3MNGINE -

WORK

ON

THE

INDIVIDUAL

PARTS

118

Workinl

on

the

rilht

section

of

tbe

enline

case

-

Remove

the oil pressure regulator valve. (

or

p.

121)

-

Remove

all remaining dowels.

-

Remove

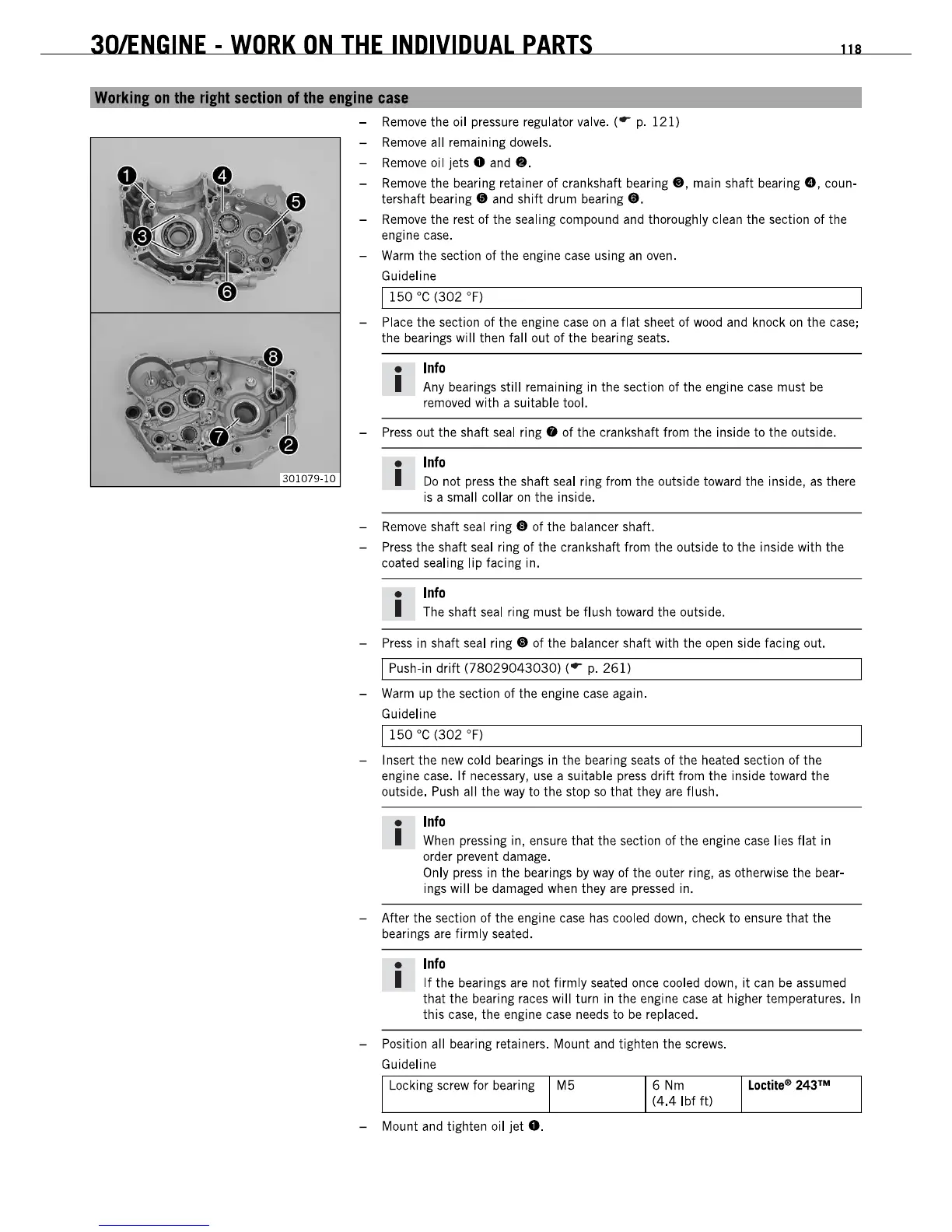

oil jets 0 and

•.

-

Remove

the bearing retainer of crankshaft bearing., main shaft bearing

.,

coun-

tershaft

bearing.

and

shift

drum

bearing

•.

