04LSHOCK

ABSORBER,

SWINGARM

56

Bleadinl

and

fillinl

the

damller

• Info

Alternative 2

Warning

Danler of accidents Modifications

to

the suspension settings

can

seri-

ously alter the vehicle's ride behavior.

- Extreme modifications to the adjustment of the spring elements can

cause a serious deterioration in the handling characteristics and

overload some components.

- Only make adjustments within the recommended range.

- After making adjustments, ride slowly at first

to

get the feel of the

new ride behavior.

- Mount adjusting screws

e,

•

and.

in the positions determined when disas-

sembling.

I Before working with the vacuum pump, carefully

read

the vacuum pump operating manual.

Completely open the adjusters of the rebound and compression damping.

"

•

200782-10

-

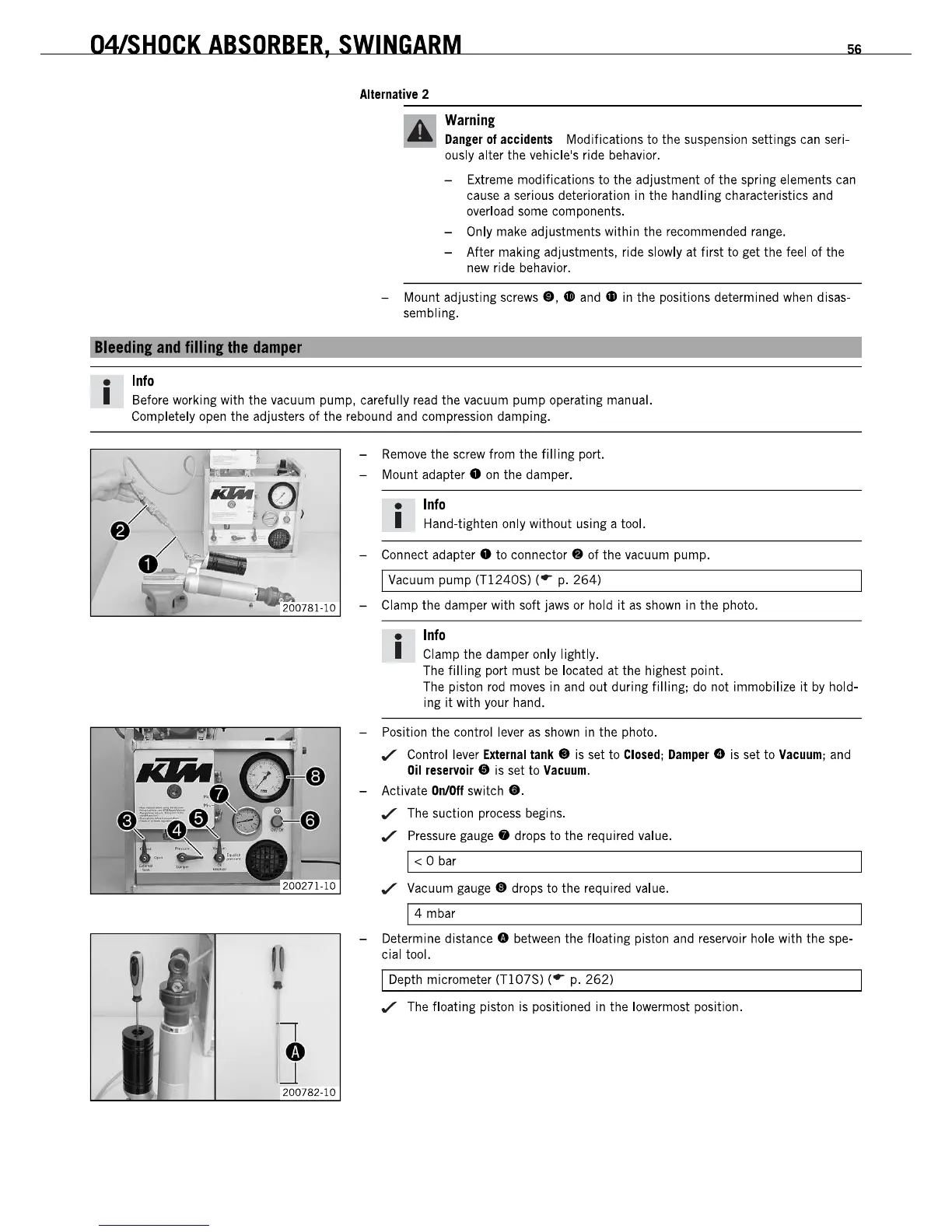

Remove

the screw from the

filling

port.

- Mount adapter 0

on

the damper.

• Info

I Hand-tighten only without using a tool.

- Connect

adapter.

to

connector.

of the vacuum pump.

1 Vacuum pump (Tl240S) (r

p.

264)

- Clamp the damper with soft jaws or hold

it

as

shown in the photo.

• Info

I Clamp the damper only lightly.

The

filling

port must

be

located at the highest point.

The piston

rod

moves

in and out during filling;

do

not immobilize

it

by

hold-

ing

it

with your hand.

