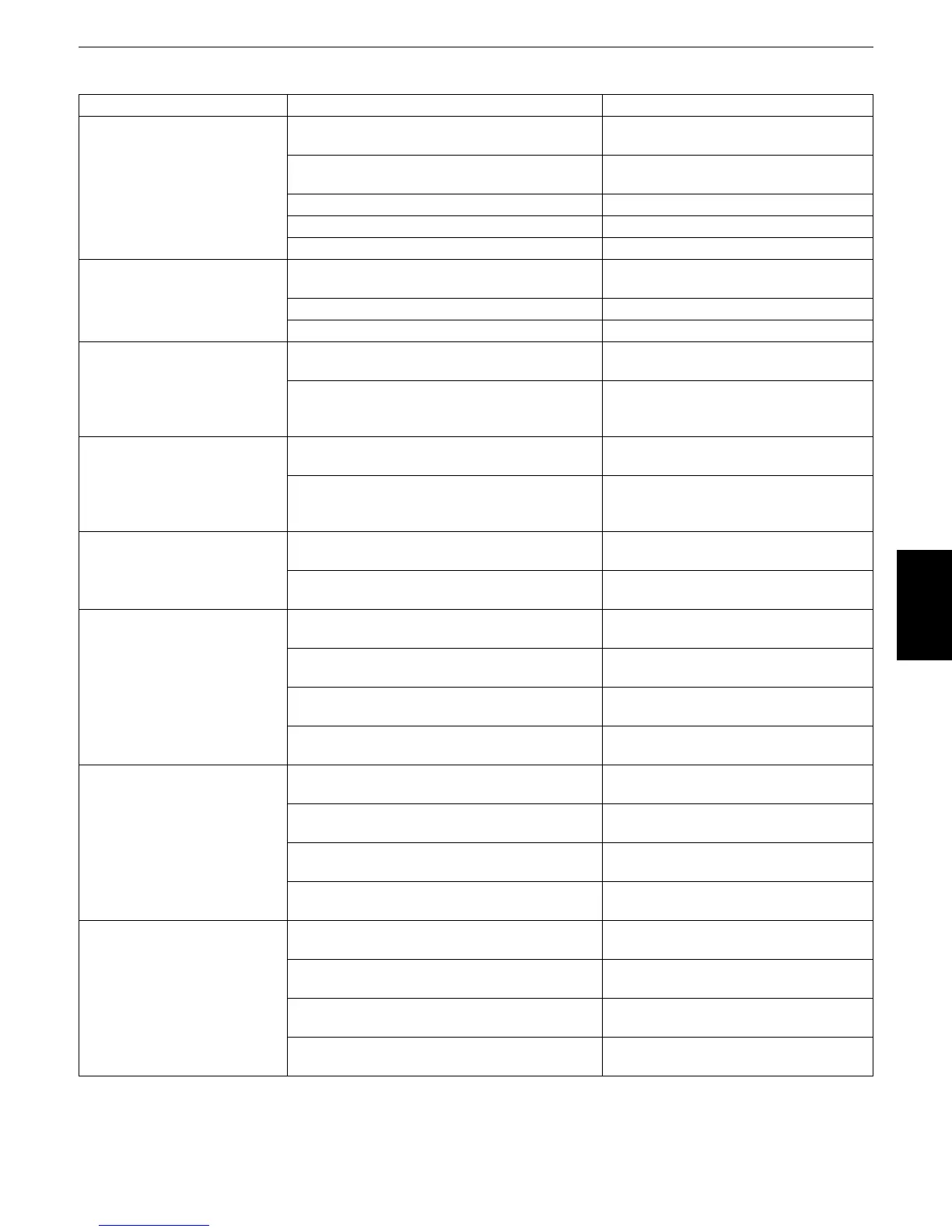

U20-3, U25-3 WSM Hydraulic system (Service section)

IV-S-4

b. Hydraulics

Problem Cause Correction

The entire hydraulic system fails

or responds too slow or too

weak.

(1) Hydraulic oil too short in the tank or oil

degraded.

Add or change the hydraulic oil.

(2) Suction line (suction filter) clogged.

Check the suction line and replace the

suction filter as required.

(3) Pump coupling defective. Repair or replace the pump coupling.

(4) Pump drive shaft broken. Replace the shaft.

(5) Pump internal parts seized or damaged. Repair or replace the pump.

The boom, arm, bucket and

swivel mechanism fail or

respond too slow or too weak.

(1) Hydraulic pilot filter or hydraulic pilot line filter

clogged.

Clean or replace the pilot filter.

(2) Selector valve defective. Overhaul or replace the selector valve.

(3) Pilot pump internal parts seized or damaged. Replace the pilot pump.

The boom, bucket and right-

travel mechanism fail or respond

too slow or too weak.

(1) Main relief valve (P1) not at specified

pressure.

Check the main relief valve (P1) and

readjust as required.

(2) P1 or P2 line pump internal parts seized or

damaged if the arm, service port and left-travel

mechanism fail too.

Overhaul or replace the pump.

The arm, service port and left-

travel mechanism fail or respond

too slow or too weak.

(1) Main relief valve (P2) not at specified

pressure.

Check the main relief valve (P2) and

readjust as required.

(2) P1 or P2 line pump internal parts seized or

damaged if the boom, bucket and right-travel

mechanism fail too.

