U20-3, U25-3 WSM Machine body (Service section)

II-S-32

SERVICE PO

RT OPERA

TION

CAUTION

To avoid personal injury:

• Tilt the service port pedal forward when the

pedal is not used. Be sure to lock the pedal.

This pedal is used to operate attachments such as

breakers.

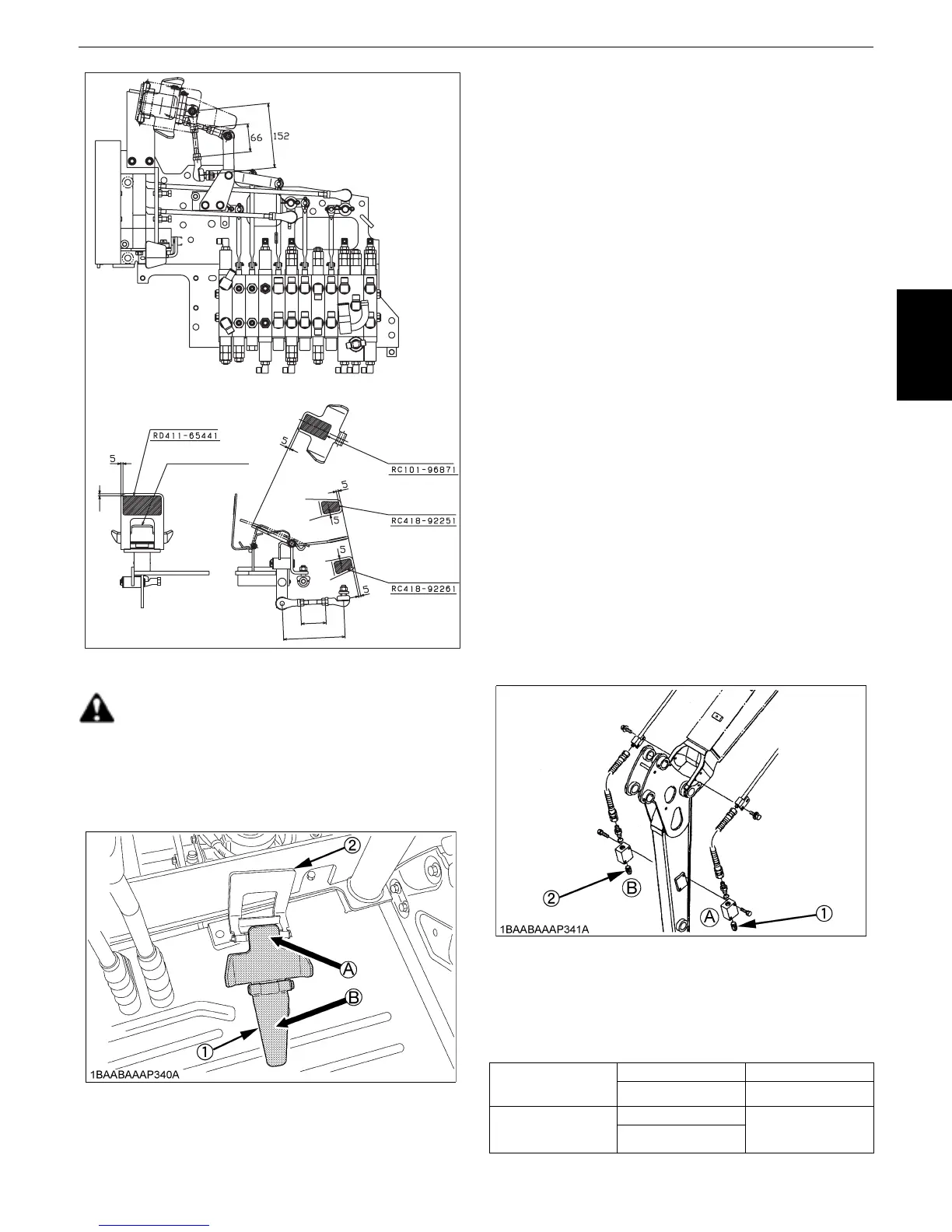

(1) Service port pedal

(2) Pedal lock

(A) Sends oil to the port (A)

(B) Sends oil to the port (B)

