30/ENGINE - WORK ON INDIVIDUAL PARTS 129

19.12Checking/measuring the cylinder

300102-10

– Check the O-ring of the chain adjuster for damage and wear.

» If there is damage or wear:

– Replace the O-ring.

– Check the cylinder bearing surface for damage.

» If the cylinder bearing surface is damaged:

– Change the cylinder and piston.

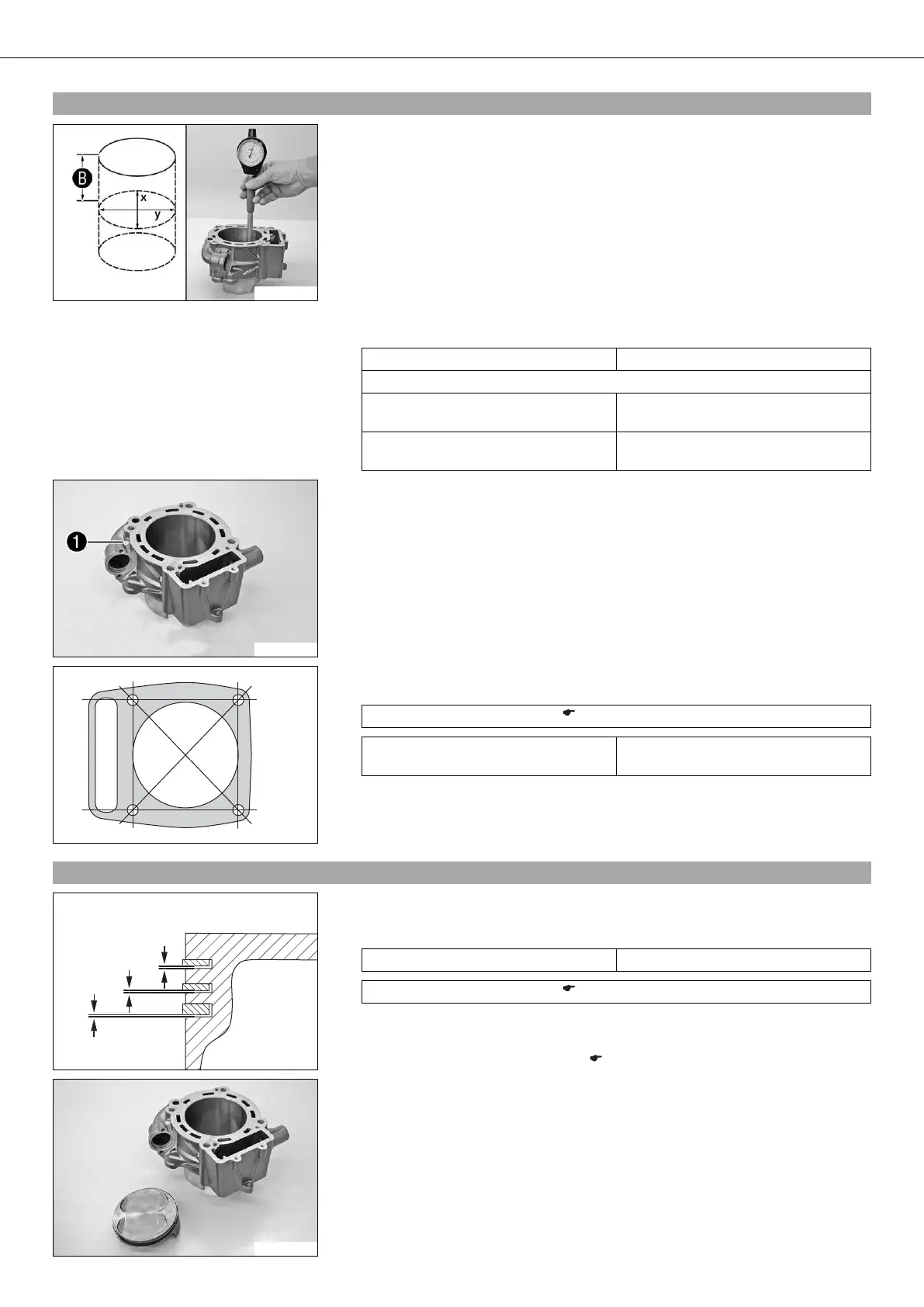

– Measure the cylinder diameter at several places in the and axes using a

micrometer to check for oval wear.

– To determine the size, measure the cylinder at a distance from the top edge of

the cylinder.

Guideline

Distance 55 mm (2.17 in)

Cylinder - bore diameter

Size I 102.000… 102.012 mm (4.01574…

4.01621 in)

Size II 102.013… 102.025 mm (4.01625…

4.01672 in)

300103-10

– The cylinder size is marked on the side of the cylinder.

400376-10

– Check the sealing area of the cylinder head for distortion using a straight edge and

the special tool.