Overhaul or replace the pump.

The swing, dozer and swivel

mechanism fail or respond too

slow or too weak.

(1) Main relief valve (P3) not at specified

pressure.

Check the main relief valve (P3) and

readjust as required.

(2) P3 line pump internal parts seized or

damaged.

Overhaul or replace the pump.

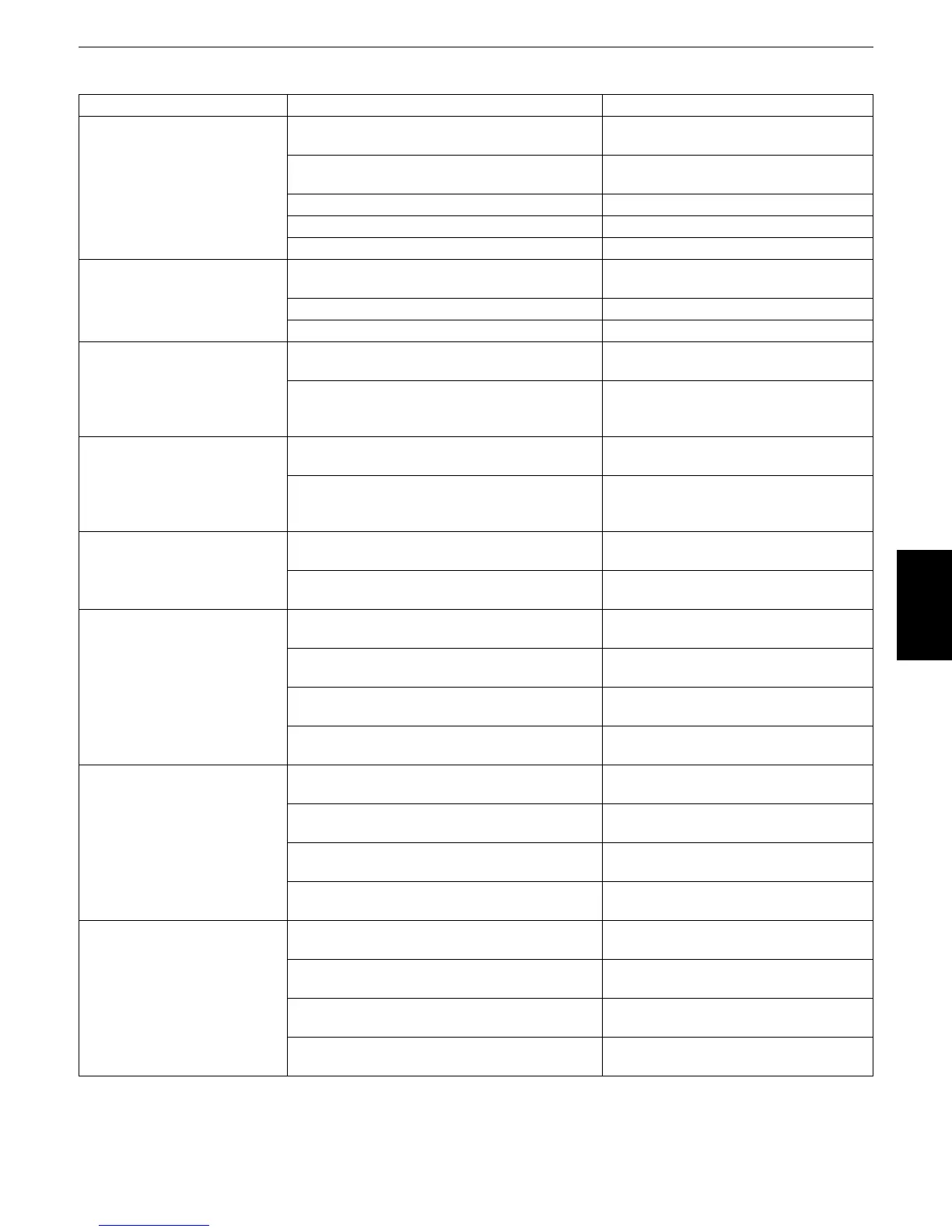

The boom alone fails or

responds too slow or too weak.

(1) Boom overload relief valve not at specified

pressure.

Check the overload relief valve and repair

as required.

(2) Control valve or boom section spool

malfunctioning.

Check the spool and repair as required.

(3) Pilot valve defective.

Measure the secondary pressure and

check the pilot valve.

(4) Boom cylinder rod packing broken.

Overhaul the cylinder and replace the

sealing.

The arm alone fails or responds

too slow or too weak.

(1) Arm overload relief valve not at specified

pressure.

Check the overload relief valve and repair

as required.

(2) Control valve or arm section spool

malfunctioning.

Check the spool and repair as required.

(3) Pilot valve defective.

Measure the secondary pressure and

check the pilot valve.

(4) Arm cylinder rod packing broken.

Overhaul the cylinder and replace the

sealing.

The bucket alone fails or

responds too slow or too weak.

(1) Bucket overload relief valve not at specified

pressure.

Check the overload relief valve and repair

as required.

(2) Control valve or bucket section spool

malfunctioning.

Check the spool and repair as required.

(3) Pilot valve defective.

Measure the secondary pressure and

check the pilot valve.

(4) Bucket cylinder rod packing broken.

Overhaul the cylinder and replace the

sealing.

Loading...

Loading...