Ol/FORK,

TRIPLE

CLAMP

23

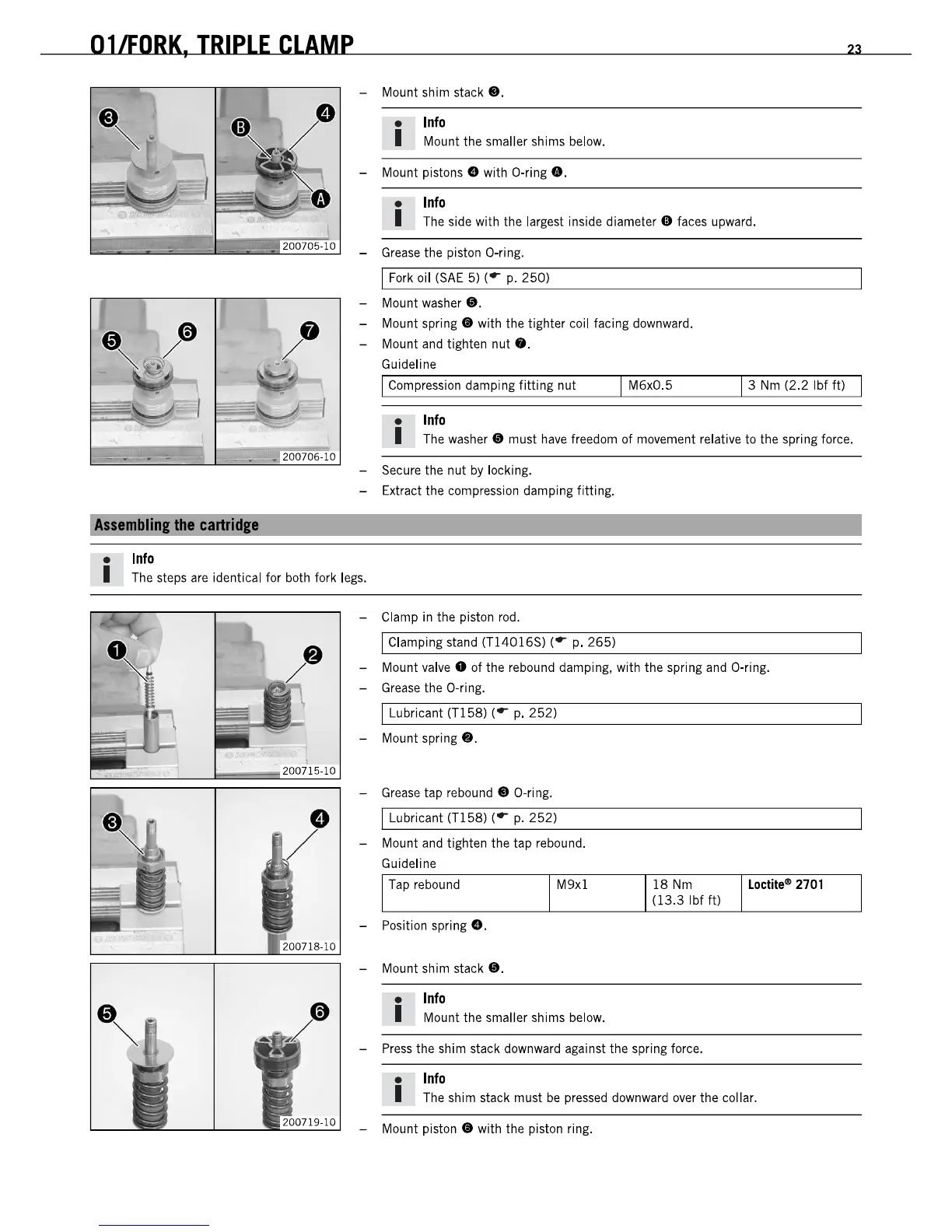

- Mount shim

stack

•.

•

Info

I Mount the smaller shims below.

- Mount

pistons.

with a-ring

•.

•

Info

I The side with the largest inside diameter

II

faces upward.

200705-10

Grease

the piston a-ring.

1

Fork

oil

(SAE

5) (

..

p.

250)

-

Mou

nt washer

•.

- Mount

spring.

with the tighter coil facing downward.

- Mount and tighten nut

•.

Guideline

1 Compression damping

fitting

nut

1 M6xO.5

13

Nm

(2.2 Ibf

It)

•

Info

I The

washer.

must

have

freedom of movement relative to the spring force.

_ 200706-10

- Secure the nut

by

locking.

- Extract the compression damping fitting.

Asslmbllnllllli

cartrldp-

•

Info

I The steps are identical for both fork

legs.