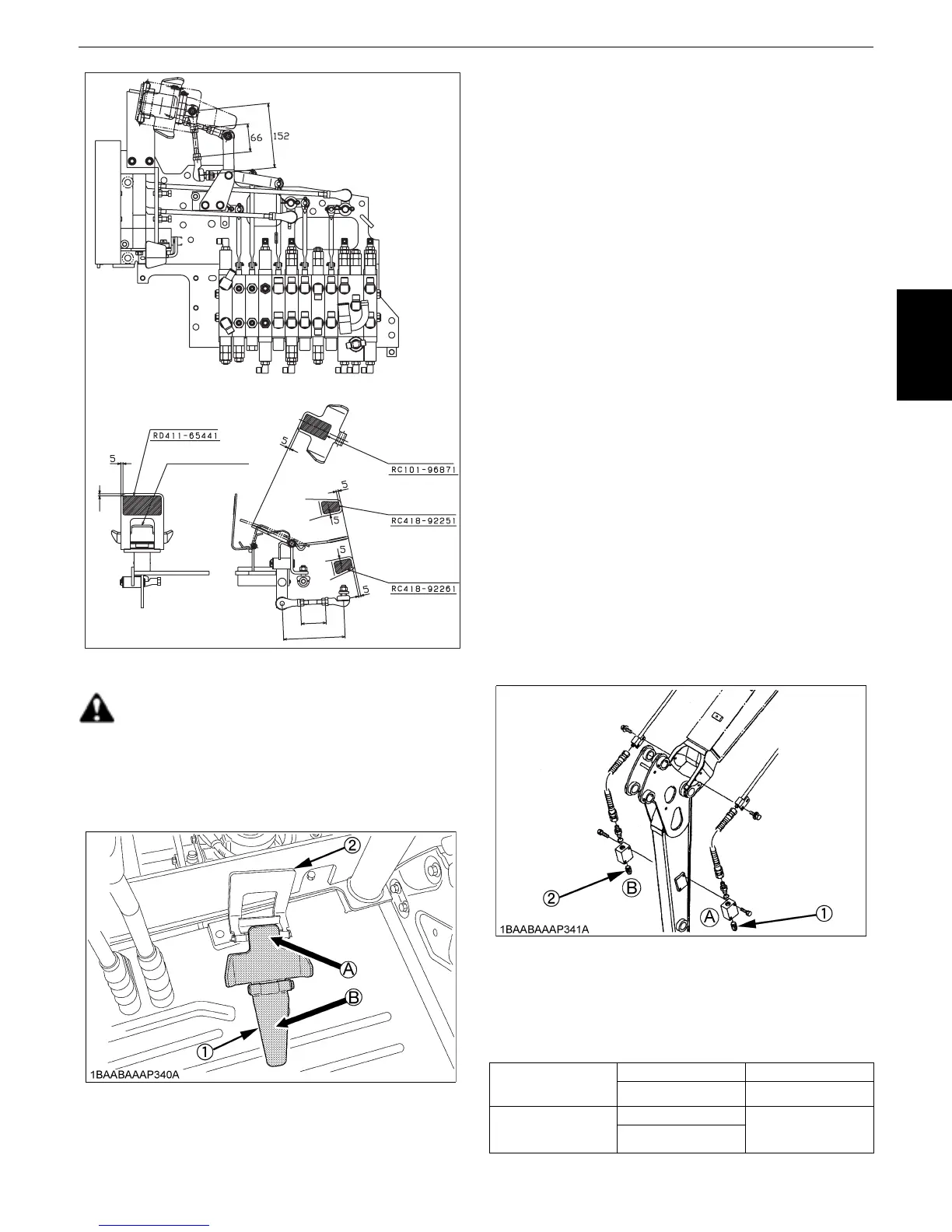

4. Make sure the pedal swings equally right

and left (horizontal at the center).

To and fro →Service port

Right and left →Swing

5. Fit the pedal with its top horizontal at the

neutral position.

6. Move both the service port and swing port

spools full stroke and release them. Now

make sure the pedal goes back smoothly to

its neutral position.

1) Assembling procedure

1. Adjusting the pedal

Make sure the pedal stays horizontal at the

center and swings equally right and left.

To and fro→Service port

Right and left→Swing

2. Tightening torque of link ball lock nut

39.2~45.1N·m (4.0~4.6kgf·m)

3. Link fitting dimensions

Fit the link as shown at left.

(1) Port (A)

(2) Port (B)

• Push the back part of the pedal (Ø) to send oil

to the port (A).

• Push the front part of the pedal (Ð) to send oil

the port (B).

Anti-slippage

Anti-slippage

Anti-slippage

(1)

Anti-slippage

(1, SP pedal)

Fit the pedal with

its top horizontal

at the neutral

position.

5 Actual fitting

60

146

Max. Flow

Volume

theoretical L min.

U20-3 35.8

U25-3 48.0

Max. Pressure

MPa

(kgf/cm

2

)

U20-3

21.6 (220)

U25-3

Loading...

Loading...