6-13

Maintaining the Capping Station

6 6

Maintenance

Washing the Ink Discharge Passage (PUMP Tube Washing)

Wash the ink discharge passage regularly to prevent the head nozzles from clogging due to ink coagulation

inside the passage.

1

Press the key in LOCAL to select the

printing mode.

2

Select [ST. MAINTENANCE] of the maintenance menu.

(1)Press the key.

(2)Press to select [MAINTENANCE] and press the key.

3

Press the key.

4

Press to select [PUMP TUBE WASH].

5

Press the key.

• The carriage moves onto the platen.

• Repeat the idle absorbing operation (Absorption for 5 seconds and interruption for 10 seconds) until the

washing operation is completed.

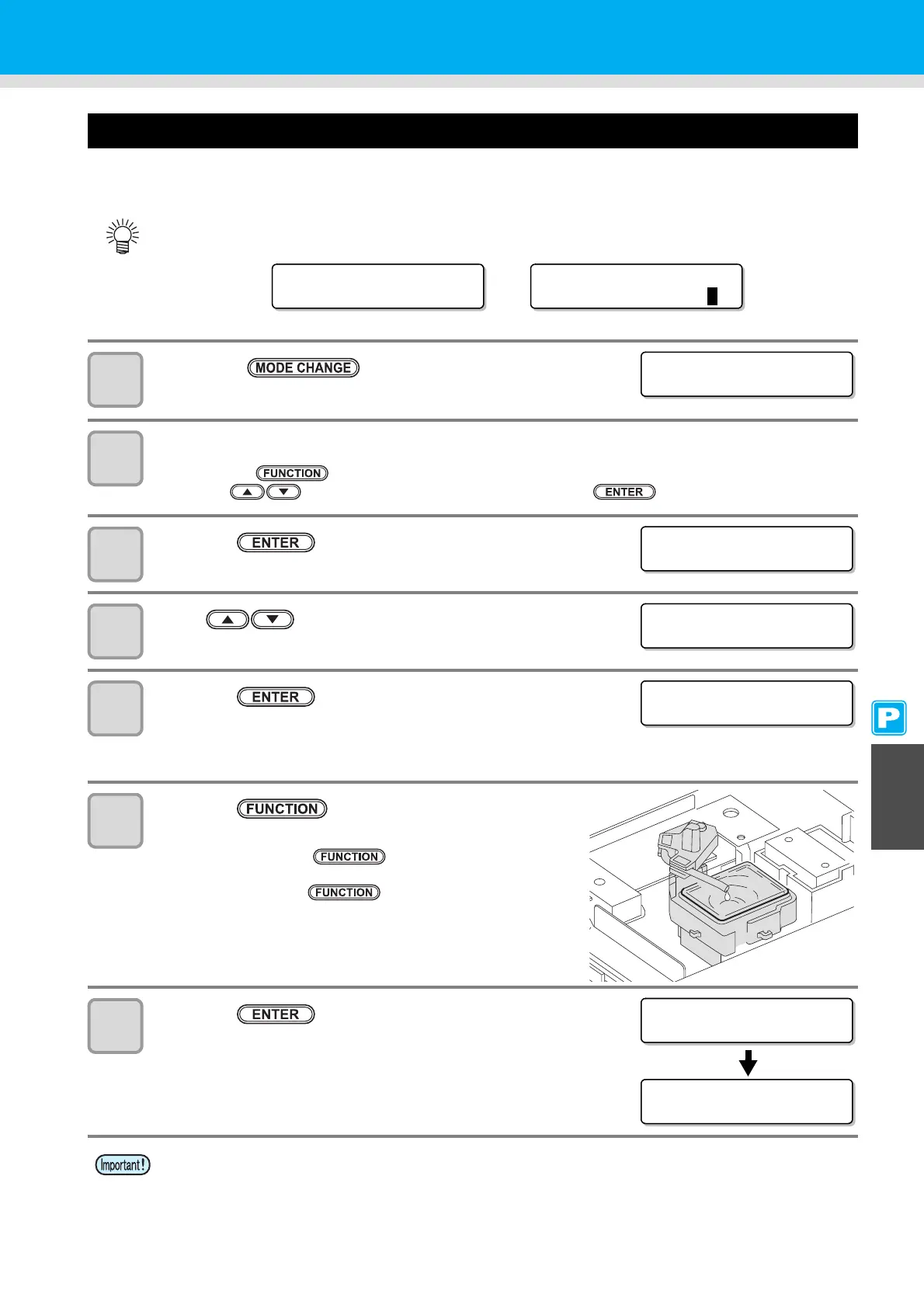

6

Press the key and fill up the cap with

cleaning solution for maintenance.

• When you press the key, cleaning solution drips

into the cap.

• When you press the key again, the solution stops

dripping.

• During the idle absorbing is interrupted, repeat the drops

several times to fill the cap with the cleaning solution just

before the solution overflows from the cap.

7

Press the key.

• After the idle absorbing operation has been performed for 30

seconds, the screen returns to LOCAL.

• When the following messages are displayed, check the waste ink tank and perform the operations

described on P.6-37 "If a Waste Ink Tank Confirmation Message Appears" as necessary.

• When this machine is not filled with cleaning solution for maintenance, do the following:

(1) Perform the operations in Steps 1 to 5.

(2) Fill up the cap with cleaning solution for maintenance, using a syringe.

(3) Perform the operation in Step 7.

Con f i rm a was t e tan k

Con t i nue< >Exchange

Con f i rm a was t e tan k

Exchange :

e nt

<LOCAL. 1> [ #01 ]

WIDTH:****mm

ST . MA I NTENANCE

CARR I AGE OUT < e n t >

ST . MA I NTENANCE

PUMP TUBE WASH < e n t >

ST . MA I NTENANCE

COMP L E TED : e n t

*Be i ng I n i t i a l i zed*

PLEASE WA I T

<LOCAL. 1> [ #01 ]

Loading...

Loading...