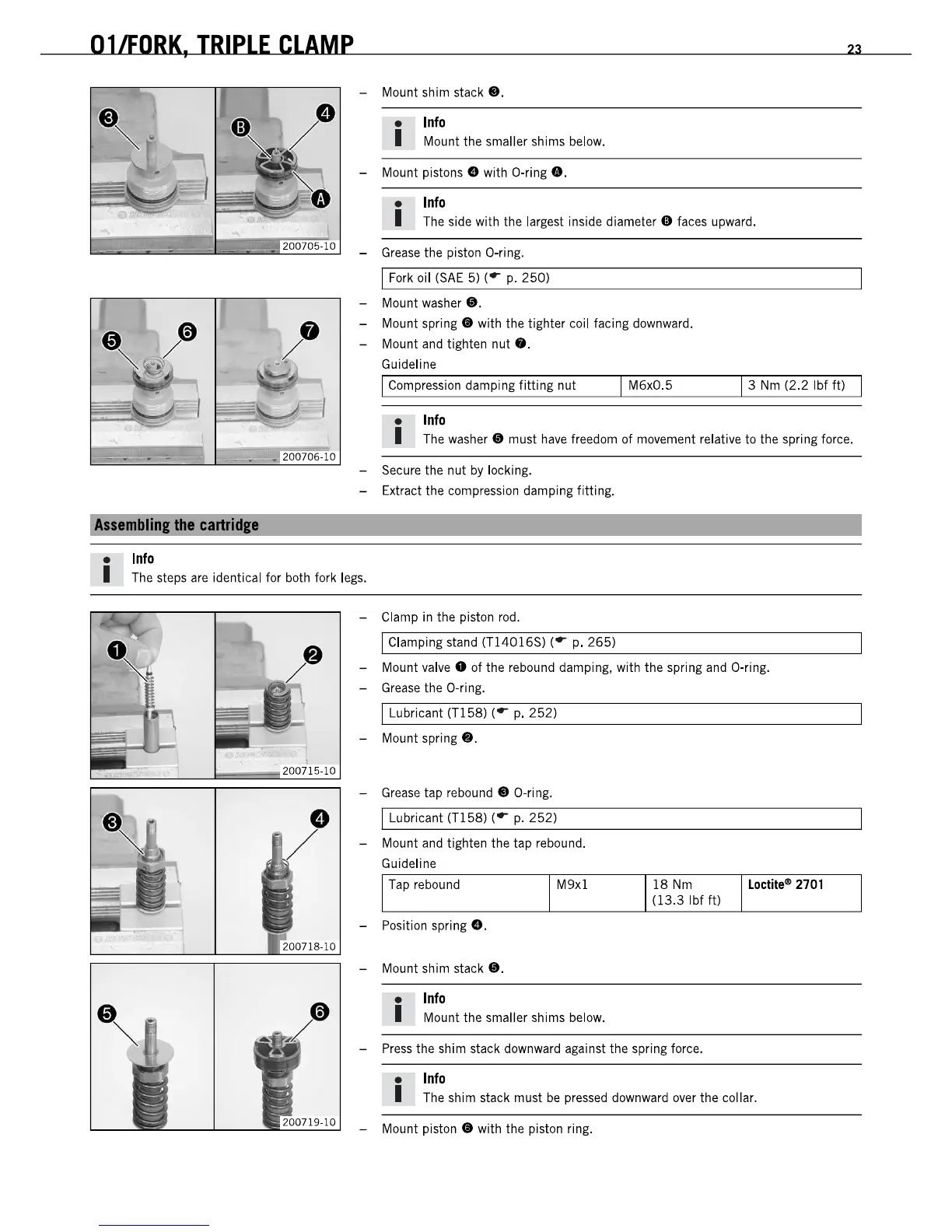

- Clamp

in

the piston rod.

1 Clamping stand

(Tl4016S)

(

..

p.

265)

- Mount

valve.

of the rebound damping, with the spring

and

a-ring.

-

Grease

the a-ring.

1 Lubricant

(Tl58)

(

..

p.

252)

-

Mou

nt spri

ng

•.

-

Grease

tap

rebound.

a-ring.

1 Lubricant

(Tl58)

(

..

p.

252)

- Mount and tighten the tap rebound.

Guideline

Tap rebound

M9xl

- Position spri

ng

•.

- Mount shim

stack

•.

•

Info

I Mount the smaller shims below.

18

Nm

(13.3 Ibf

It)

-

Press

the shim stack downward against the spring force.

•

Info

Lactile"'

2701

I The shim stack must

be

pressed

downward

over

the collar.

- Mount

piston.

with the piston ring.

Ol/FORK,

TRIPLE

CLAMP

23

- Mount shim

stack

•.

•

Info

I Mount the smaller shims below.

- Mount

pistons.

with a-ring

•.

•

Info

I The side with the largest inside diameter

II

faces upward.

200705-10

Grease

the piston a-ring.

1

Fork

oil

(SAE

5) (

..

p.

250)

-

Mou

nt washer

•.

- Mount

spring.

with the tighter coil facing downward.

- Mount and tighten nut

•.

Guideline

1 Compression damping

fitting

nut

1 M6xO.5

13

Nm

(2.2 Ibf

It)

•

Info

I The

washer.

must

have

freedom of movement relative to the spring force.

_ 200706-10

- Secure the nut

by

locking.

- Extract the compression damping fitting.

Asslmbllnllllli

cartrldp-

•

Info

I The steps are identical for both fork

legs.

- Clamp

in

the piston rod.

1 Clamping stand

(Tl4016S)

(

..

p.

265)

- Mount

valve.

of the rebound damping, with the spring

and

a-ring.

-

Grease

the a-ring.

1 Lubricant

(Tl58)

(

..

p.

252)

-

Mou

nt spri

ng

•.

-

Grease

tap

rebound.

a-ring.

1 Lubricant

(Tl58)

(

..

p.

252)

- Mount and tighten the tap rebound.

Guideline

Tap rebound

M9xl

- Position spri

ng

•.

- Mount shim

stack

•.

•

Info

I Mount the smaller shims below.

18

Nm

(13.3 Ibf

It)

-

Press

the shim stack downward against the spring force.

•

Info

Lactile"'

2701

I The shim stack must

be

pressed

downward

over

the collar.

- Mount

piston.

with the piston ring.

Loading...

Loading...