30JENGINE

-

WORK

ON

THE

INDIVIDUAL

PARTS

136

Chlckl!lllhift

mlchanlsm

~

/.

.

-r:!ZJ~

""@

,

.'.

@~~O

II/@~

~

e.

,%;{'O

....

8

--0

~

(I

'.

'.~\

°rtiftt

-·

~

ij

I

e-

CD-,

.

O

8-

~

~

~

e

~

--

e

Cit

200174-01

- Check needle

bearing.

and collar

sleeve.

for damage

and

wear.

~

If

there

is

damage

or

wear:

-

Change

the needle bearing and collar sleeve.

- Check the intermediate clutch

discs.

for damage and

wear.

» If

the

intermediate

discs

are

not

flat

or

have

punctiform

outbreaks:

-

Change

all intermediate discs.

-

Check

clutch

facing

discs.

for

discoloration

and

scoring.

»

If

there

is

discoloration

or

scoring:

-

Change

all clutch lining discs.

- Check the thickness

of

clutch facing discs

•.

Clutch facing disc - thickness

Outer

I

2.6

...

2.7

mm

(0.102

...

0.106

in)

Innermost

I

2.9

...

3.0

mm

(0.114

...

0.118

in)

•

If

the clutch lining disc does not meet specifications:

-

Change

all clutch lining discs.

- Check pretention ring and support

ring"

for damage and

wear.

» If

there

is

damage

or

wear:

-

Change

the pretension ring and support ring.

-

Check

the

inner

clutch

hub.

for

damage

and

wear.

»

If

there

is

damage

or

wear:

-

Change

the inner clutch hub.

