301ENGINE

-

WORK

ON

THE

INDIVIDUAL

PARTS

128

Piston/cYlinder

-

deterrnininllhe

mounti!!l

clearance

- Check/measure the cylinder. (r

p.

126)

- Check/measure the piston. (r

p.

127)

- The smallest piston/cylinder mounting clearance equals the smallest cylinder bore diameter minus the largest piston diameter. The

largest piston/cylinder mounting clearance equals the largest cylinder bore diameter minus the smallest piston diameter.

Guideline

Piston/cylinder - mounting clearance

Size I

0.040

...

0.082

mm

(0.00157

...

0.00323

in)

Size

II

0.043

...

0.085

mm

(0.00169

...

0.00335

in)

Wear

limit

0.120

mm

(0.00472

in)

Chackinl

tha

oil

pum~

•

Info

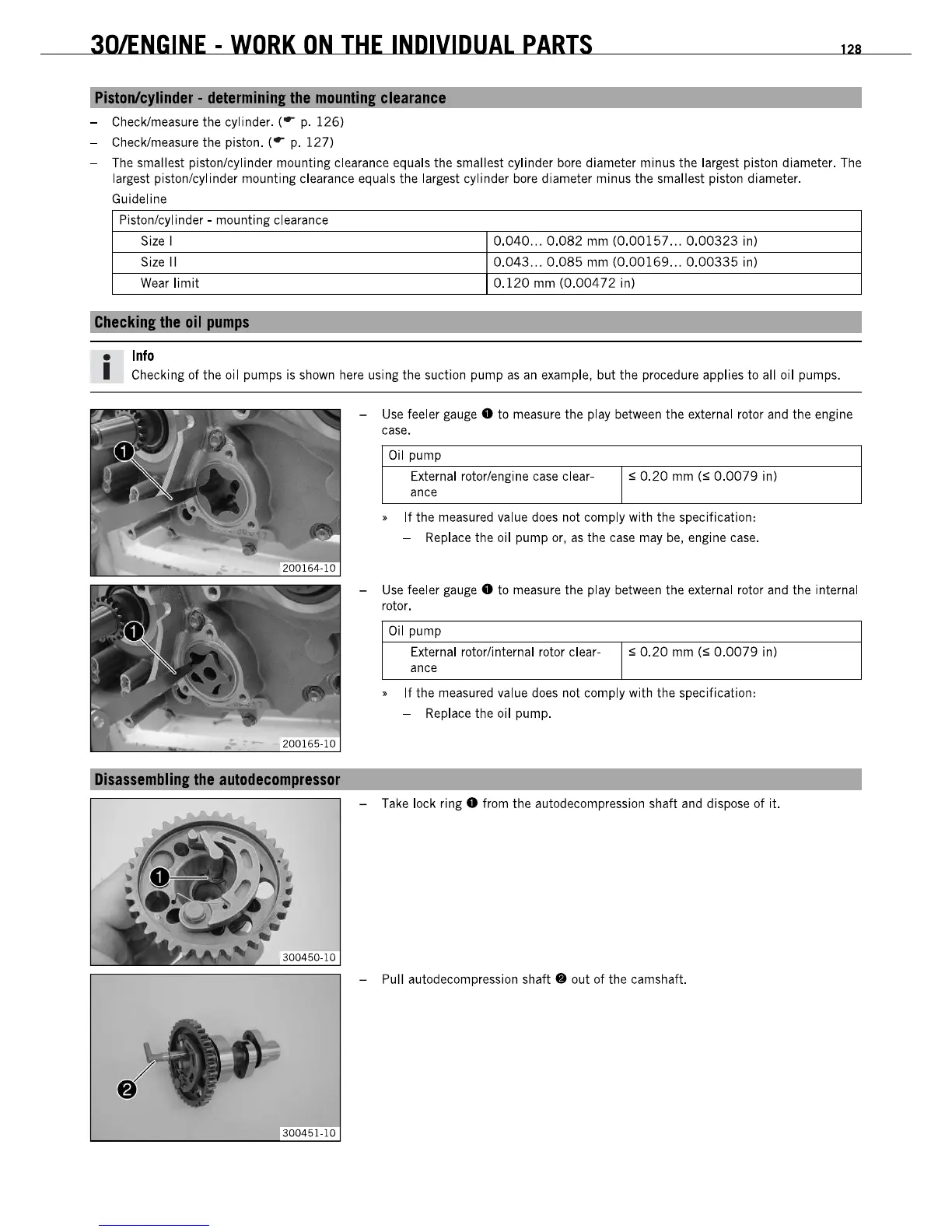

I Checking of the oil pumps is shown here using the suction pump

as

an

example, but the procedure applies

to

all oil pumps.

Disassamblinllha

autodacomprassor

30045\-10

-

Use

feeler

gauge.

to measure the play between the external rotor and the engine

case.

Oil pump

External rotor/engine case clear-

ance

I S

0.20

mm

(S

0.0079

in)

•

If

the measured value does not comply with the specification:

- Replace the oil pump

or,

as

the case may

be,

engine

case.

-

Use

feeler

gauge.

to measure the play between the external rotor and the internal

rotor.

Oil pump

External rotor/internal rotor clear-

I S

0.20

mm

(S

0.0079

in)

ance

•

If

the measured value does not comply with the specification:

- Replace the oil pump.

