Ol/FORK,

TRIPLE

CLAMP

24

.J"-''''

•

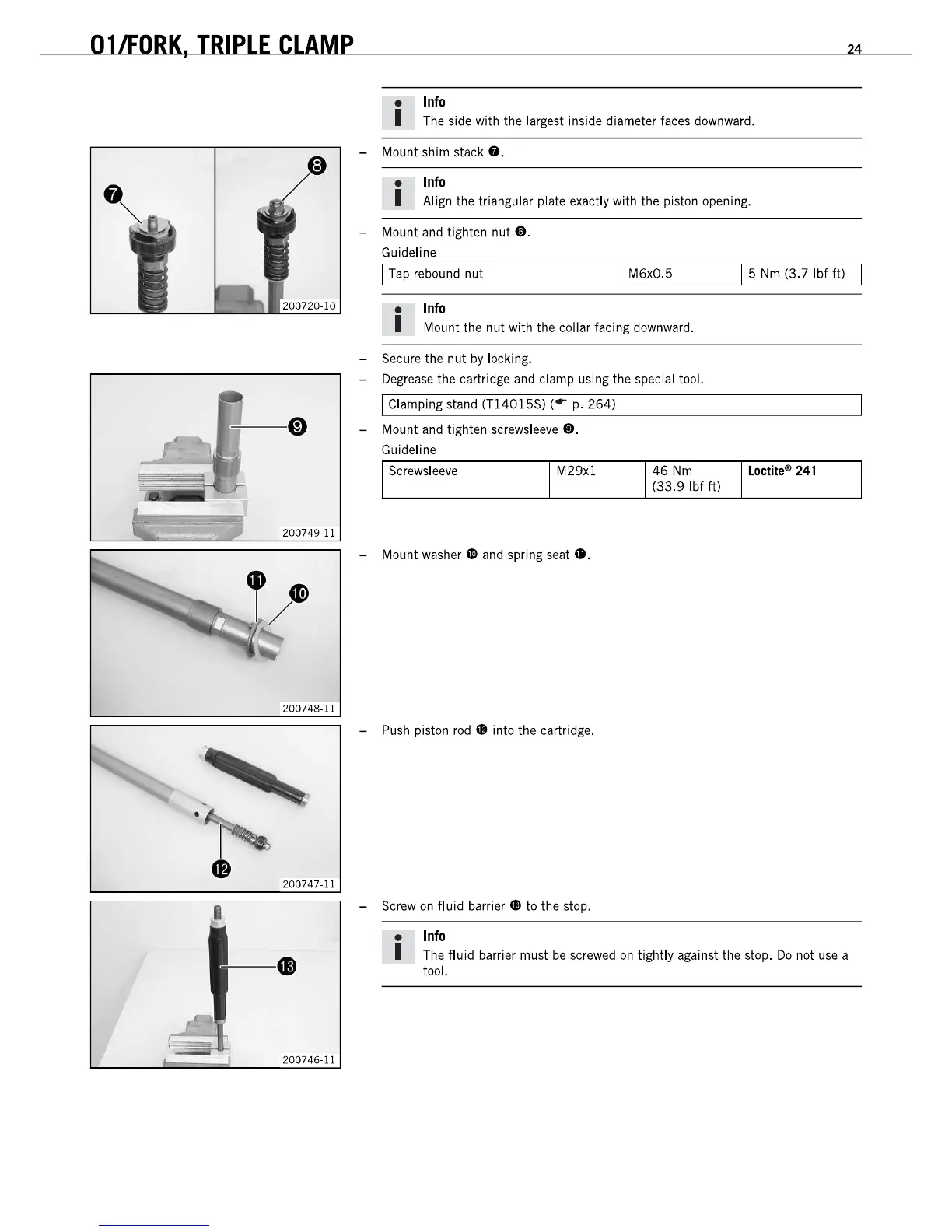

Info

I The side with the largest inside diameter faces downward.

- Mount shim

stack

•.

•

Info

I Align the triangular plate exactly with the piston opening.

- Mount and tighten nut

•.

Guideline

1 Tap rebound nut

1 M6xO.5

15

Nm

(3.7 Ibf

It)

•

Info

I Mount the nut with the collar facing downward.

- Secure the nut

by

locking.

