30/ENGINE - WORK ON INDIVIDUAL PARTS 125

400375-10

– Check the sealing area of the cylinder for distortion using a straight edge and the

special tool.

Feeler gauge (59029041100) ( p. 214)

Cylinder/cylinder head - sealing area

distortion

≤ 0.10 mm (≤ 0.0039 in)

» If the measured value does not equal the specified value:

– Change the cylinder head.

400373-10

– Check sealing seat of the valves.

Valve - sealing seat width

Intake 1.60 mm (0.063 in)

Valve - sealing seat width

Exhaust 2.00 mm (0.0787 in)

» If the measured value does not equal the specified value:

– Machine the valve seat.

– Blow compressed air through all oil holes and check that they are clear.

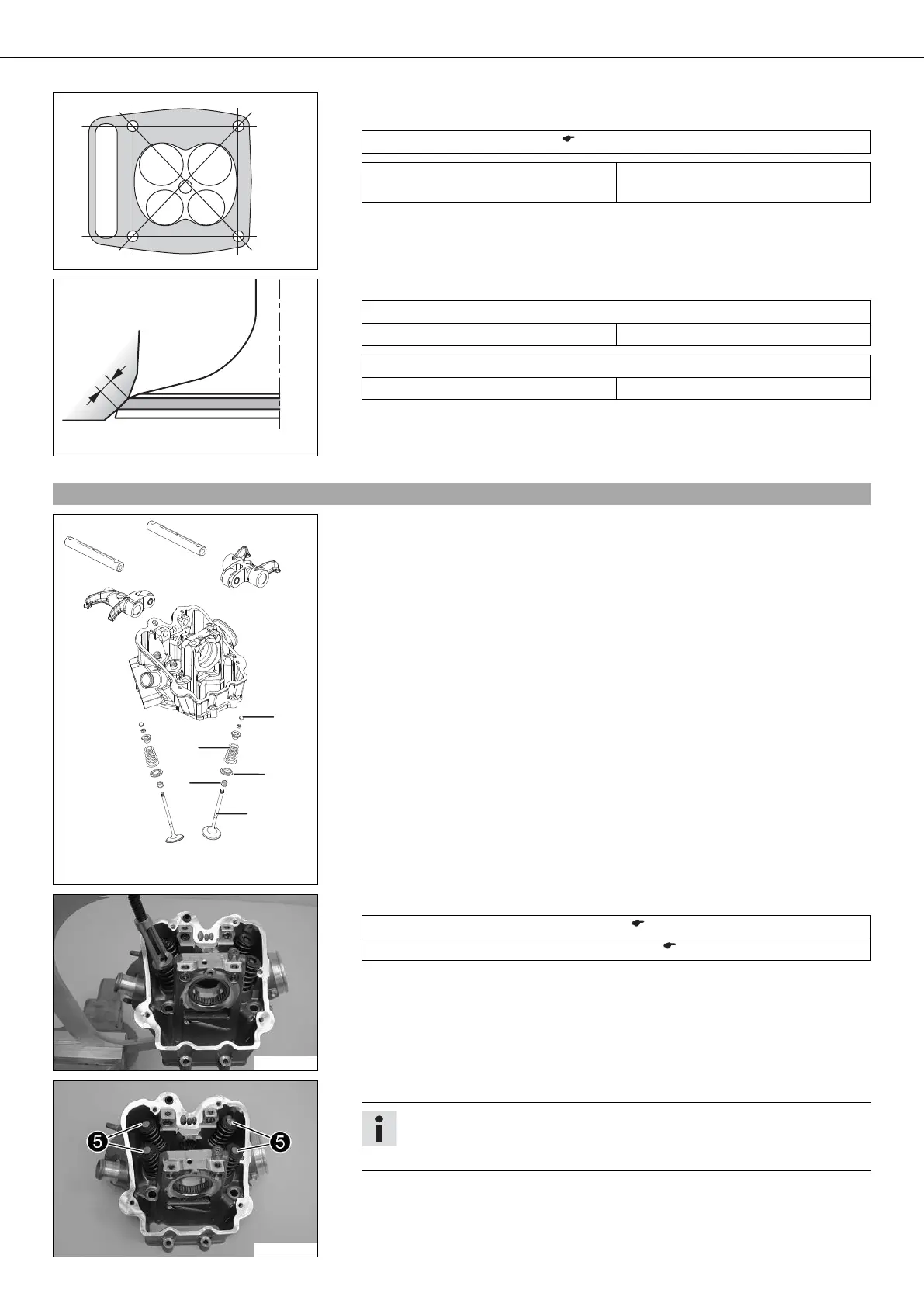

19.27Installing valves

300118-01

– Position the valve spring cap . Install new valve stem seals .

– Install the valves according to their normal built-in position.

– Install the valve springs and the spring retainers.

300116-11

– Pretension the valve springs using the special tool.

Valve spring compressor (59029019000) ( p. 213)

Valve spring mounting device (78029060000) ( p. 220)

300115-11

– Mount valve keys.

Info

When mounting the valve keys, check that they are seated correctly; prefer-

ably, fix the valve keys to the valve with a little grease.

– Place shims into the valve spring retainers according to the installation position.

Loading...

Loading...