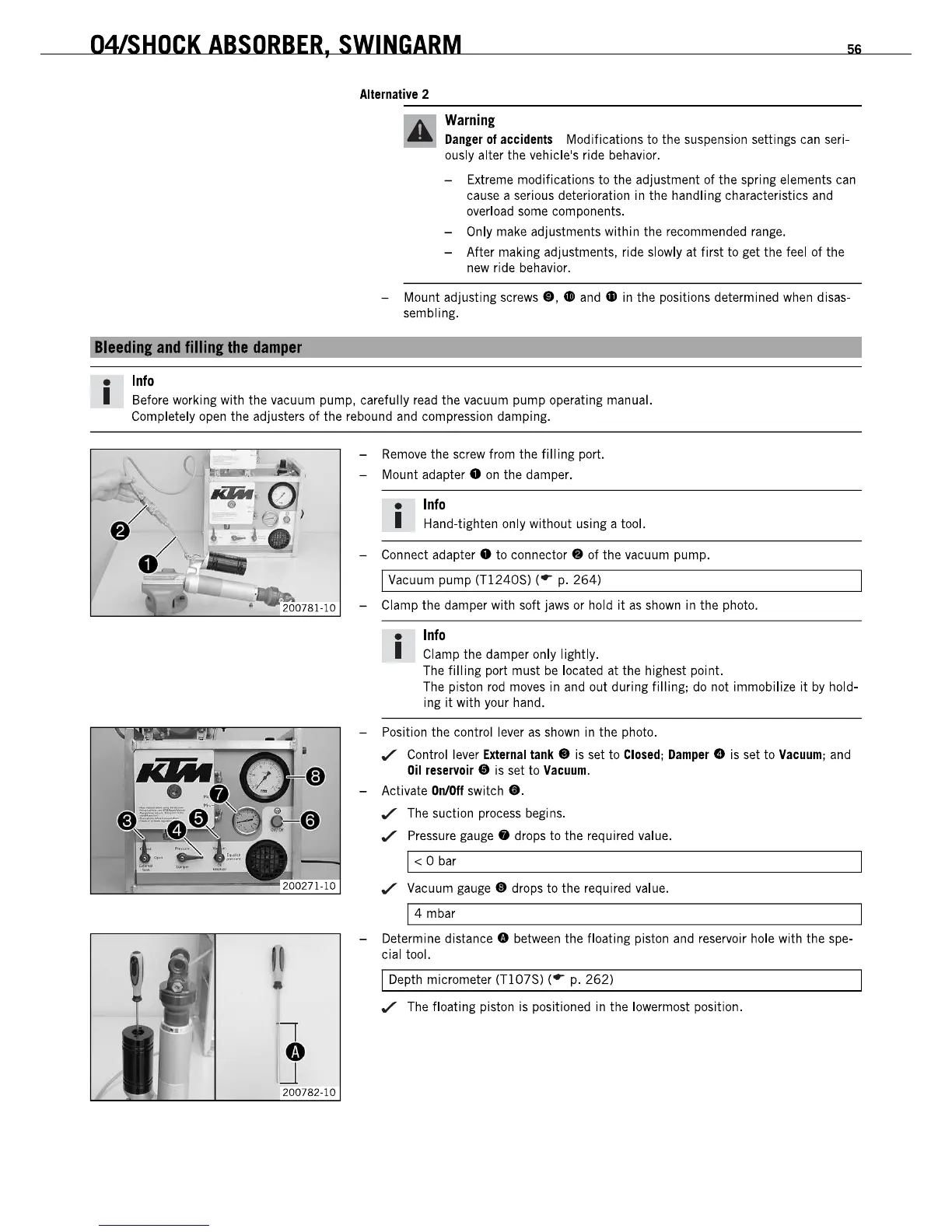

- Position the control lever

as

shown in the photo.

,/

Control lever

External

tank.

is set

to

Closed;

Damper

0 is set

to

Vacuum;

and

Oil

reservoir.

is set

to

Vacuum.

- Activate

OnIDff

switch

•.

,/

The suction process begins.

,/

Pressure

gauge.

drops

to

the required value.

1 < 0 bar

,/

Vacuum

gauge.

drops

to

the required value.

14

mbar

- Determine

distance.

between the floating piston and reservoir hole with the spe-

ciallool.

1 Depth micrometer (Tl07S) (r

p.

262)

,/

The floating piston is positioned in the lowermost position.

04LSHOCK

ABSORBER,

SWINGARM

56

Bleadinl

and

fillinl

the

damller

• Info

Alternative 2

Warning

Danler of accidents Modifications

to

the suspension settings

can

seri-

ously alter the vehicle's ride behavior.

- Extreme modifications to the adjustment of the spring elements can

cause a serious deterioration in the handling characteristics and

overload some components.

- Only make adjustments within the recommended range.

- After making adjustments, ride slowly at first

to

get the feel of the

new ride behavior.

- Mount adjusting screws

e,

•

and.

in the positions determined when disas-

sembling.

I Before working with the vacuum pump, carefully

read

the vacuum pump operating manual.

Completely open the adjusters of the rebound and compression damping.

"

•

200782-10

-

Remove

the screw from the

filling

port.

- Mount adapter 0

on

the damper.

• Info

I Hand-tighten only without using a tool.

- Connect

adapter.

to

connector.

of the vacuum pump.

1 Vacuum pump (Tl240S) (r

p.

264)

- Clamp the damper with soft jaws or hold

it

as

shown in the photo.

• Info

I Clamp the damper only lightly.

The

filling

port must

be

located at the highest point.

The piston

rod

moves

in and out during filling;

do

not immobilize

it

by

hold-

ing

it

with your hand.

- Position the control lever

as

shown in the photo.

,/

Control lever

External

tank.

is set

to

Closed;

Damper

0 is set

to

Vacuum;

and

Oil

reservoir.

is set

to

Vacuum.

- Activate

OnIDff

switch

•.

,/

The suction process begins.

,/

Pressure

gauge.

drops

to

the required value.

1 < 0 bar

,/

Vacuum

gauge.

drops

to

the required value.

14

mbar

- Determine

distance.

between the floating piston and reservoir hole with the spe-

ciallool.

1 Depth micrometer (Tl07S) (r

p.

262)

,/

The floating piston is positioned in the lowermost position.

Loading...

Loading...