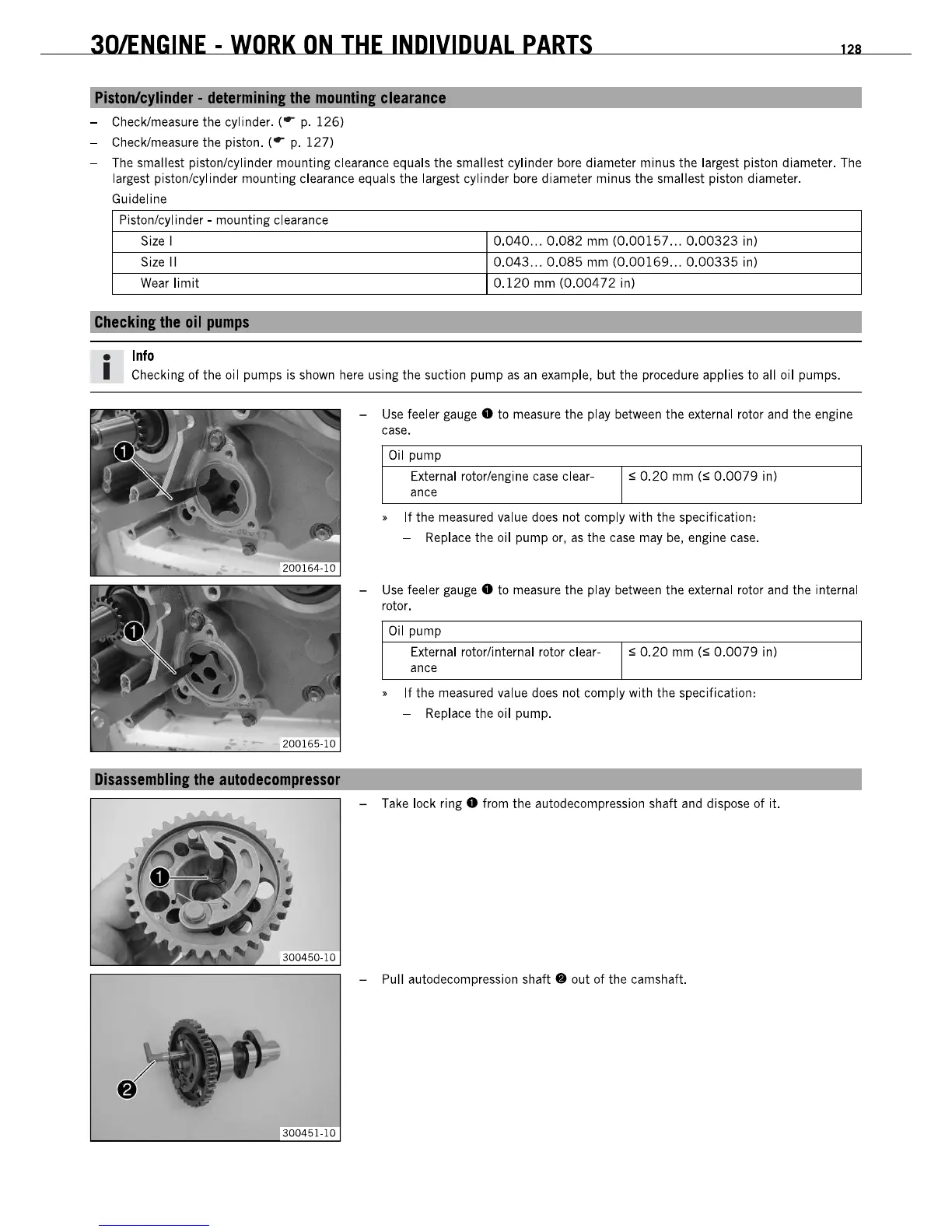

- Take lock

ring.

from the autodecompression shaft and dispose of it.

- Pull autodecompression

shaft.

out of the camshaft.

301ENGINE

-

WORK

ON

THE

INDIVIDUAL

PARTS

128

Piston/cYlinder

-

deterrnininllhe

mounti!!l

clearance

- Check/measure the cylinder. (r

p.

126)

- Check/measure the piston. (r

p.

127)

- The smallest piston/cylinder mounting clearance equals the smallest cylinder bore diameter minus the largest piston diameter. The

largest piston/cylinder mounting clearance equals the largest cylinder bore diameter minus the smallest piston diameter.

Guideline

Piston/cylinder - mounting clearance

Size I

0.040

...

0.082

mm

(0.00157

...

0.00323

in)

Size

II

0.043

...

0.085

mm

(0.00169

...

0.00335

in)

Wear

limit

0.120

mm

(0.00472

in)

Chackinl

tha

oil

pum~

•

Info

I Checking of the oil pumps is shown here using the suction pump

as

an

example, but the procedure applies

to

all oil pumps.

Disassamblinllha

autodacomprassor

30045\-10

-

Use

feeler

gauge.

to measure the play between the external rotor and the engine

case.

Oil pump

External rotor/engine case clear-

ance

I S

0.20

mm

(S

0.0079

in)

•

If

the measured value does not comply with the specification:

- Replace the oil pump

or,

as

the case may

be,

engine

case.

-

Use

feeler

gauge.

to measure the play between the external rotor and the internal

rotor.

Oil pump

External rotor/internal rotor clear-

I S

0.20

mm

(S

0.0079

in)

ance

•

If

the measured value does not comply with the specification:

- Replace the oil pump.

- Take lock

ring.

from the autodecompression shaft and dispose of it.

- Pull autodecompression

shaft.

out of the camshaft.

Loading...

Loading...