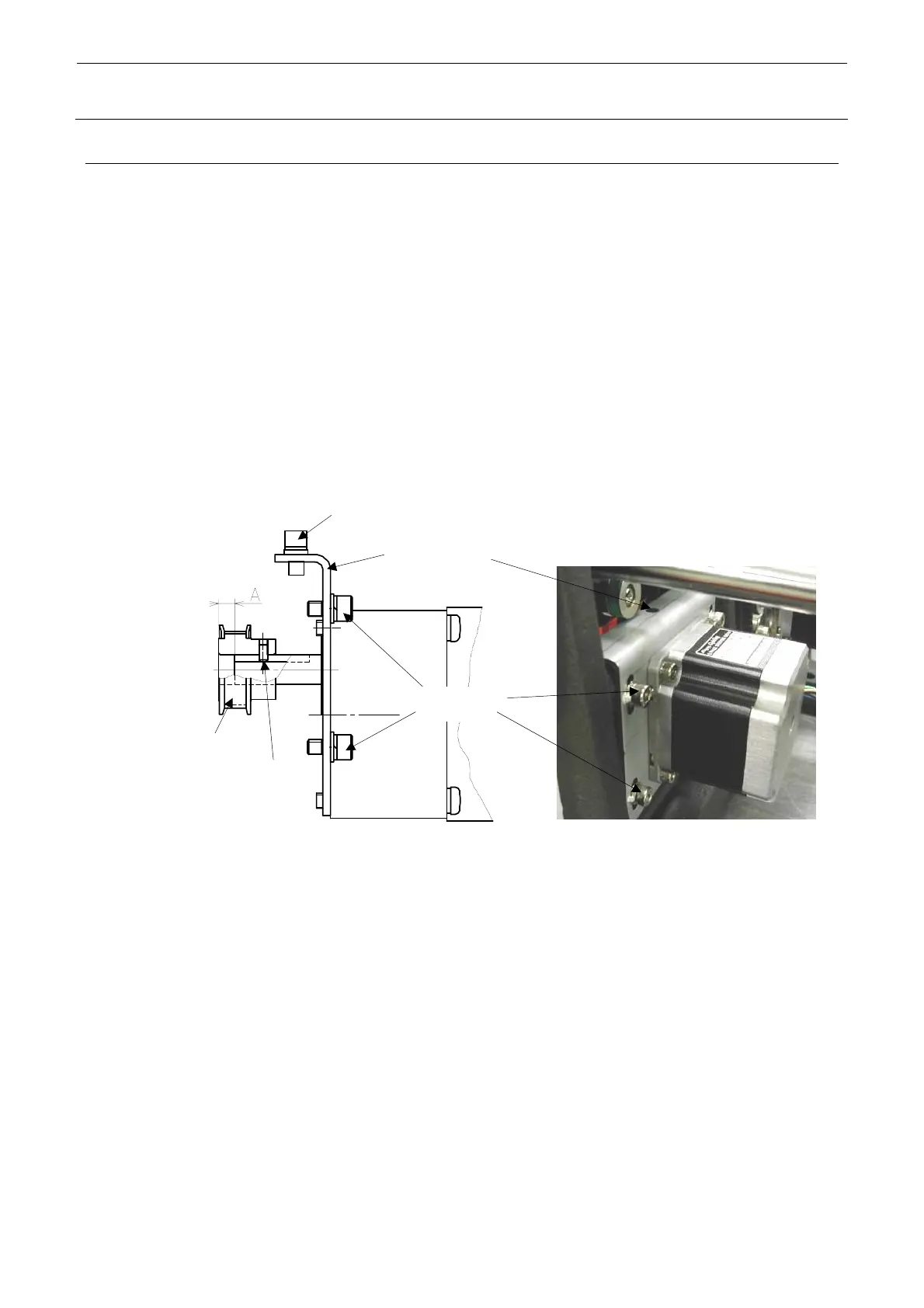

2) Loosen the screws fixing the motor bracket A to detach the drive belt from the motor pulley S.

3) Loosen the fixing screws d and detach the motor.

4) Make the end face of the motor shaft of a new motor aligned with the motor pulley S (A=0)

and tighten the fixing screw d.

5) Temporarily tighten the setscrews c and adjust the tension of the timing belt to 12N to 16N

by turning the setscrew e.

For this adjustment, use UNITTA’s acoustic belt tension meter (Weight = 2.5, Width = 6.0,

Span = 75).