-

Remove

the rest

of

the sealing compound and thoroughly clean the section of the

engine

case.

- Warm the section

of

the engine case using

an

oven.

Guideline

1150

°C

(302

oF)

- Place the section of the engine

case

on

a flat sheet of

wood

and knock

on

the

case;

the bearings will then fall out of the bearing seats.

•

Info

I Any bearings still remaining in the section

of

the engine case must

be

removed with a suitable tool.

-

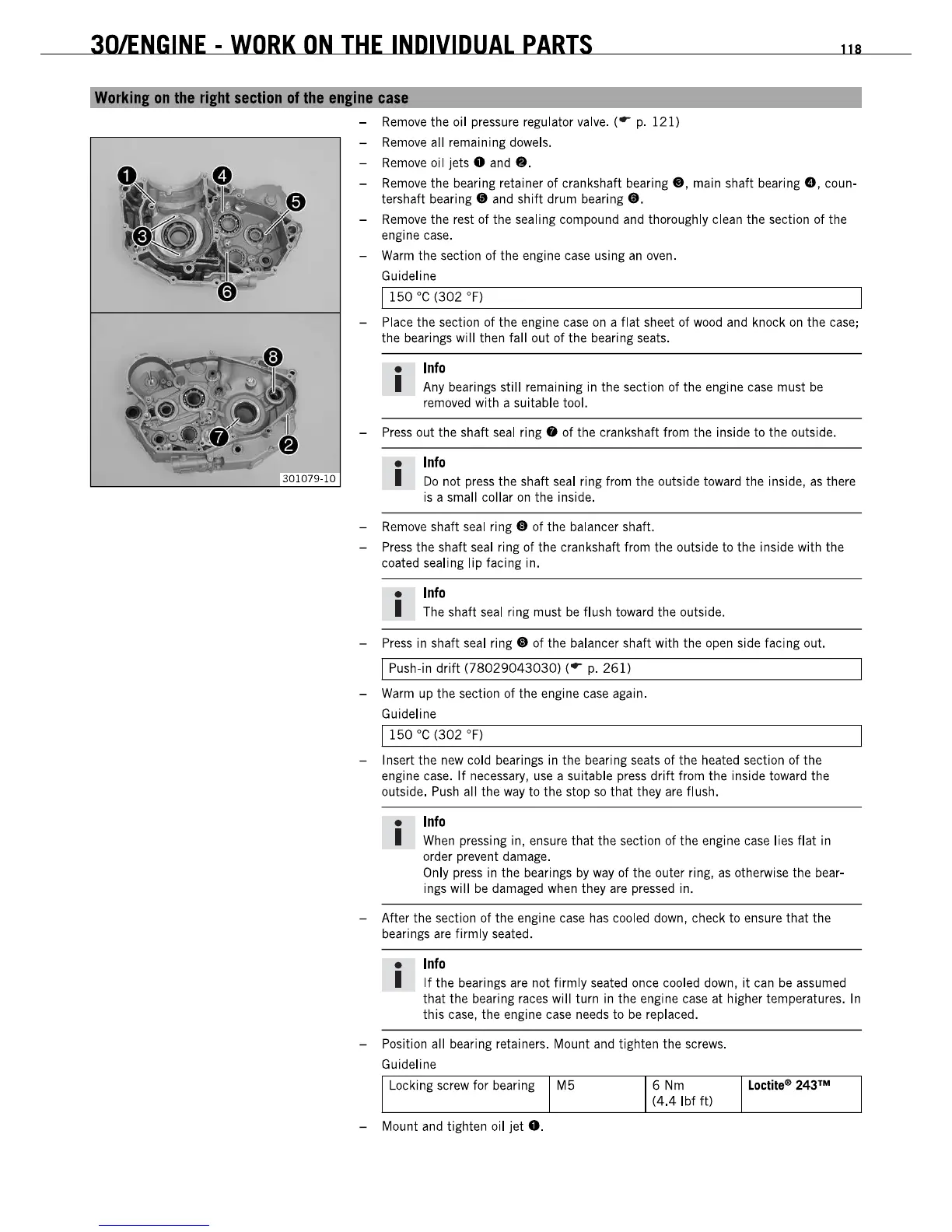

Press

out the shaft seal

ring.

of the crankshaft from the inside

to

the outside.

