30/ENGINE - WORK ON INDIVIDUAL PARTS 148

– Replace the starter idler gear and/or needle bushing.

– Check the teeth and seating of the torque limiter for damage and wear.

» If there is damage or wear:

– Replace the torque limiter and/or needle bushing.

– Check freewheel gear and bearing when removed for damage and wear.

» If there is damage or wear:

– Replace the freewheel gear and/or the bearing.

– Check the freewheel when removed for damage and wear.

» If there is damage or wear:

– Replace the freewheel.

– Check the toothing of the starter motor for damage and wear.

» If there is damage or wear:

– Replace the starter motor.

– Clamp the minus (negative) cable of a 12 Volt power supply to the starter motor housing. Briefly connect the plus (positive) cable

of the power supply to the starter motor connection.

» If the starter motor does not turn when you close the power circuit:

– Replace the starter motor.

– Replace the O-ring of the starter motor.

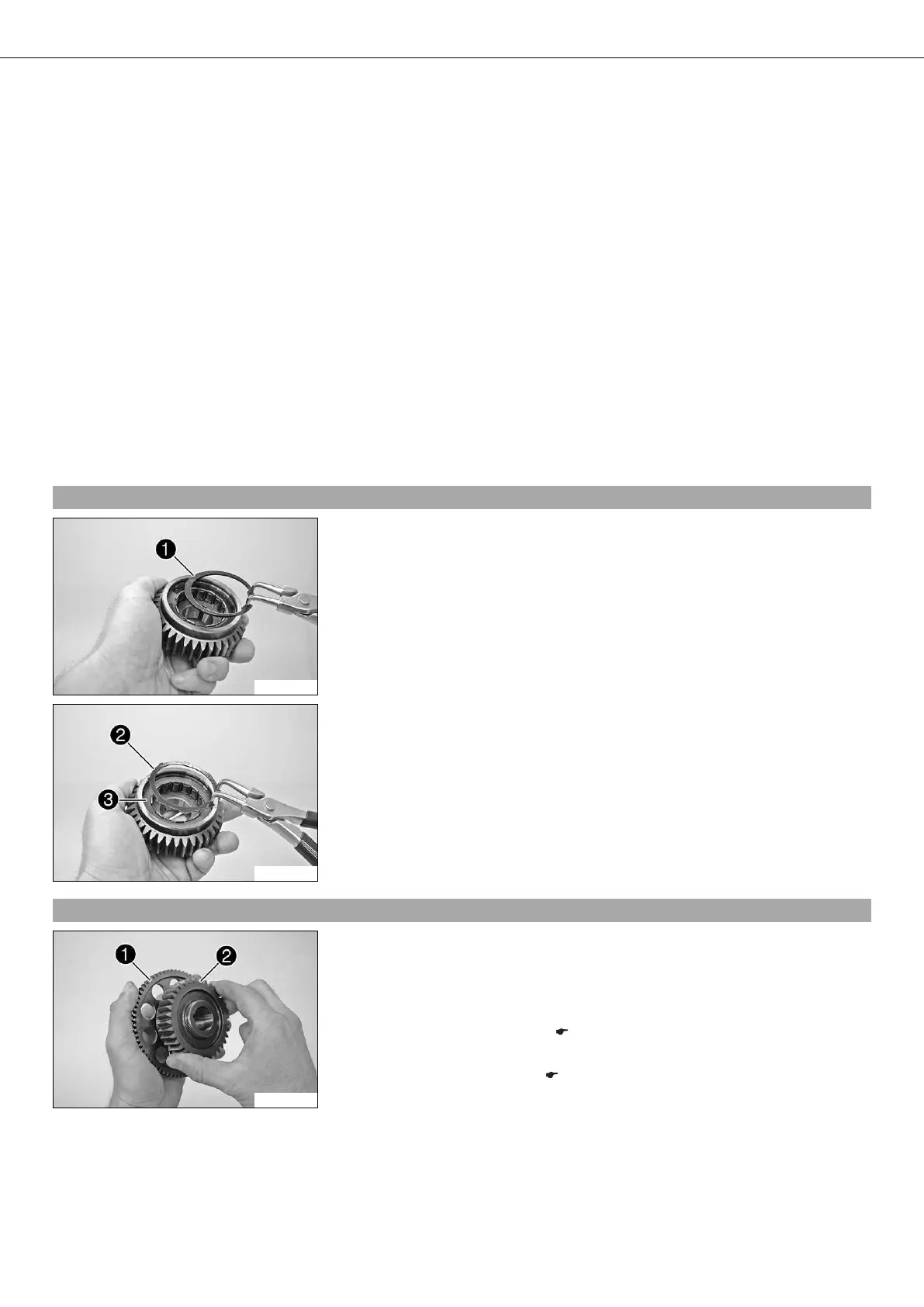

19.40Removing freewheel

300127-10

– Extract the lock ring from the groove using suitable pliers.

