301ENGINE

-

WORK

ON

THE

INDIVIDUAL

PARTS

119

Guideline

Oil jet, piston cooling M5 2 Nm

Loctile-

243""

(1.5

Ibf

ft)

-

Mou

nt and tighten

oi

I jet

•.

Guideline

1 Oil jet, conrod lubrication

1 M6x0.75

14

Nm

(3 Ibf

ft)

•

•

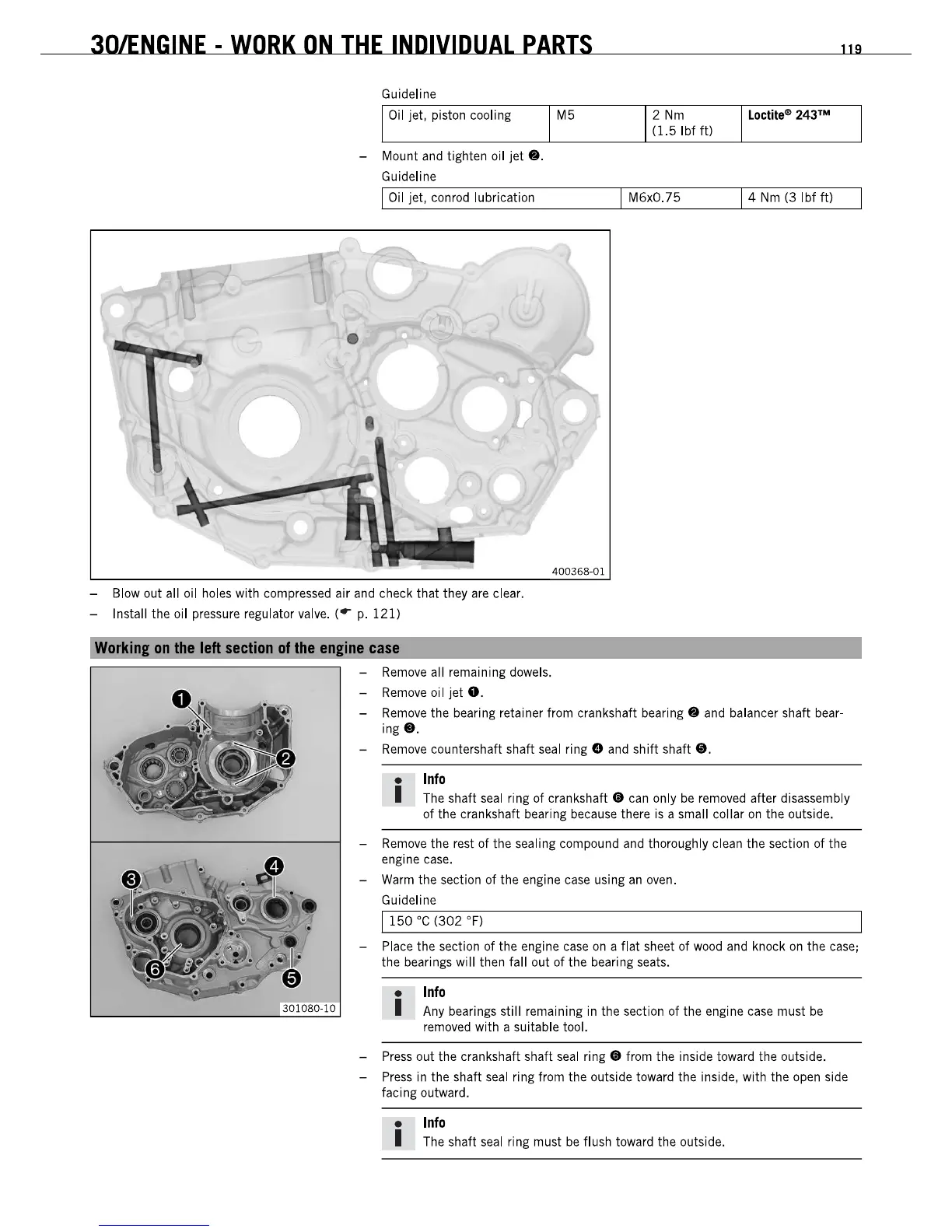

400368-01

-

Blowout

all oil holes with compressed air and check that they are clear.

- Install the oil pressure regulator valve. (

..

p.

121)

