Rev. 2.0

Maintenance Guide

5-23

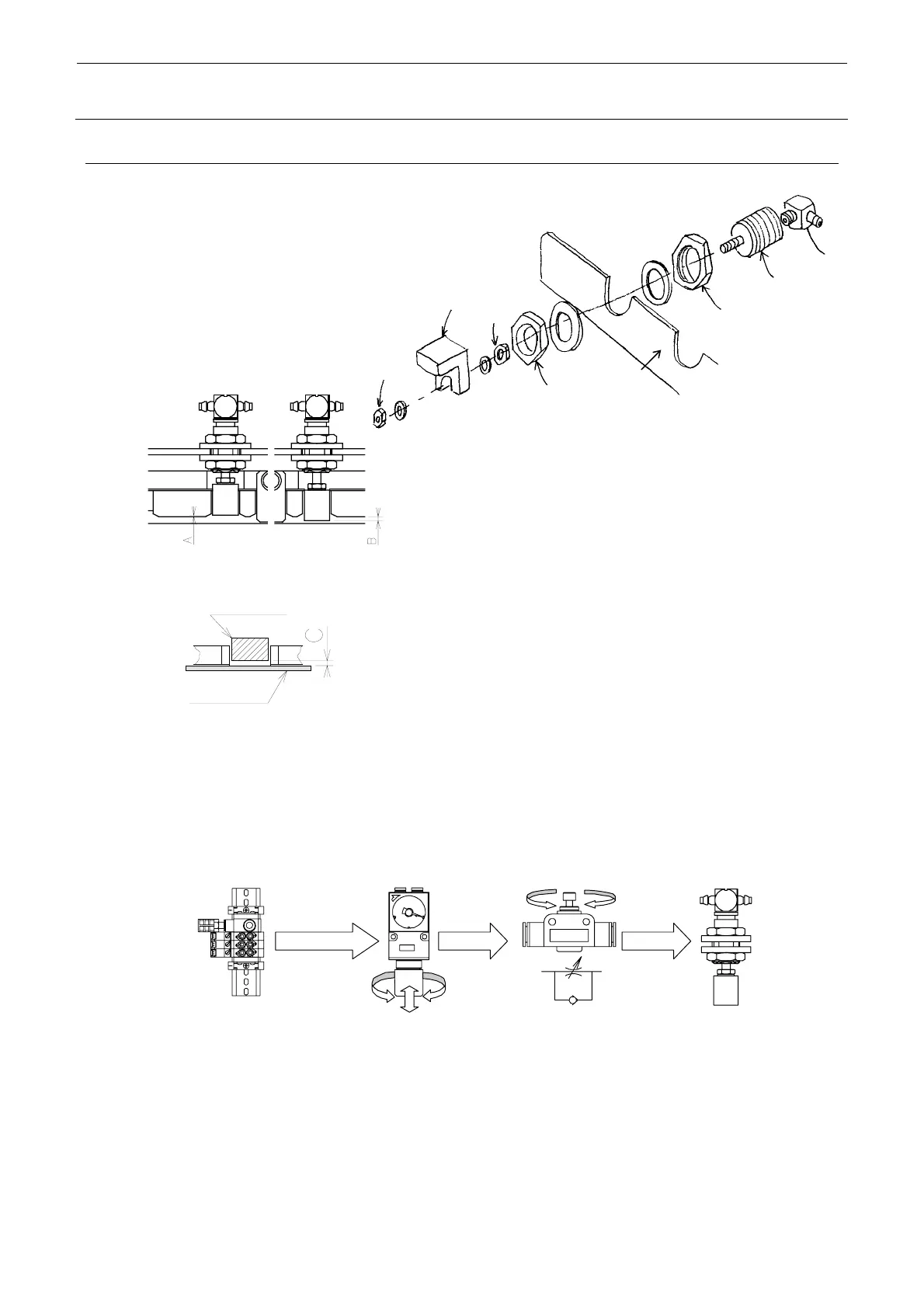

5-11. Replacing the Pusher Y Cylinder (Outer Shape Reference)

1) Detach the par d or e from

the cylinder c.

2) Loosen the nut (accessory) of

the cylinder c to detach it from

the part f.

3) Loosen the nut h(accessory)

to detach the pusher B g from

the top of the cylinder c.

4) Reassemble the components in the reverse

order of steps 1) to 3). When installing a

new pusher Y cylinder, check and adjust as

described below.

c Adjust so that the distance B is 1.5 mm

± 0.1mm when the Y pusher is ON

(extruded) and distance A is -0.5 mm ±

0.1mm when the Y pusher is OFF (not

extruded).

(See Figure 5-11-2.)

d

djust so that the gap C between the Y

pusher and transport belt is 0.2 mm

minimum.

Figure 5-11-2

Y

ushe

Transport belt

Figure 5-11-3

h

h

g

e

e

d

c

Figure 5-11-1

f

After the cylinder components have been assembled, supply the air (0.5 MPa) to check that

the cylinder moves smoothly.

e Adjust so that the pressure reducing valve is 0.5 MPa and the speed controller is opened

two turns from the fully closed position.

Solenoid valve

Pressure reducing valve:

0.5 Mpa

Speed controller:

Opened two turns from the fully

closed position

(Must be fixed with the lock nut.)

Y pusher

Figure 5-11-4

f After the components have been reassembled, supply air (0.5 MPa) and check that the

pusher operates smoothly when the air is turned ON and OFF.