301ENGINE

-

WORK

ON

THE

INDIVIDUAL

PARTS

120

•

-

Warm

up the section

of

the engine

case

again.

Guideline

1150

°C

(302

OF)

- Insert the

new

cold bearings in the bearing seats of the heated section of the

engine case;

if

necessary,

use

a suitable press

drift

to push them all the

way

in and

make them flush.

•

Info

I

When

pressing in, ensure that the section of the engine case lies

flat

in

order prevent damage.

Only press in the bearings

by

way

of the outer ring,

as

otherwise the bear-

ings will

be

damaged when they are

pressed

in.

- After the section of the engine case has cooled down, check

to

ensure that the

bearings

are

firmly seated.

•

Info

I

If

the bearings are not firmly seated once cooled down,

it

can

be

assumed

that the bearing races will turn in the engine case at higher temperatures.

In

this case, the engine case needs

to

be

replaced.

- Position all bearing retainers. Mount and tighten the screws.

Guideline

Locking screw for bearing M5

6Nm

Loctile-

243""

(4.4

Ibf

ft)

-

Press

countershaft shaft seal

ring.

and shift

shaft.

in flush, with the open side

facing inward.

-

Mou

nt and tighten

oi

I jet

•.

Guideline

Oil jet, piston cooling M5

2

Nm

Loctilee

243""

(1.5

Ibf

ft)

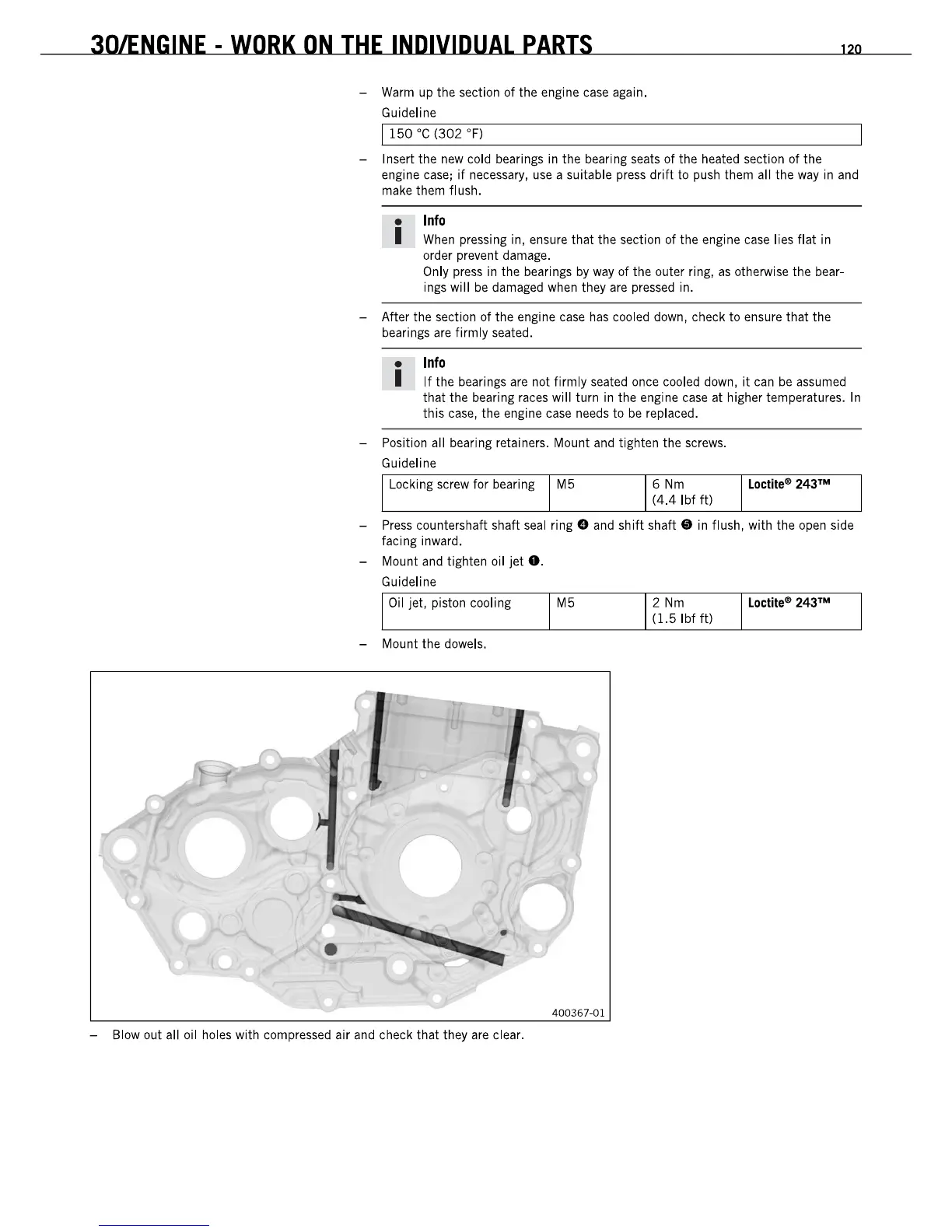

- Mount the dowels .

40036]'{1l

-

Blowout

all oil holes with compressed air and check that they are clear.