300128-10

– Compress the expansion ring and remove it, using suitable pliers.

– Take the freewheel out of the primary gear.

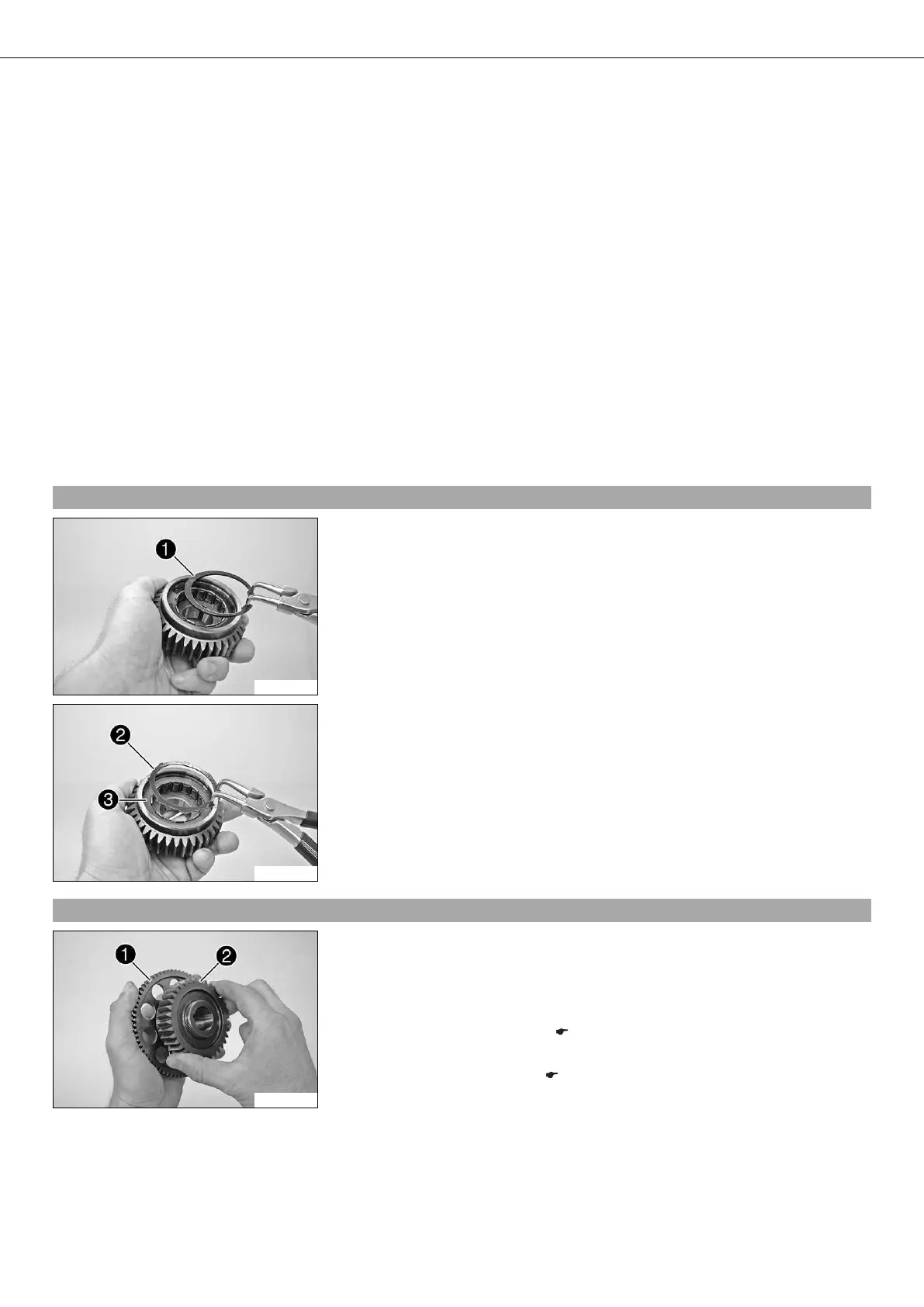

19.41Checking freewheel

300131-10

– Insert the freewheel gear in the primary gear , turning the primary gear clock-

wise; do not twist!

– Check the locking action of the freewheel gear .

» If the primary gear does not turn clockwise or if it does not lock counterclock-

wise:

– Remove the freewheel. ( p. 148)

– Turn the freewheel 180°.

– Install the freewheel. ( p. 149)

Loading...

Loading...