U20-3, U25-3 WSM Hydraulic system (Service section)

IV-S-7

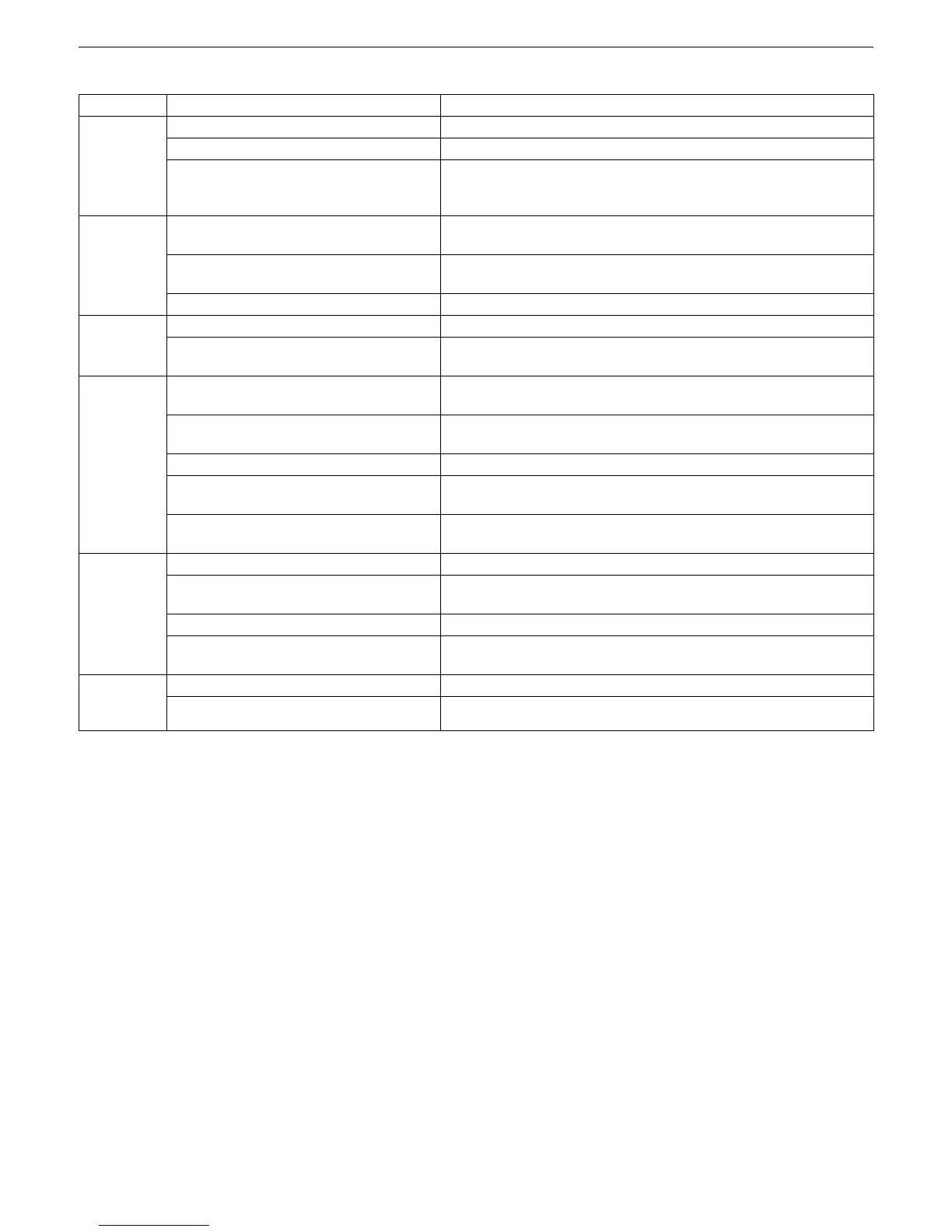

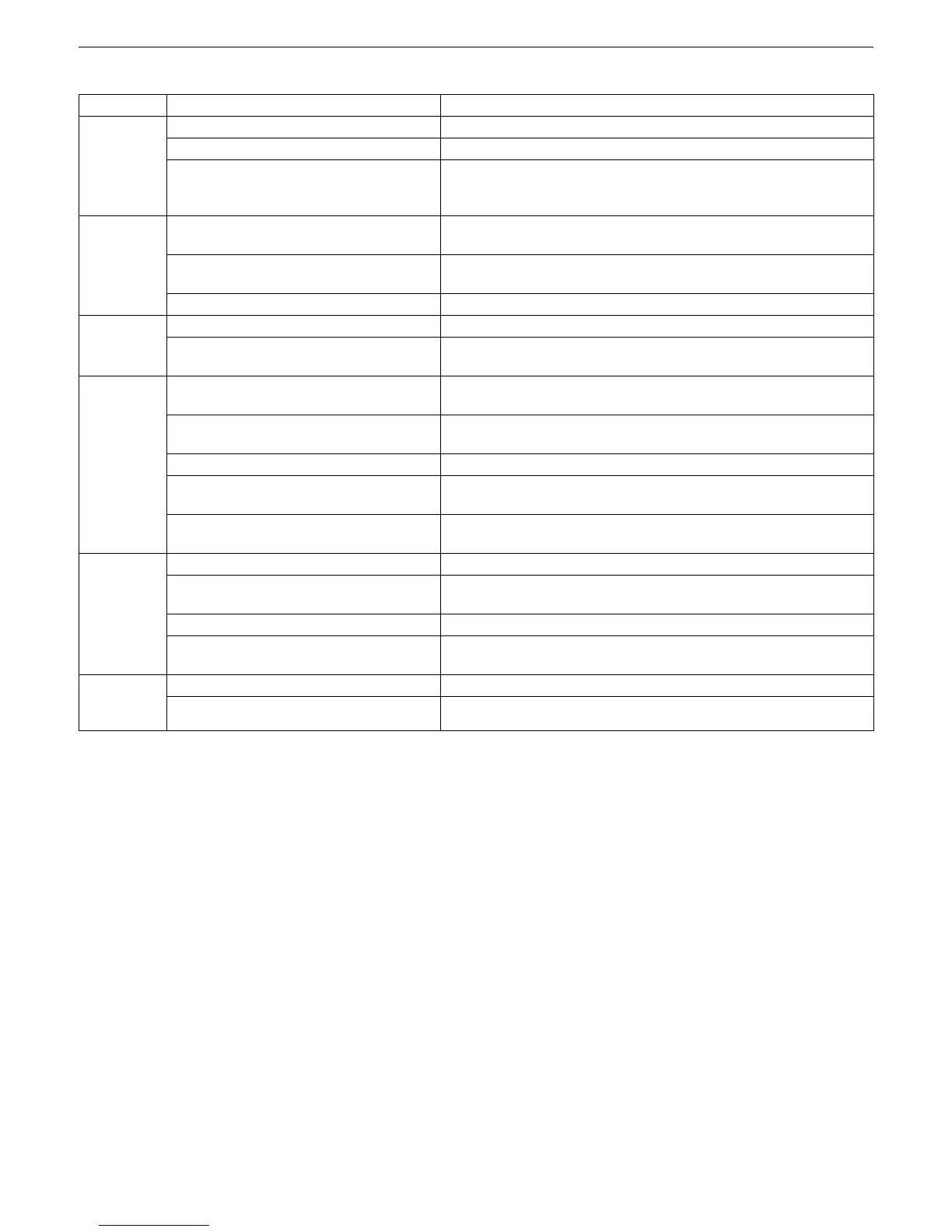

d. Motor

As listed above, there are various problems and their possible causes. The majority of troubles are,

however, caused by the entry of dust. Be very attentive not to allow any dust into the system.

Problem Cause Correction

Motor failure

to run

No pressure rise or no oil flow. Check the entire hydraulic circuit including the valves and pumps.

Oil viscosity inappropriate. Ensure the specified viscosity ranges.

Dust, degraded hydraulic oil, cavitation,

internal parts seized due to excessive radial

load, unusual contact, bearing damaged.

Run the motor alone and get it under a pressure of 30 kgf/cm

2

(2.9

MPa) or so. If it fails to run, then some internal parts might be seized

or damaged. Disassemble the motor and replace damaged parts.

Rpm not as

designed

Incoming flowrate too low.

Check the pump discharge rate, the motor rpm, and the valves for oil

leak.

Low viscosity and internal leak for oil

temperature or other reason.

Ensure the specified viscosity ranges.

Internal parts worn out. Replace worn-out parts.

Wrong

turning

direction

Wrong pipe connections. Reverse the pipe connections.

Poor valve timing due to wrong

disassembling/reassembling procedures.

Disassemble and reassemble again for good valve timing.

Oil leak

Oil seal scratched or worn.

Replace the oil seal. Repair or replace if the shaft seal contact

surface is scratched or worn.

Loose bolt or plug, resulting in oil leak (at

joints) from O-ring.

Tighten the bolt and plug to their specified torques. See also if the O-

ring is damaged. Replace the O-ring as required.

O-ring scratched or damaged. Replace the O-ring.

Dust or dent on the O-ring contact face.

Check for hit marks, burr, etc. Correct the surface with #600 or so

sandpaper. Replace the O-ring. Clean up and reassemble.

Cracked port, damaged screw.

Inappropriate joint.

Replace the housing. Use an appropriate joint and tighten it to the

specified torque.

Unusual

noise

Shaft poorly fitted. Center the shaft exactly.

Air left in the circuit or motor.

Let out the air completely. Fill the motor with oil and keep it running

under no load until there is no air bubbles in the tank.

Pump's cavitation. Unclog the suction filter.

Air mixed in the suction pipe line.

Apply oil or grease to each connection and carefully listen to the noise

there. If the noise is less, retighten the joint there.

Unusual

temperature

rise

Cooler in trouble. Repair the cooler.

Motor seized. Repair or replacement

Loading...

Loading...