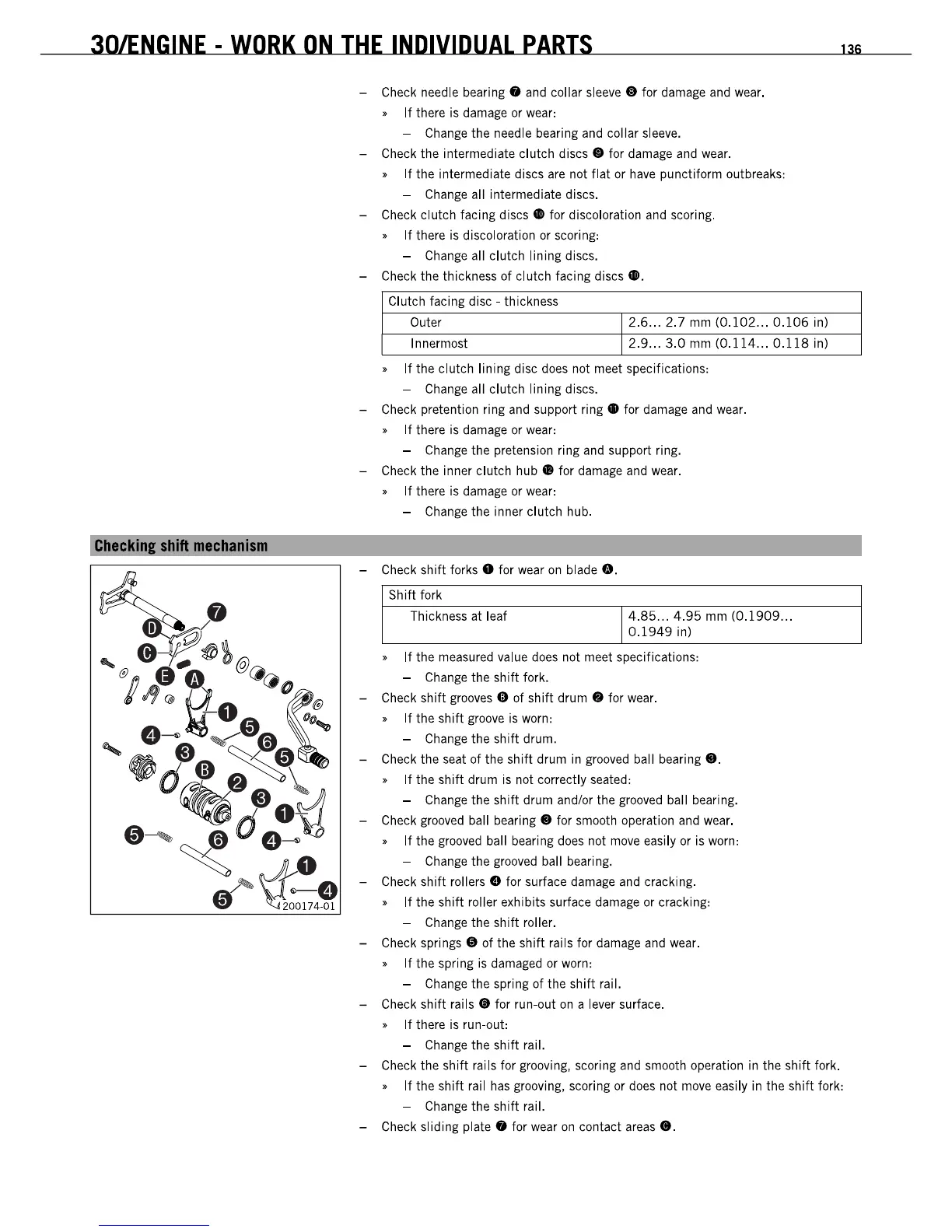

Check shift forks

0 for wear

on

blade

•.

Shift fork

Thickness at leaf

14.85

...

4.95

mm

(0.1909

...

0.1949

in)

•

If

the

measured

value

does

not

meet

specifications:

-

Change

the shift fork.

-

Check shift

grooves.

of shift

drum.

for wear.

•

If

the

shift

groove

is

worn:

-

Change

the shift drum.

-

Check the seat of the shift drum

in

grooved

ball bearing

•.

•

If

the shift drum is not correctly seated:

-

Change

the shift drum andlor the grooved ball bearing.

-

Check grooved ball

bearing.

for smooth operation and wear.

•

If

the

grooved

ball

bearing

does

not

move

easily

or

is

worn:

-

Change

the grooved ball bearing.

-

Check shift rollers 0 for surface damage and cracking.

•

If

the shift roller exhibits surface damage or cracking:

-

Change

the shift roller.

- Check

springs.

of the

shift

rails for damage

and

wear.

•

If

the spring is damaged or worn:

-

Change

the spring

of

the shift rail.

- Check shift

rails.

for run-out

on

a lever surface.

» If

there

is

run-out:

-

Change

the shift rail.

-

Check

the

shift

rails

for

grooving,

scoring

and

smooth

operation

in

the

shift

fork.

•

If

the shift rail

has

grooving, scoring or

does

not

move

easily in the shift fork:

-

Change

the shift rail.

- Check sliding

plate.

for wear

on

contact

areas

•.

I

30JENGINE

-

WORK

ON

THE

INDIVIDUAL

PARTS

136

Chlckl!lllhift

mlchanlsm

~

/.

.

-r:!ZJ~

""@

,

.'.

@~~O

II/@~

~

e.

,%;{'O

....

8

--0

~

(I

'.

'.~\

°rtiftt

-·

~

ij

I

e-

CD-,

.

O

8-

~

~

~

e

~

--e

Cit

200174-01

- Check needle

bearing.

and collar

sleeve.

for damage

and

wear.

~

If

there

is

damage

or

wear:

-

Change

the needle bearing and collar sleeve.

- Check the intermediate clutch

discs.

for damage and

wear.

» If

the

intermediate

discs

are

not

flat

or

have

punctiform

outbreaks:

-

Change

all intermediate discs.

-

Check

clutch

facing

discs.

for

discoloration

and

scoring.

»

If

there

is

discoloration

or

scoring:

-

Change

all clutch lining discs.

- Check the thickness

of

clutch facing discs

•.

Clutch facing disc - thickness

Outer

I

2.6

...

2.7

mm

(0.102

...

0.106

in)

Innermost

I

2.9

...

3.0

mm

(0.114

...

0.118

in)

•

If

the clutch lining disc does not meet specifications:

-

Change

all clutch lining discs.

- Check pretention ring and support

ring"

for damage and

wear.

» If

there

is

damage

or

wear:

-

Change

the pretension ring and support ring.

-

Check

the

inner

clutch

hub.

for

damage

and

wear.

»

If

there

is

damage

or

wear:

-

Change

the inner clutch hub.