301ENGINE

-

WORK

ON

THE

INDIVIDUAL

PARTS

120

•

-

Warm

up the section

of

the engine

case

again.

Guideline

1150

°C

(302

OF)

- Insert the

new

cold bearings in the bearing seats of the heated section of the

engine case;

if

necessary,

use

a suitable press

drift

to push them all the

way

in and

make them flush.

•

Info

I

When

pressing in, ensure that the section of the engine case lies

flat

in

order prevent damage.

Only press in the bearings

by

way

of the outer ring,

as

otherwise the bear-

ings will

be

damaged when they are

pressed

in.

- After the section of the engine case has cooled down, check

to

ensure that the

bearings

are

firmly seated.

•

Info

I

If

the bearings are not firmly seated once cooled down,

it

can

be

assumed

that the bearing races will turn in the engine case at higher temperatures.

In

this case, the engine case needs

to

be

replaced.

- Position all bearing retainers. Mount and tighten the screws.

Guideline

Locking screw for bearing M5

6Nm

Loctile-

243""

(4.4

Ibf

ft)

-

Press

countershaft shaft seal

ring.

and shift

shaft.

in flush, with the open side

facing inward.

-

Mou

nt and tighten

oi

I jet

•.

Guideline

Oil jet, piston cooling M5

2

Nm

Loctilee

243""

(1.5

Ibf

ft)

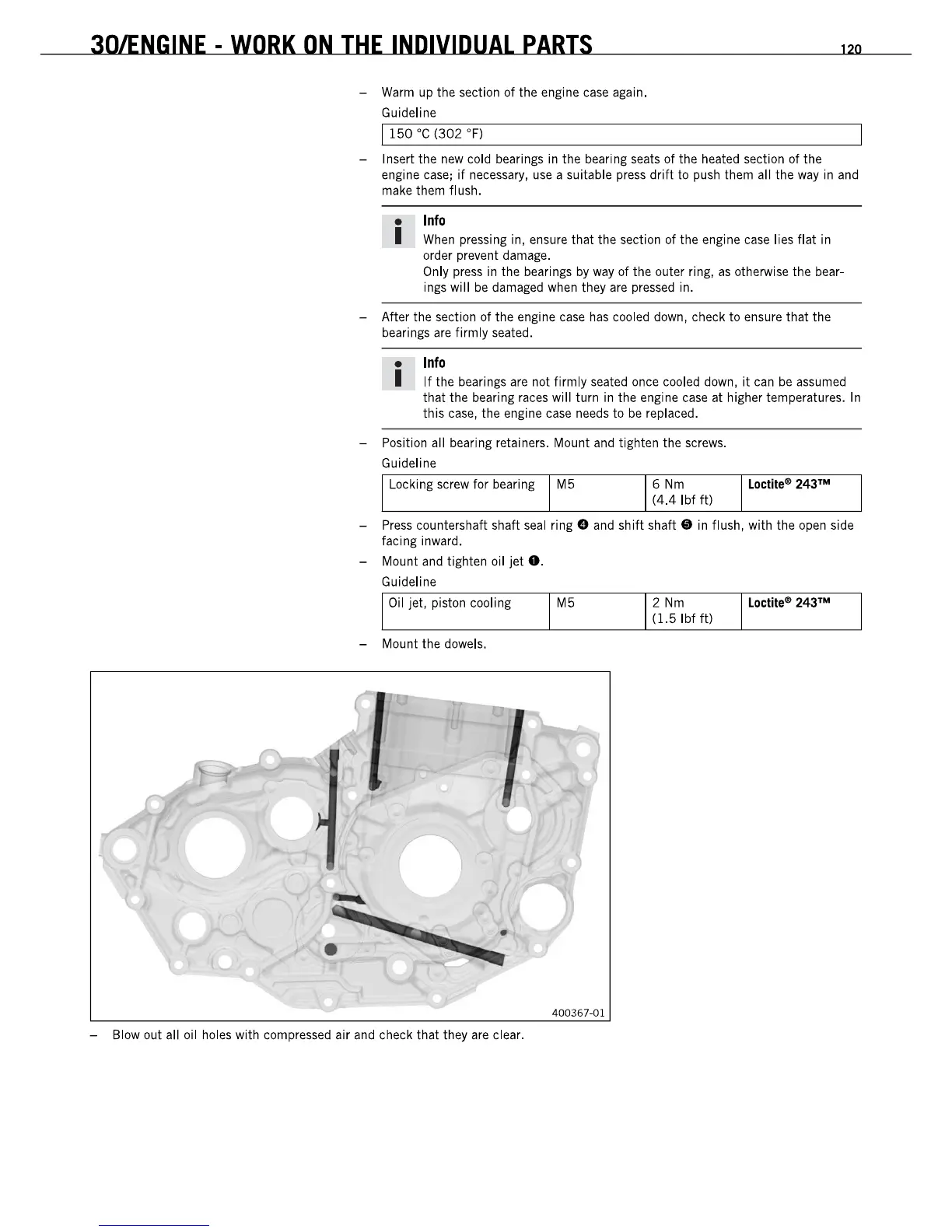

- Mount the dowels .

40036]'{1l

-

Blowout

all oil holes with compressed air and check that they are clear.

Loading...

Loading...