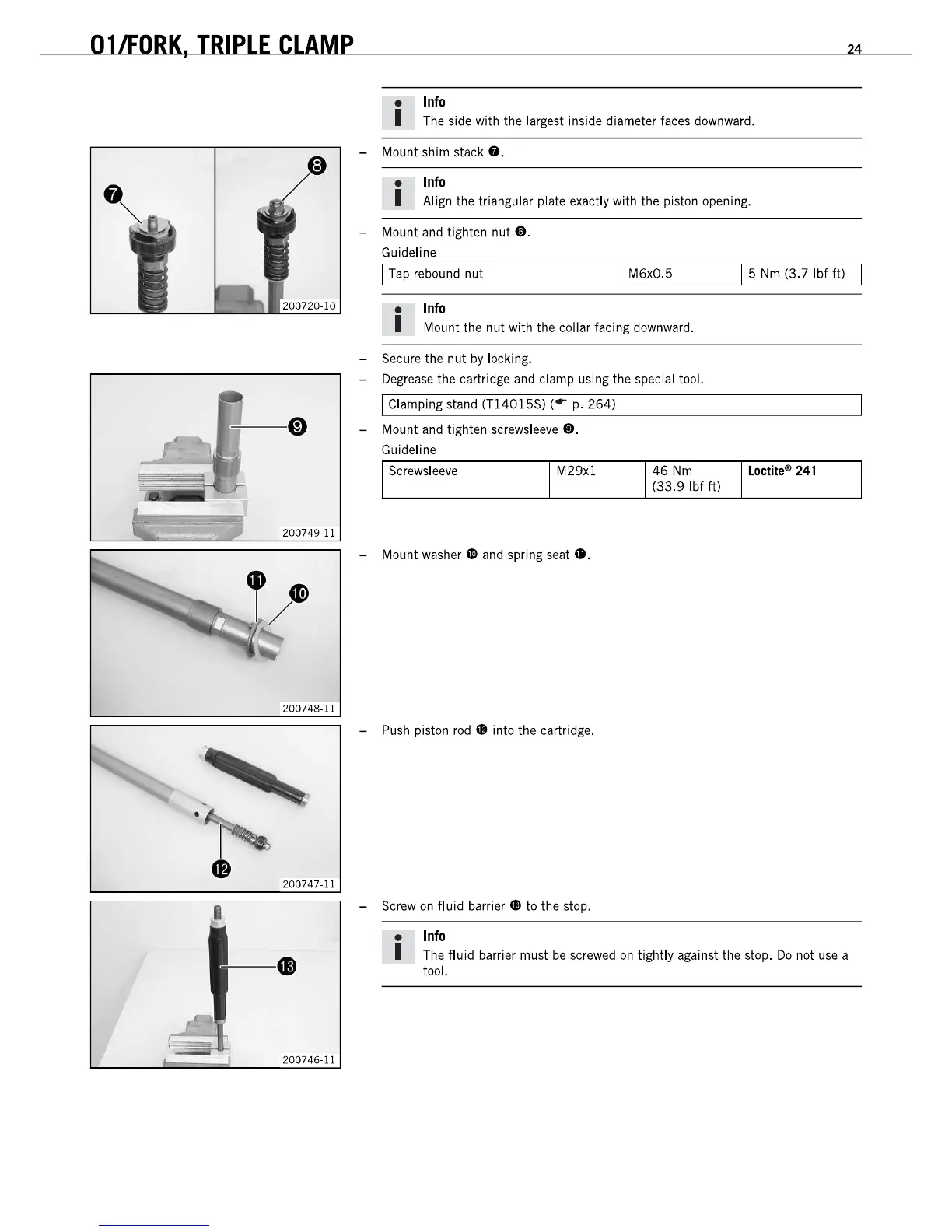

-

Degrease

the cartridge and clamp using the special tool.

1 Clamping stand (T14015S) (

..

p.

264)

l"

t--

--,0

- Mount and tighten screwsleeve

•.

20074!HI

200741HI

200747-11

I

200746-11

Guideline

Screwsleeve

M29xl

- Mount

washer.

and spring seat e.

-

Push

piston

rod

• into the cartridge.

- Screw

on

fluid

barrier.

to the stop.

•

Info

46

Nm

(33.9

Ibf

It)

Loctitee

241

I The fluid barrier must

be

screwed

on

tightly against the stop.

Do

not

use

a

tool.

Ol/FORK,

TRIPLE

CLAMP

24

.J"-''''

•

Info

I The side with the largest inside diameter faces downward.

- Mount shim

stack

•.

•

Info

I Align the triangular plate exactly with the piston opening.

- Mount and tighten nut

•.

Guideline

1 Tap rebound nut

1 M6xO.5

15

Nm

(3.7 Ibf

It)

•

Info

I Mount the nut with the collar facing downward.

- Secure the nut

by

locking.

-

Degrease

the cartridge and clamp using the special tool.

1 Clamping stand (T14015S) (

..

p.

264)

l"

t--

--,0

- Mount and tighten screwsleeve

•.

20074!HI

200741HI

200747-11

I

200746-11

Guideline

Screwsleeve

M29xl

- Mount

washer.

and spring seat e.

-

Push

piston

rod

• into the cartridge.

- Screw

on

fluid

barrier.

to the stop.

•

Info

46

Nm

(33.9

Ibf

It)

Loctitee

241

I The fluid barrier must

be

screwed

on

tightly against the stop.

Do

not

use

a

tool.

Loading...

Loading...