6) After the belt tension has been adjusted, tighten the screws c to fix the motors to the rail

stand.

Fixin

screw d

Setscrew c

Motor pulley S

Motor bracket A

Setscrew e

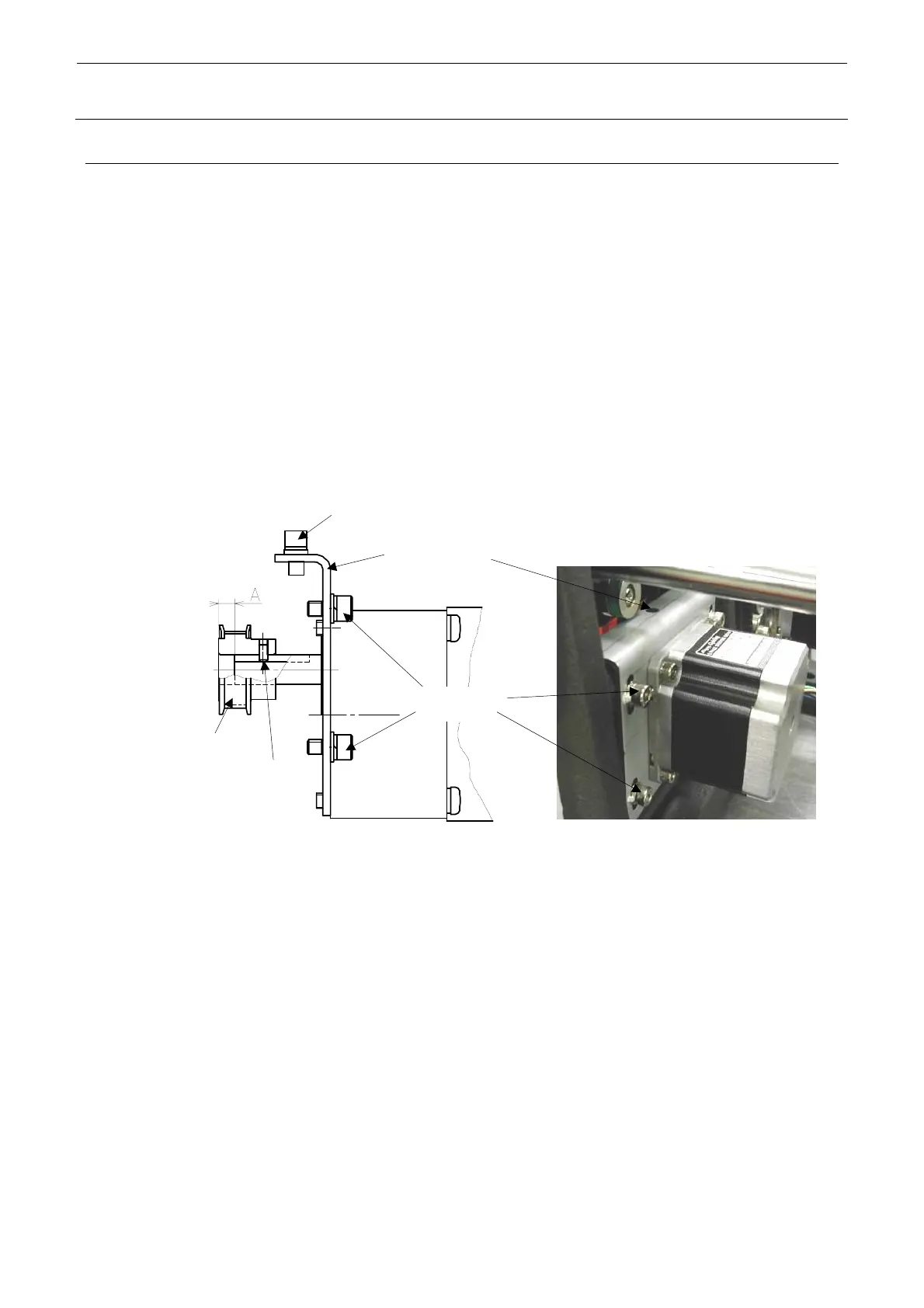

Figure 5-3

Note) Belt (tension) is stretched excessively. → Torque of the drive shaft increases.

Note) Belt (tension) is loosened excessively. → Teeth on the timing pulley are skipped.

(Noise is produced.)

Loading...

Loading...