•

Info

I

Do

not press the shaft seal ring from the outside toward the inside,

as

there

is

a small collar

on

the inside.

-

Remove

shaft seal

ring.

of the balancer shafl.

-

Press

the shaft seal ring of the crankshaft from the outside

to

the inside with the

coated sealing lip facing in.

•

Info

I The shaft seal ring must be flush toward the outside.

-

Press

in shaft

seal

ring.

of the balancer shaft with the

open

side facing oul.

1 Push-in

drift

(78029043030)

(

or

p.

261)

- Warm up the section of the engine case again.

Guideline

1150

°C

(302

OF)

- Insert the

new

cold bearings in the bearing seats of the heated section of the

engine case.

If

necessary,

use

a suitable

press

drift

from the inside toward the

outside.

Push

all the way to the stop

so

that they are flush.

•

Info

I

When

pressing in, ensure that the section

of

the engine case lies flat in

order prevent damage.

Dnly press in the bearings

by

way

of

the outer ring,

as

otherwise the bear-

ings will

be

damaged when they

are

pressed

in.

- After the section of the engine case

has

cooled down, check

to

ensure that the

bearings

are

firmly seated.

•

Info

I

If

the bearings are not firmly seated once cooled down,

it

can

be

assumed

that the bearing races will turn in the engine

case

at higher temperatures.

In

this

case,

the engine

case

needs

to

be replaced.

- Position all bearing retainers. Mount

and

tighten the screws.

Guideline

Locking screw for bearing M5 6

Nm

(4.4

Ibf ft)

- Mount and tighten oil jet

•.

3MNGINE -

WORK

ON

THE

INDIVIDUAL

PARTS

118

Workinl

on

the

rilht

section

of

tbe

enline

case

-

Remove

the oil pressure regulator valve. (

or

p.

121)

-

Remove

all remaining dowels.

-

Remove

oil jets 0 and

•.

-

Remove

the bearing retainer of crankshaft bearing., main shaft bearing

.,

coun-

tershaft

bearing.

and

shift

drum

bearing

•.

-

Remove

the rest

of

the sealing compound and thoroughly clean the section of the

engine

case.

- Warm the section

of

the engine case using

an

oven.

Guideline

1150

°C

(302

oF)

- Place the section of the engine

case

on

a flat sheet of

wood

and knock

on

the

case;

the bearings will then fall out of the bearing seats.

•

Info

I Any bearings still remaining in the section

of

the engine case must

be

removed with a suitable tool.

-

Press

out the shaft seal

ring.

of the crankshaft from the inside

to

the outside.

•

Info

I

Do

not press the shaft seal ring from the outside toward the inside,

as

there

is

a small collar

on

the inside.

-

Remove

shaft seal

ring.

of the balancer shafl.

-

Press

the shaft seal ring of the crankshaft from the outside

to

the inside with the

coated sealing lip facing in.

•

Info

I The shaft seal ring must be flush toward the outside.

-

Press

in shaft

seal

ring.

of the balancer shaft with the

open

side facing oul.

1 Push-in

drift

(78029043030)

(

or

p.

261)

- Warm up the section of the engine case again.

Guideline

1150

°C

(302

OF)

- Insert the

new

cold bearings in the bearing seats of the heated section of the

engine case.

If

necessary,

use

a suitable

press

drift

from the inside toward the

outside.

Push

all the way to the stop

so

that they are flush.

•

Info

I

When

pressing in, ensure that the section

of

the engine case lies flat in

order prevent damage.

Dnly press in the bearings

by

way

of

the outer ring,

as

otherwise the bear-

ings will

be

damaged when they

are

pressed

in.

- After the section of the engine case

has

cooled down, check

to

ensure that the

bearings

are

firmly seated.

•

Info

I

If

the bearings are not firmly seated once cooled down,

it

can

be

assumed

that the bearing races will turn in the engine

case

at higher temperatures.

In

this

case,

the engine

case

needs

to

be replaced.

- Position all bearing retainers. Mount

and

tighten the screws.

Guideline

Locking screw for bearing M5 6

Nm

(4.4

Ibf ft)

- Mount and tighten oil jet

•.

Loading...

Loading...