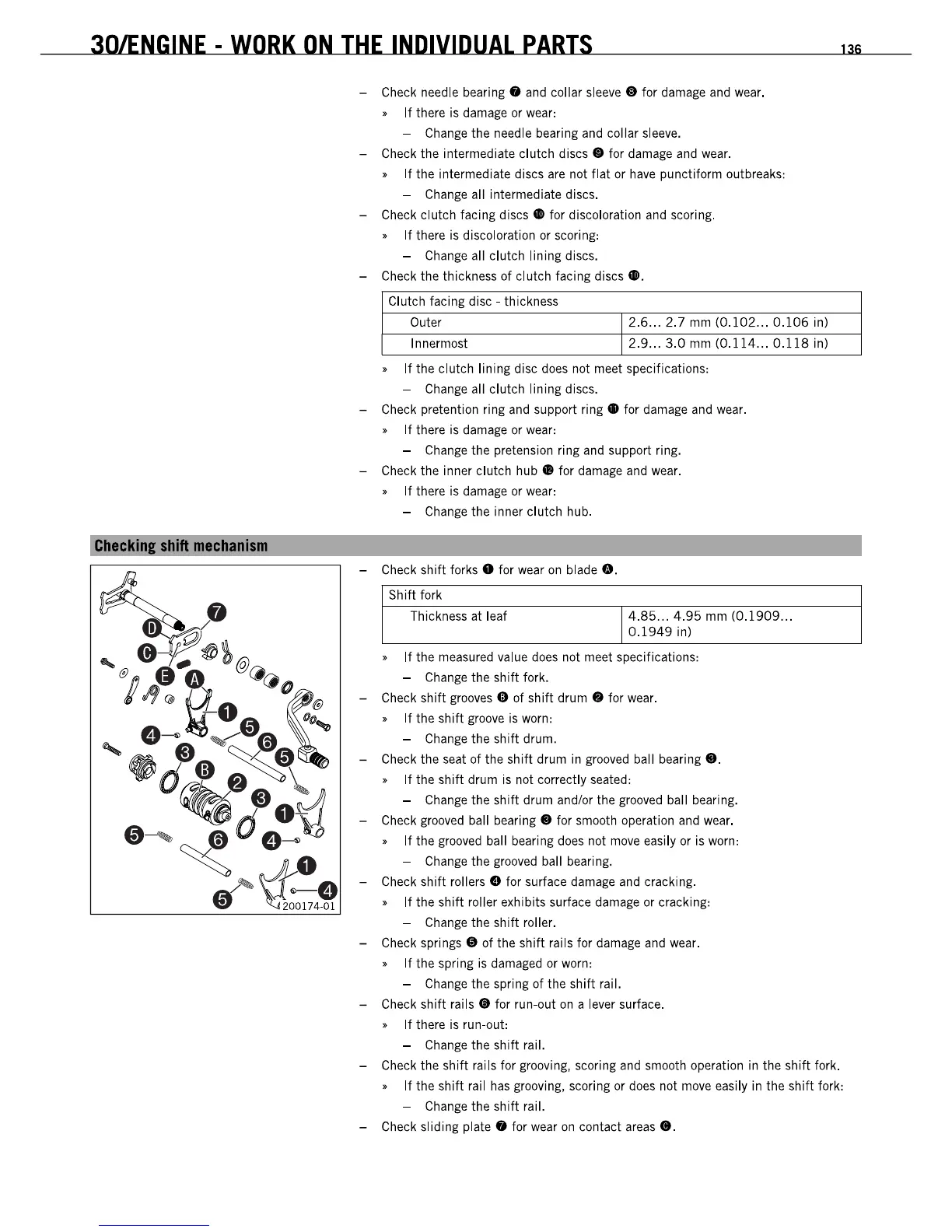

Check shift forks

0 for wear

on

blade

•.

Shift fork

Thickness at leaf

14.85

...

4.95

mm

(0.1909

...

0.1949

in)

•

If

the

measured

value

does

not

meet

specifications:

-

Change

the shift fork.

-

Check shift

grooves.

of shift

drum.

for wear.

•

If

the

shift

groove

is

worn:

-

Change

the shift drum.

-

Check the seat of the shift drum

in

grooved

ball bearing

•.

•

If

the shift drum is not correctly seated:

-

Change

the shift drum andlor the grooved ball bearing.

-

Check grooved ball

bearing.

for smooth operation and wear.

•

If

the

grooved

ball

bearing

does

not

move

easily

or

is

worn:

-

Change

the grooved ball bearing.

-

Check shift rollers 0 for surface damage and cracking.

•

If

the shift roller exhibits surface damage or cracking:

-

Change

the shift roller.

- Check

springs.

of the

shift

rails for damage

and

wear.

•

If

the spring is damaged or worn:

-

Change

the spring

of

the shift rail.

- Check shift

rails.

for run-out

on

a lever surface.

» If

there

is

run-out:

-

Change

the shift rail.

-

Check

the

shift

rails

for

grooving,

scoring

and

smooth

operation

in

the

shift

fork.

•

If

the shift rail

has

grooving, scoring or

does

not

move

easily in the shift fork:

-

Change

the shift rail.

- Check sliding

plate.

for wear

on

contact

areas

•.

I

Loading...

Loading...