Workinl

on

ilia

laft

saction

of

tha

anlina

casa

-

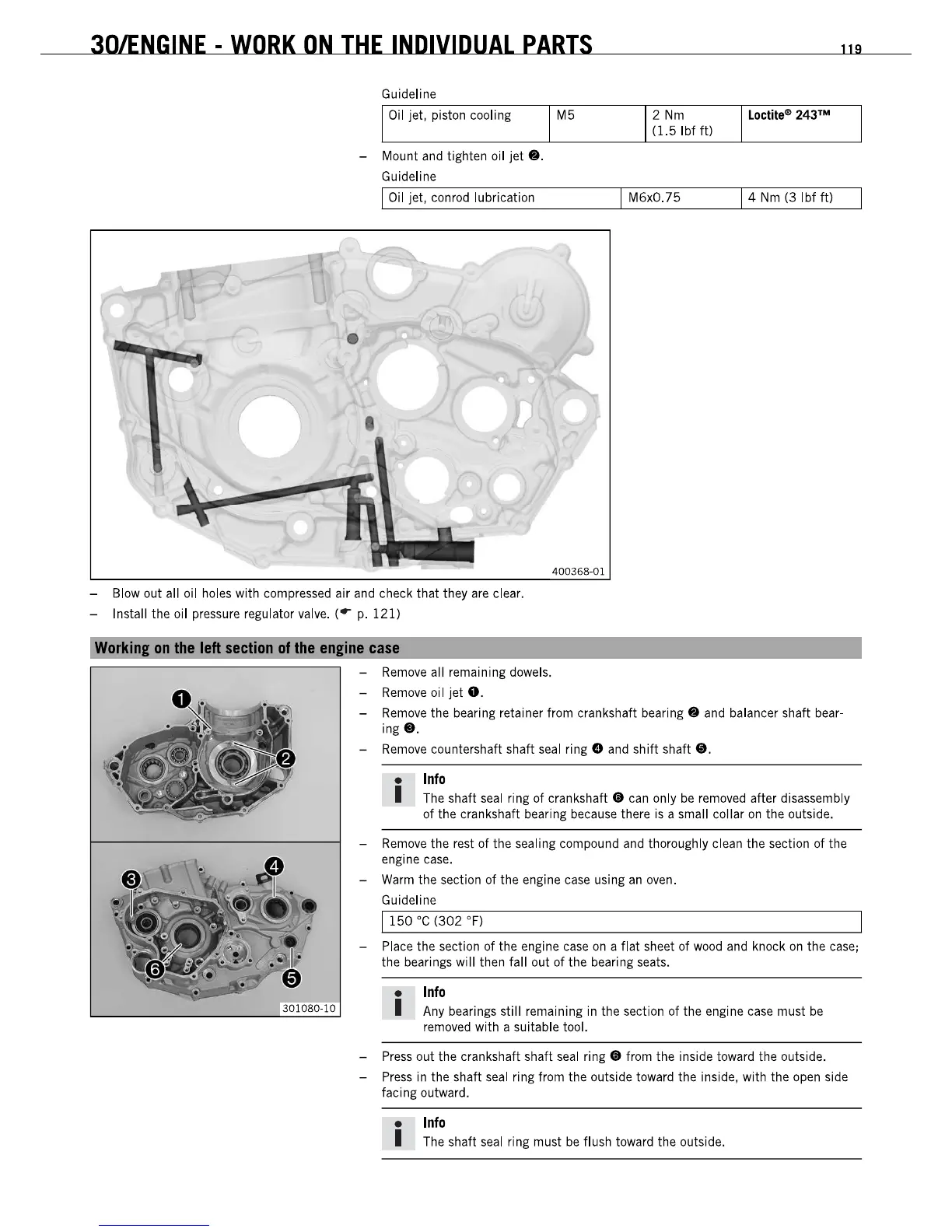

Remove

all remaining dowels.

-

Remove

oi

I jet

•.

-

Remove

the bearing retainer from crankshaft

bearing.

and balancer shaft bear-

ing

•.

-

Remove

countershaft shaft seal

ring.

and

shift

shaft

•.

_

Info

I The shaft

seal

ring of

crankshaft.

can only

be

removed after disassembly

of the crankshaft bearing because there

is

a small collar

on

the outside.

-

Remove

the rest of the sealing compound and thoroughly clean the section of the

engi

ne

case.

-

Warm

the section of the engine case using

an

oven.

Guideline

1150

°C

(302

OF)

- Place the section

of

the engine

case

on

a flat sheet

of

wood

and knock

on

the

case;

the bearings will then fall out of the bearing seats.

_

Info

I Any bearings still remaining in the section of the engine case must

be

removed with a suitable tool.

-

Press

out the crankshaft shaft seal

ring.

from the inside toward the outside.

-

Press

in the shaft seal ring from the outside toward the inside, with the open side

facing outward.

_

Info

I The shaft

seal

ring must

be

flush toward the outside.

301ENGINE

-

WORK

ON

THE

INDIVIDUAL

PARTS

119

Guideline

Oil jet, piston cooling M5 2 Nm

Loctile-

243""

(1.5

Ibf

ft)

-

Mou

nt and tighten

oi

I jet

•.

Guideline

1 Oil jet, conrod lubrication

1 M6x0.75

14

Nm

(3 Ibf

ft)

•

•

400368-01

-

Blowout

all oil holes with compressed air and check that they are clear.

- Install the oil pressure regulator valve. (

..

p.

121)

Workinl

on

ilia

laft

saction

of

tha

anlina

casa

-

Remove

all remaining dowels.

-

Remove

oi

I jet

•.

-

Remove

the bearing retainer from crankshaft

bearing.

and balancer shaft bear-

ing

•.

-

Remove

countershaft shaft seal

ring.

and

shift

shaft

•.

_

Info

I The shaft

seal

ring of

crankshaft.

can only

be

removed after disassembly

of the crankshaft bearing because there

is

a small collar

on

the outside.

-

Remove

the rest of the sealing compound and thoroughly clean the section of the

engi

ne

case.

-

Warm

the section of the engine case using

an

oven.

Guideline

1150

°C

(302

OF)

- Place the section

of

the engine

case

on

a flat sheet

of

wood

and knock

on

the

case;

the bearings will then fall out of the bearing seats.

_

Info

I Any bearings still remaining in the section of the engine case must

be

removed with a suitable tool.

-

Press

out the crankshaft shaft seal

ring.

from the inside toward the outside.

-

Press

in the shaft seal ring from the outside toward the inside, with the open side

facing outward.

_

Info

I The shaft

seal

ring must

be

flush toward the outside.

Loading...

Loading...