Feeler gauge (59029041100) ( p. 248)

Cylinder/cylinder head - sealing area

distortion

≤ 0.10 mm (≤ 0.0039 in)

» If the measured value does not equal the specified value:

– Change the cylinder.

19.13Checking/measuring the piston

400484-10

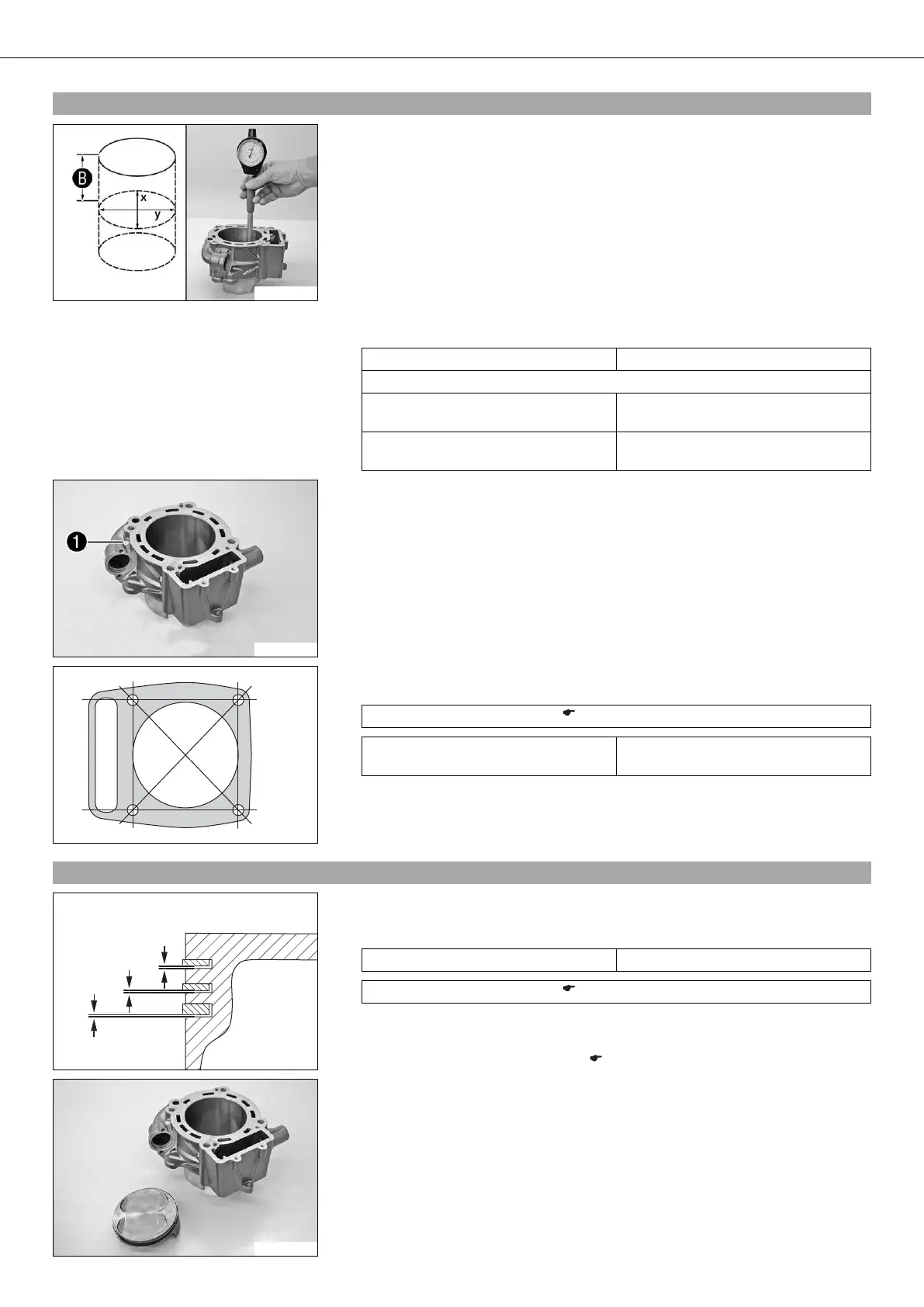

– Use the special tool to measure clearance of the piston rings in the piston ring

groove.

Guideline

Piston ring - groove clearance ≤ 0.08 mm (≤ 0.0031 in)

Feeler gauge (59029041100) ( p. 248)

» If clearance is larger than the specified value:

– Change the piston and piston rings.

– Check/measure the cylinder. ( p. 129)

300099-10

– Check the piston bearing surface for damage.

» If the piston bearing surface is damaged:

– Change the piston and, if necessary, the cylinder.

– Check that the piston rings can move easily in the piston ring grooves.

» If the piston ring is stiff:

Loading...

Loading...